Tetrazine ring polycarbazole-based nitrogen-doped carbon-oxygen reduction catalyst and preparation method and application thereof

A nitrogen-doped carbon and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as low specific surface area and low ORR catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

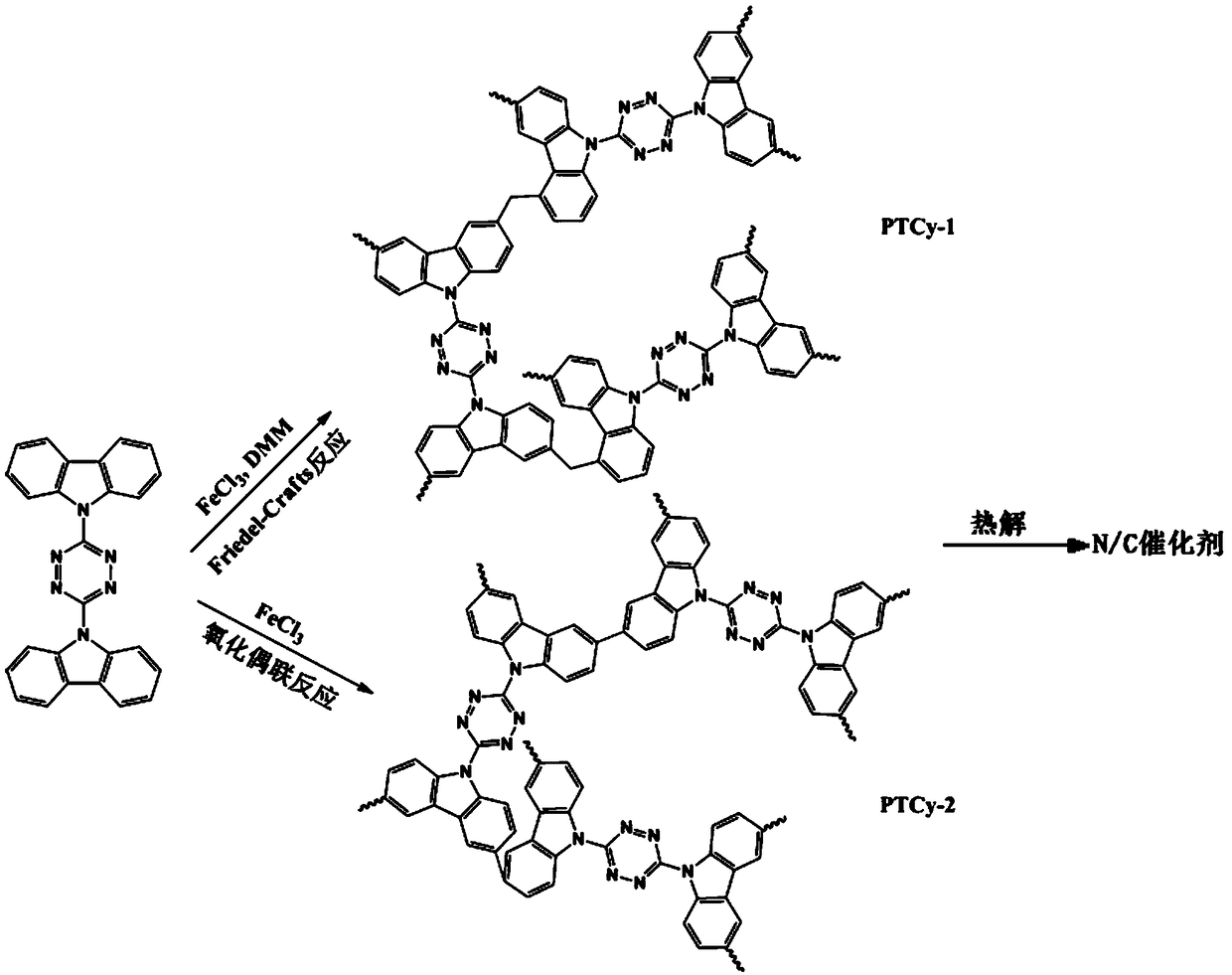

[0066] A nitrogen-doped carbon-oxygen reduction catalyst based on tetrazine ring polycarbazole, which is prepared by the following preparation method: first, 3,6-bis(3,5-dimethylpyrazole)-1,2 , 4,5-tetrazine prepared 3,6-bis(carbazolyl)-1,2,4,5-tetrazine (TCy) monomer by substitution reaction, and then 3,6-bis(carbazolyl) -1,2,4,5-Tetrazine (TCy) is obtained by Friedel-Crafts alkylation reaction to obtain tetrazine ring polycarbazole; then tetrazine ring polycarbazole is pyrolyzed to obtain tetrazine ring polycarbazole Nitrogen-doped carbon-oxygen reduction catalysts.

Embodiment 2

[0068]A nitrogen-doped carbon-oxygen reduction catalyst based on tetrazine ring polycarbazole, which is prepared by the following preparation method: first, 3,6-bis(3,5-dimethylpyrazole)-1,2 , 4,5-tetrazine prepared 3,6-bis(carbazolyl)-1,2,4,5-tetrazine (TCy) monomer by substitution reaction, and then 3,6-bis(carbazolyl) -1,2,4,5-tetrazine (TCy) can be obtained tetrazine ring polycarbazole through oxidative coupling reaction; then tetrazine ring polycarbazole is pyrolyzed to obtain tetrazine ring polycarbazole-based nitrogen-doped Heterocarbon oxygen reduction catalyst.

Embodiment 3

[0070] A method for preparing a nitrogen-doped carbon-oxygen reduction catalyst based on tetrazine ring polycarbazole, comprising the following steps:

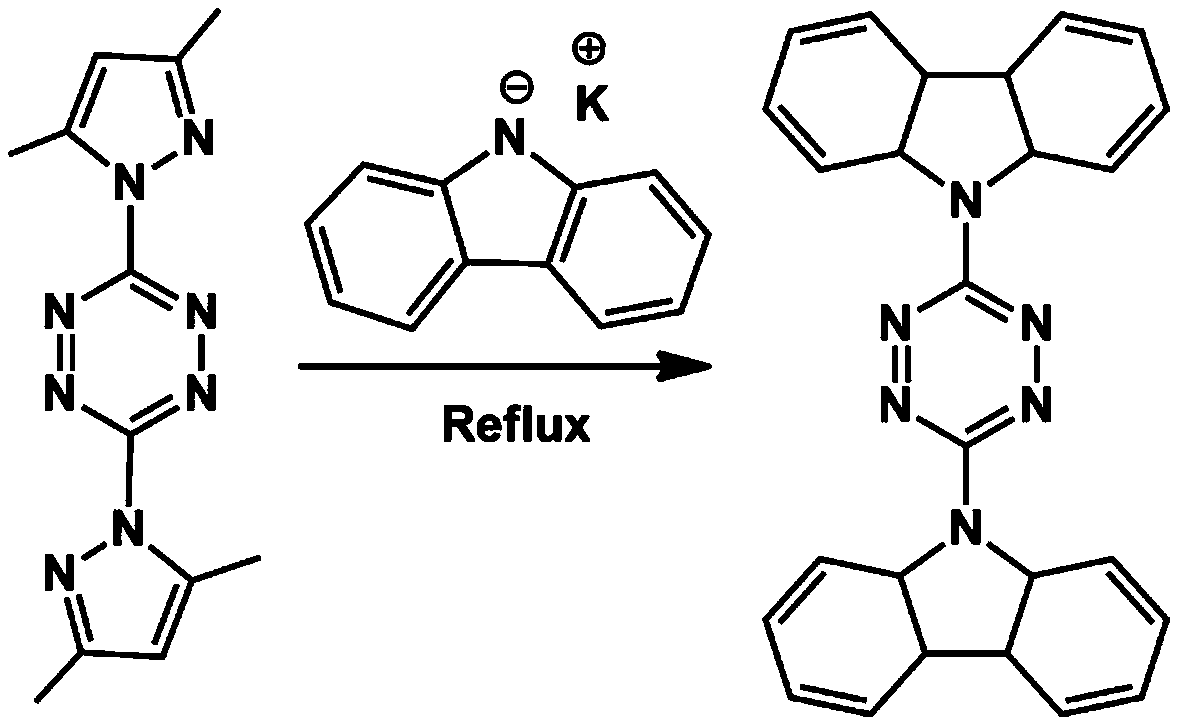

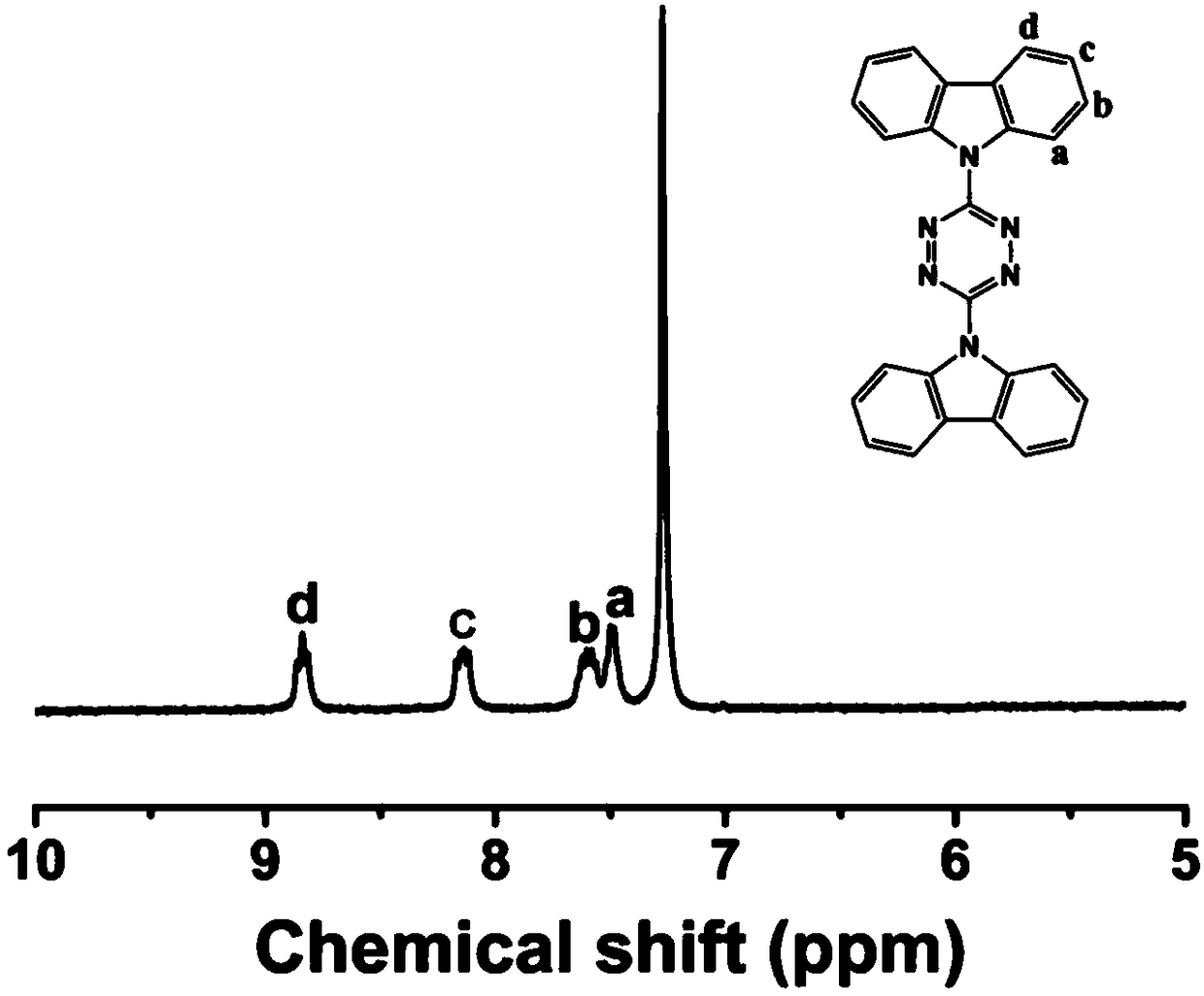

[0071] (1) Preparation of 3,6-bis(carbazolyl)-1,2,4,5-tetrazine (TCy): add 10mmol 3,6-bis(3,5-dimethylpyrazole) -1,2,4,5-tetrazine suspension in acetonitrile was added to the flask with 22mmol carbazole salt (preparation method: carbazole was added KOH at 0°C, stirred for 5h), stirred at room temperature for one hour, refluxed for 8h; cooled to At room temperature, filter, wash with acetonitrile and dry, and finally pass through the column with petroleum ether / chloroform; figure 2 is the composite map of TCy, image 3 is the NMR map of TCy;

[0072] (2) Synthesis based on 1,2,4,5-tetrazine ring polycarbazole hypercrosslinked polymer network (PTCy-1): add 40mmol dimethoxymethane to the nitrobenzene solution system of 10mmolTCy, stir 30min, then 40mmol FeCl 3 Added to the reaction system, and reacted at 45°C for 5h, and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com