Selective laser melting formed graphene reinforced aluminum-based composite material and preparation method thereof

A technology of selective laser melting and composite materials, applied in additive processing, additive manufacturing, metal processing equipment, etc., can solve the problems of poor wettability between graphene and aluminum matrix, affecting the mechanical properties of composite materials, and low graphene content, etc. Achieve the effect of saving materials and energy, shortening working hours, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

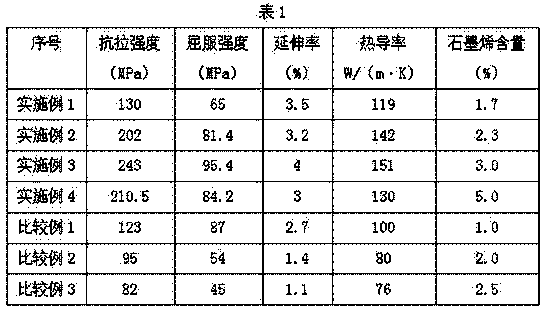

Examples

Embodiment 1

[0026] A selective laser melting graphene aluminum matrix composite material, the preparation method is as follows:

[0027] 1) Put 2g of graphene and 0.06g of stearic acid in a beaker, add 400ml of ethanol and ultrasonically disperse in an ultrasonic machine to obtain a mixed powder, and freeze-dry the mixed powder; among them, the ultrasonic dispersion time is 0.5h, and freeze-dried Temperature -50℃, freeze-drying time 2h;

[0028] 2) Put the dried powder, spherical silicon powder, and stearic acid in step 1) in a ball mill, fill it with liquid nitrogen and quench it for a period of time, and then conduct vacuum ball milling to obtain modified graphene; modified graphene and silicon The mass ratio of the powder is 1:6, the stearic acid is 1wt% of the spherical silicon powder, the liquid nitrogen quenching time is 0.5 hours, the ball-to-material ratio: 5:1, the speed: 100rpm, and the ball mill is 1h;

[0029] 3) Put the modified graphene, high-purity spherical aluminum powde...

Embodiment 2

[0033] A selective laser melting graphene aluminum matrix composite material, the preparation method is as follows:

[0034] 1) Put 2g of graphene and 0.06g of stearic acid in a beaker, add 400ml of ethanol and ultrasonically disperse in an ultrasonic machine to obtain a mixed powder, which is freeze-dried; the ultrasonic dispersion time is 2h, and the freeze-drying temperature is -40°C. Freeze drying time 6h;

[0035] 2) Put the dried powder, spherical silicon powder, and stearic acid in step 1) in a ball mill, fill it with liquid nitrogen and quench it for a period of time, and then conduct vacuum ball milling to obtain modified graphene; modified graphene and high The mass ratio of pure silicon powder is 1:5, the stearic acid is 1wt% of the spherical silicon powder, the liquid nitrogen quenching time is 2 hours, the ball material ratio: 7:1, the speed: 200rpm, the ball mill: 2h;

[0036] 3) Put the modified graphene, high-purity spherical aluminum powder, and stearic acid ...

Embodiment 3

[0040] A selective laser melting graphene aluminum matrix composite material, the preparation method is as follows:

[0041] 1) Put 2g of graphene and 0.06g of stearic acid in a beaker, add 400ml of ethanol and ultrasonically disperse in an ultrasonic machine to obtain a mixed powder, which is freeze-dried; wherein, the ultrasonic dispersion time is 4h, and the freeze-drying temperature is -20°C. Freeze drying time 8h;

[0042] 2) Put the dried powder, spherical silicon powder, and stearic acid in step 1) in a ball mill, fill it with liquid nitrogen and quench it for a period of time, and then conduct vacuum ball milling to obtain modified graphene; graphene and high-purity silicon The mass ratio of the powder is 1:4, the stearic acid is 1wt% of the spherical silicon powder, the liquid nitrogen quenching time is 4h, the ball-material ratio: 6:1, the speed: 250rpm, and the ball milling is 2.5h;

[0043]3) Put the modified graphene, high-purity spherical aluminum powder, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com