Rechargeable metal-air battery with bifunctional carbon catalysis material as air electrode

A technology of air battery and air electrode, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, battery electrodes, circuits, etc., can solve the problems of rechargeable metal-air batteries that have not been reported, and achieve excellent results. Oxygen reduction and oxygen evolution electrochemical performance, excellent electrochemical performance, and the effect of easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

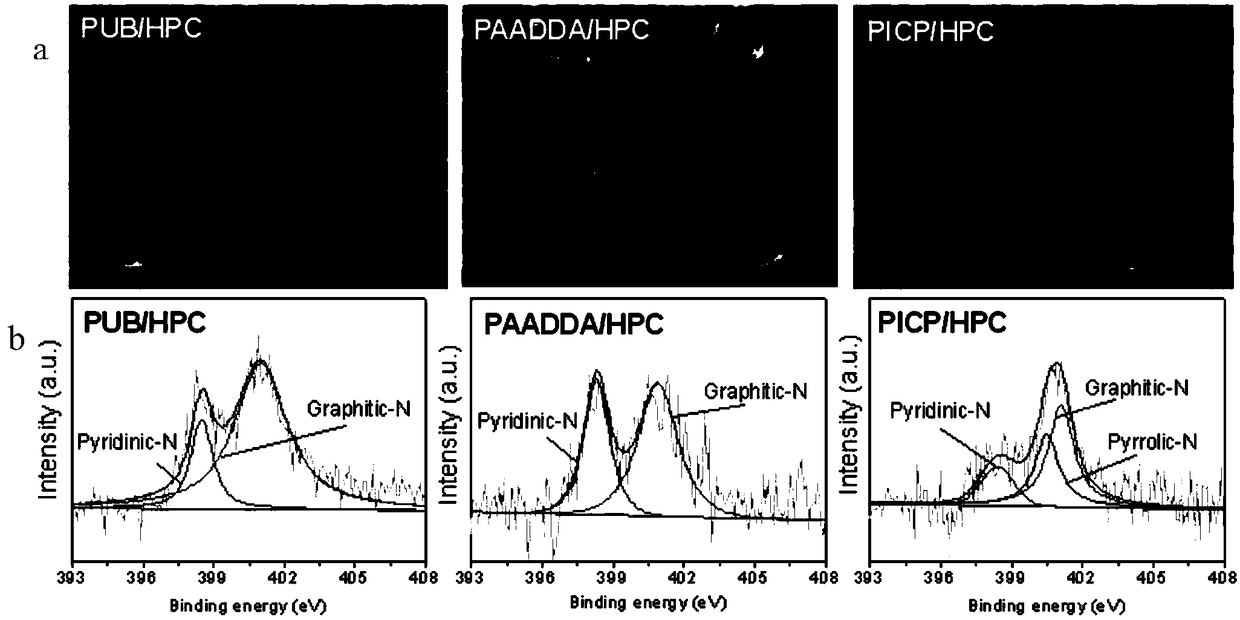

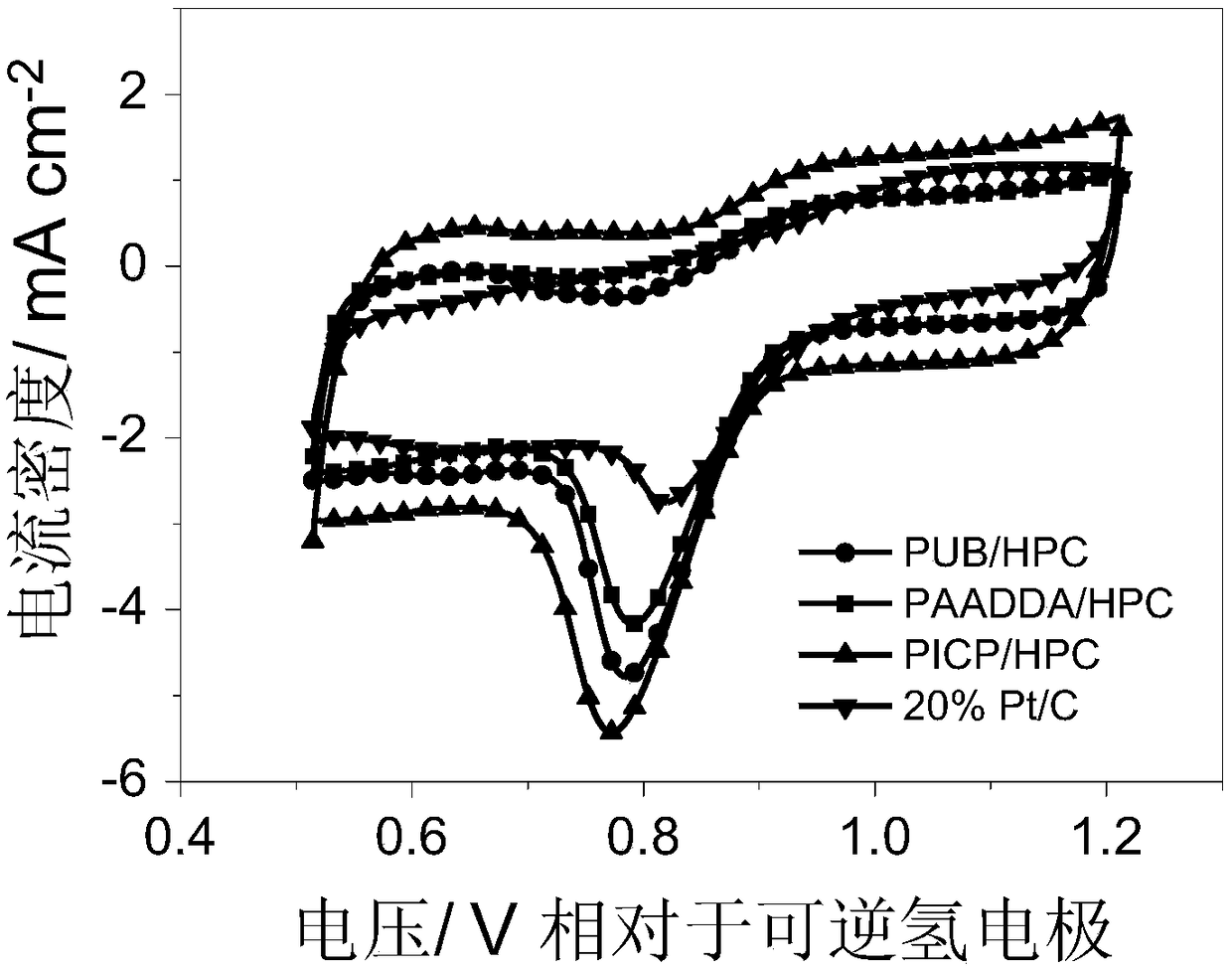

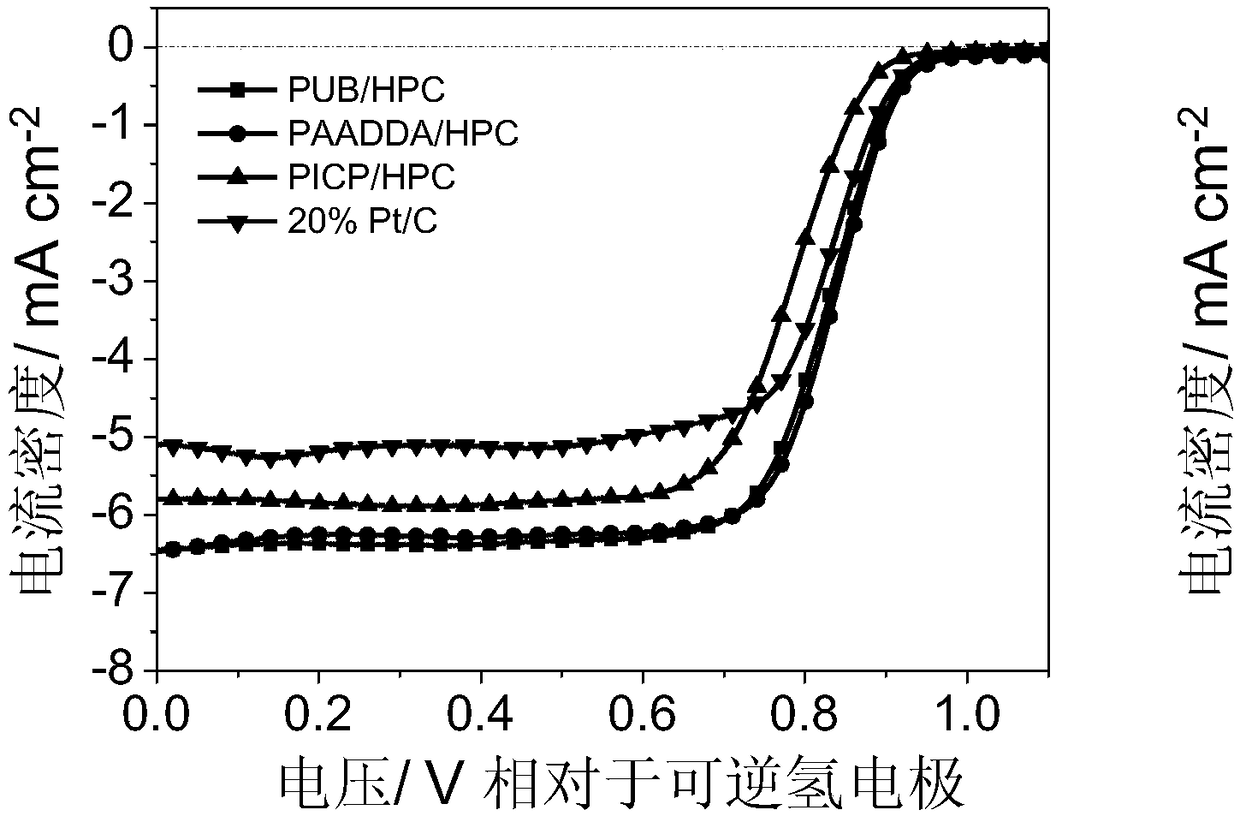

Embodiment 1

[0035] (1) Prepare a hydrochloric acid solution with a concentration of 1mol / L, weigh 3.63g of polyquaternized [bis(2-chloroethyl) ether-alt-1,3-bis[3-(dimethylamino)propyl] Urea] (abbreviated as PUB, Sigma aldrich company) was added to 42mL hydrochloric acid solution to make PUB solution; 5g silicon dioxide powder was weighed and added to 25mL hydrochloric acid solution to make SiO 2 Solution; Weigh 3g ferrous sulfate and add 10mL hydrochloric acid solution to make ferrous sulfate solution. The three solutions were mixed and ultrasonically dispersed for more than 10 min, and then magnetically stirred for more than 3 h. The uniformly mixed solution was dried in an oven at 85° C. for 48 hours, and then cooled to room temperature to obtain a reactant precursor.

[0036] (2) Grinding the reactant precursor in step (1) into powder, placing the powder in a quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 800°C at a heating rate of 20°C / ...

Embodiment 2

[0038] (1) preparation concentration is the hydrochloric acid solution of 1mol / L, takes by weighing 22.5g dimethyl diallyl ammonium chloride-acrylamide copolymer (being called for short PAADDA, Sigma aldrich company) and adds 42mL hydrochloric acid solution to make PAADDA solution; Take 5g of silicon dioxide powder and add 25mL of hydrochloric acid solution to make SiO 2 Solution; Weigh 3g ferrous sulfate and add 10mL hydrochloric acid solution to make ferrous sulfate solution. The three solutions were mixed and ultrasonically dispersed for more than 10 min, and then magnetically stirred for more than 3 h. The uniformly mixed solution was dried in an oven at 85° C. for 48 hours, and then cooled to room temperature to obtain a reactant precursor.

[0039] (2) Grinding the reactant precursor in step (1) into powder, placing the powder in a quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 800°C at a heating rate of 20°C / min, and heat ...

Embodiment 3

[0041] (1) Prepare a hydrochloric acid solution with a concentration of 1mol / L, and weigh 11.16g of Poly[(3-methyl-1-vinylimidazolium methyl sulfate)-co-(1-vinylcaprolactam)-co-(1-vinylpyrrolidone)] (PICP , Sigma aldrich company) add 42mL hydrochloric acid solution to make PICP solution; weigh 5g silicon dioxide powder and add 25mL hydrochloric acid solution to make SiO 2 Solution; Weigh 3g ferrous sulfate and add 10mL hydrochloric acid solution to make ferrous sulfate solution. The three solutions were mixed and ultrasonically dispersed for more than 10 min, and then magnetically stirred for more than 3 h. The uniformly mixed solution was dried in an oven at 85° C. for 48 hours, and then cooled to room temperature to obtain a reactant precursor.

[0042] (2) Grinding the reactant precursor in step (1) into powder, placing the powder in a quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 800°C at a heating rate of 20°C / min, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com