Mn-doped CsPbCl3 perovskite nano-crystals and preparation method thereof

A nanocrystal and perovskite technology, applied in nanotechnology, nano optics, nanotechnology, etc., can solve the problems of reduced Mn ion luminescence performance, uneven size of nanomaterials, and restrictions on practical applications, etc., to achieve uniform size and high quality , Good repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

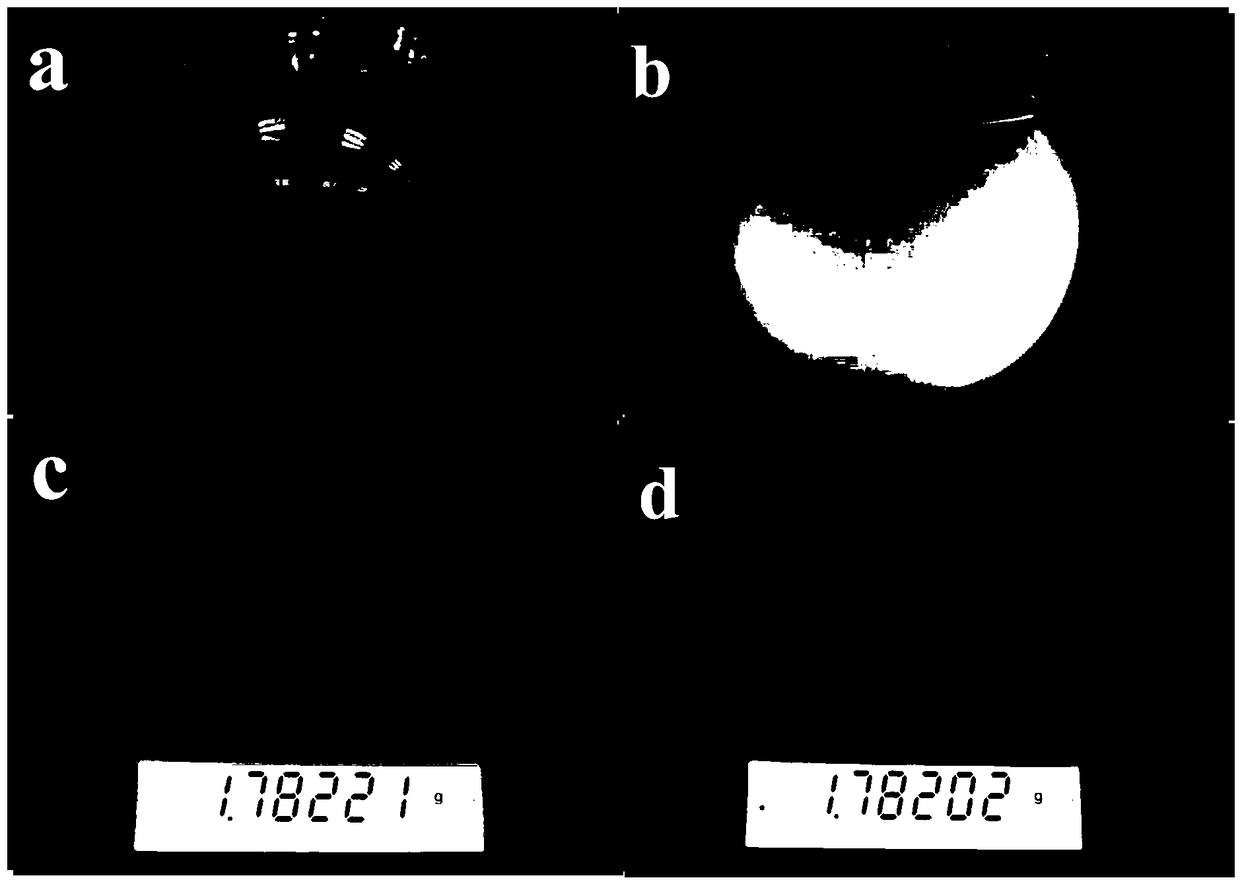

[0039] 0.8gCs 2 CO 3 , 2.4mL oleic acid (OA) and 30mL octadecene (ODE) were placed in a round bottom flask, heated to 120°C for 1 hour under vacuum, then heated to 150°C until Cs 2 CO 3 Dissolve completely to obtain the Cs precursor. Put 10mL oleylamine (OAm) and 1mL HCl in a 25mL round-bottomed flask, heat it up to 80°C for 1 hour under vacuum, then raise the temperature to 120°C for 2 hours to get RNH 3 Cl precursor.

[0040] Take 111mg PbCl 2 ,50mg MnCl 2 , 13mL ODE, 2mL DGBE, 2mL OA, 2mL OAm, 2mL TOP and 2mL RNH 3 The Cl precursor (heated to 100°C first) was placed in a 25mL round-bottomed flask, and the flask was placed in a microwave oven and heated by microwaves in an Ar atmosphere with a power of 400W. When the temperature rose to 150 °C, 0.85 mL of Cs precursor was heated to 100 °C and quickly injected into the above solution. After 5 seconds of reaction, the ice-water bath was taken out to cool down. The prepared Mn 2+ -CsPbCl 3 TEM images of perovskite nan...

Embodiment 2

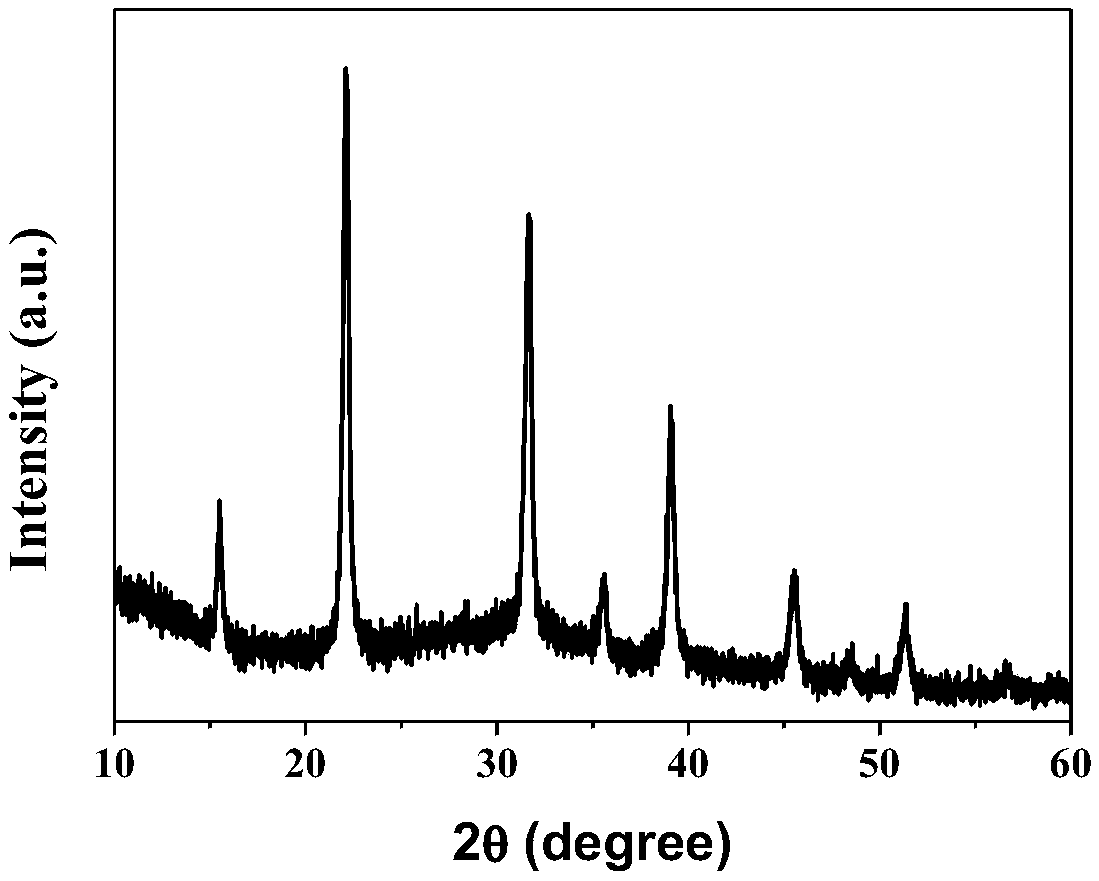

[0042] The only difference from Example 1 is that in this example, when microwave heating to 170°C in an Ar atmosphere, the Cs precursor is rapidly injected into the solution in the reaction bottle. stated. The Mn that this embodiment makes 2 + -CsPbCl 3 TEM images of perovskite nanocrystals image 3 , indicating that the prepared material is a cube, Figure 4 Its corresponding XRD pattern shows that the prepared Mn 2+ -CsPbCl 3 It is orthorhombic phase. As detected by inductively coupled plasma spectroscopy, the actual manganese doping concentration relative to Pb was 4.9% when the reaction temperature was 170 °C. Its fluorescence quantum yield is 39%.

Embodiment 3

[0044] The only difference from Example 1 is that in this example, when the microwave is heated to 190°C in an Ar atmosphere, the Cs precursor is rapidly injected into the solution in the reaction bottle. stated. The Mn that this embodiment makes 2 + -CsPbCl 3 TEM images of perovskite nanocrystals Figure 5 , indicating that the prepared material is a cube, Figure 6 Its corresponding XRD pattern shows that the prepared Mn 2+ -CsPbCl 3 It is orthorhombic phase. As detected by inductively coupled plasma spectroscopy, the actual manganese doping concentration relative to Pb was 6.5% when the reaction temperature was 190°C. Figure 7 Its corresponding fluorescence quantum yield calculation diagram shows that its fluorescence quantum yield is 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com