Preparation method and functionalization process for fiber-reinforced hollow nanofiber membrane

A nanofiber membrane and fiber-reinforced technology, which is applied in the fields of fiber chemical characteristics, chemical instruments and methods, and rayon manufacturing, can solve the problems of being unsuitable for universal promotion, cumbersome preparation methods, and unsatisfactory effects, and achieve an excellent interface The effect of combining properties, excellent mechanical properties, and excellent catalytic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Use a 24-spindle two-dimensional braiding machine to weave a bundle of 400D polymphenylene isophthalamide (PMIA) filaments into a PMIA tubular braid with a diameter of 1.5 mm as a reinforcement;

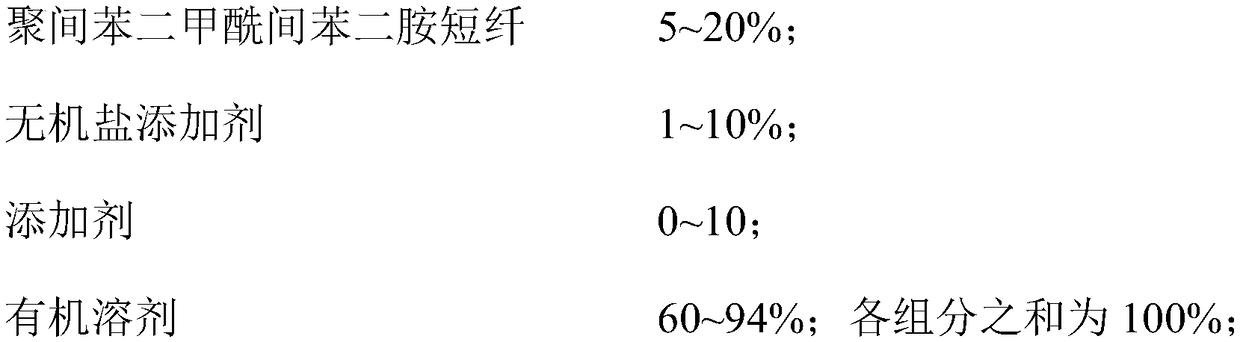

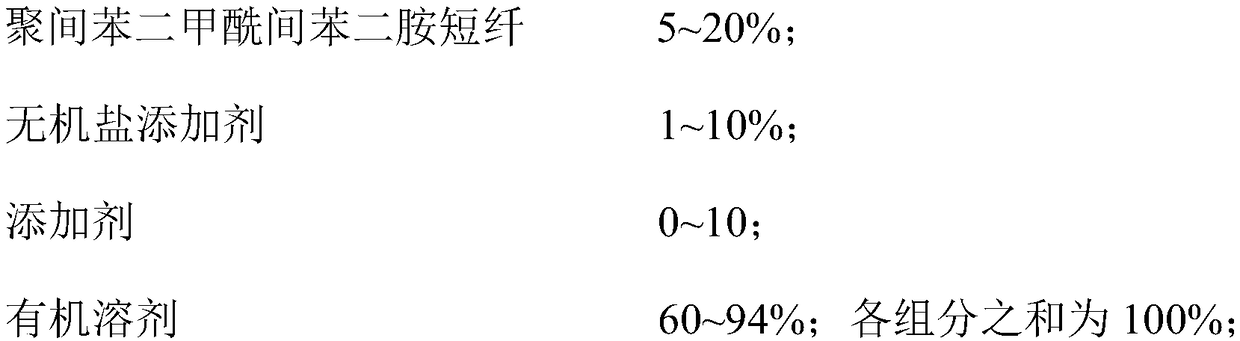

[0039] 2) Use the following method to prepare a solution for electrospinning. Dissolve lithium chloride (LiCl) in N,N-dimethylacetamide (DMAc), add PMIA, stir fully at 70°C until completely dissolved, That is, the solution for electrospinning is obtained;

[0040] Among them, the mass fractions of LiCl, DMAc and PMIA are 2%, 86%, 12% respectively;

[0041] 3) After defoaming the electrospinning solution obtained in step 2), place it in the electrospinning equipment, place the reinforcing body on the stainless steel filament, as the receiver of the electrospinning equipment, and perform electrospinning under the following conditions Silk: Electrospinning time is 10min, spinning temperature is 20°C, spinning relative humidity is 60%, spinning positive high voltage is 15kV, n...

Embodiment 2

[0045] 1) Use a 24-spindle two-dimensional braiding machine to weave a bundle of polyester filaments with a specification of 400D into a tubular braid with a diameter of 1.1 mm as a reinforcement;

[0046] 2) Use the following method to prepare a solution for electrospinning. Dissolve lithium chloride (LiCl) in N,N-dimethylacetamide (DMAc), add PMIA, stir fully at 70°C until completely dissolved, That is, the solution for electrospinning is obtained;

[0047] Among them, the mass fractions of LiCl, DMAc and PMIA are 2%, 86%, 12% respectively;

[0048] 3) After defoaming the electrospinning solution obtained in step 2), place it in the electrospinning equipment, place the reinforcing body on the stainless steel filament, as the receiver of the electrospinning equipment, and perform electrospinning under the following conditions Silk: Electrospinning time is 30min, spinning temperature is 20°C, spinning relative humidity is 65%, spinning positive high voltage is 20kV, negative ...

Embodiment 3

[0051] 1) Use a 24-spindle two-dimensional braiding machine to weave a bundle of polyester filaments with a specification of 400D into a tubular braid with a diameter of 1.1 mm as a reinforcement;

[0052] 2) Use the following method to prepare a solution for electrospinning. Dissolve lithium chloride (LiCl) in N,N-dimethylacetamide (DMAc), add PMIA, stir fully at 70°C until completely dissolved, That is, the solution for electrospinning is obtained;

[0053] Among them, the mass fractions of LiCl, DMAc and PMIA are 2%, 83%, and 15% respectively;

[0054] 3) After defoaming the electrospinning solution obtained in step 2), place it in the electrospinning equipment, place the reinforcing body on the stainless steel filament, as the receiver of the electrospinning equipment, and perform electrospinning under the following conditions Silk: Electrospinning time is 60min, spinning temperature is 20°C, spinning relative humidity is 65%, spinning positive high voltage is 20kV, negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com