Flexible all-solid transparent supercapacitor with sandwich structure and preparation method thereof

A supercapacitor and sandwich technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of high cost, small capacitance, and complicated operation, and achieve low instrument requirements and high area ratio Capacitance, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

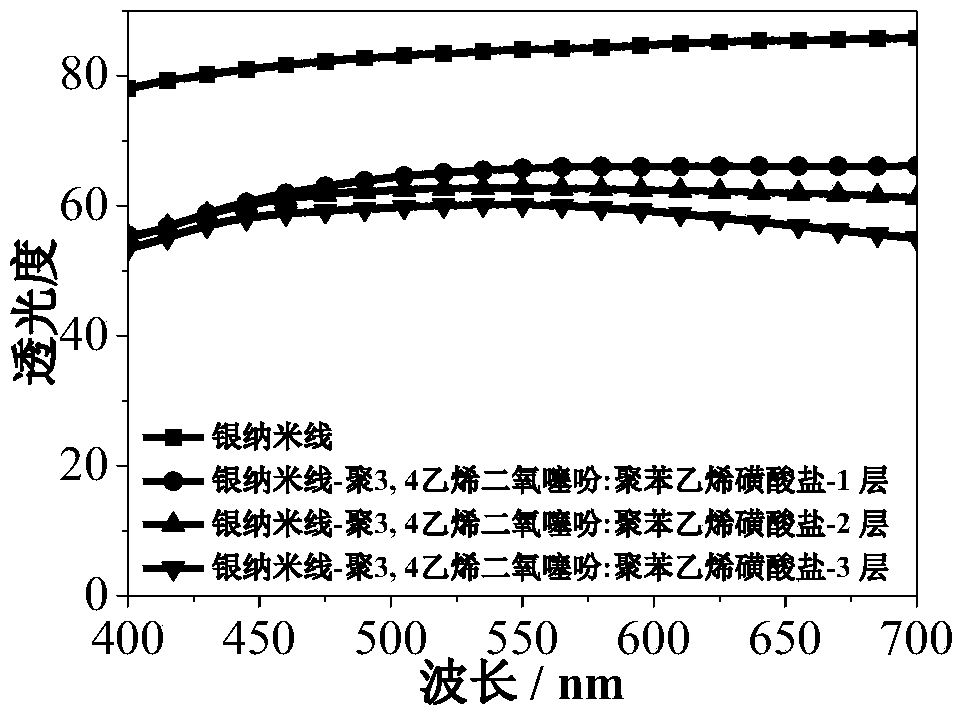

[0037] (1) Polyvinyl alcohol, H 3 PO 4 Add deionized water into a glass bottle and mix, then heat and stir at 95°C until a uniform gel electrolyte is formed; (2) Poly 3,4-ethylenedioxythiophene: polystyrene sulfonate (PEDOT:PSS) stock solution After filtering through a 0.5 μm water-based filter head, 6 vol% ethylene glycol and 2 vol% Triton (Triton-X 100) were added, and ultrasonically dispersed to form a uniform solution. (3) Cut out several PET sheets, and then plasma treat PET (100 w / 5min); (4) ultra-long silver nanowires (75 μm / 120nm) are uniformly dispersed in ethanol solution (0.36wt%), such as figure 1 As shown, then spin-coat twice (3000rpm / 60s) on the PET substrate, and anneal at 120°C for 15min to form a silver nanowire transparent electrode; (5) spin-coat PEDOT:PSS solution on the silver nanowire electrode subsequently ( 500rpm / 5s, 1500rpm / 55s), and then annealed at 120°C for 15min to prepare a composite electrode with a layer of PEDOT:PSS; A transparent and flex...

Embodiment 2

[0039] (1) Polyvinyl alcohol, phosphoric acid (H 3 PO 4 ) and deionized water were added to a glass bottle and mixed, then heated and stirred at 95°C until a uniform gel electrolyte was formed; (2) poly 3,4-ethylenedioxythiophene: polystyrene sulfonate (PEDOT:PSS) The stock solution was filtered through a 0.5 μm water-based filter head, and then 6 vol% ethylene glycol and 2 vol% Triton (Triton-X100) were added, and ultrasonically dispersed to form a uniform solution. (3) Cut out several PET sheets, and then plasma treat PET (100w / 5min); (4) Ultra-long silver nanowires (75μm / 120nm) are uniformly dispersed in ethanol solution (0.36wt%), and then on the PET substrate (500rpm / 5 s, 1500rpm / 55s), then annealed at 120°C for 15min, and repeated the same operation once to prepare a composite electrode with two layers of PEDOT:PSS, such as figure 2 As shown, PEDOT:PSS is annealed to form crystals covering the silver nanowires, forming a dense film; (6) Add electrolyte on two identi...

Embodiment 3

[0041] (1) Polyvinyl alcohol, phosphoric acid (H 3 PO 4 ) and deionized water were added to a glass bottle and mixed, then heated and stirred at 95°C until a uniform gel electrolyte was formed; (2) poly 3,4-ethylenedioxythiophene: polystyrene sulfonate (PEDOT:PSS) The stock solution was filtered through a 0.5 μm water-based filter head, and then 6 vol% ethylene glycol and 2 vol% Triton (Triton-X100) were added, and ultrasonically dispersed to form a uniform solution. (3) Cut out several PET sheets, and then plasma treat PET (100w / 5min); (4) Ultra-long silver nanowires (75μm / 120nm) are uniformly dispersed in ethanol solution (0.36wt%), and then on the PET substrate (500rpm / 5 s, 1500rpm / 55s), then annealed at 120°C for 15min, and repeated the same operation twice to prepare a composite electrode with three layers of PEDOT:PSS; (6) Add electrolyte on two identical composite electrodes, air-dry at room temperature, and then A transparent flexible supercapacitor with a sandwich...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com