Silicone rubber synthetic leather and production technology thereof

A technology of silicone rubber and production process, which is applied in the field of synthetic leather, can solve the problems of poor appearance, environmental pollution, single color, etc., and achieve the effect of beautiful appearance and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

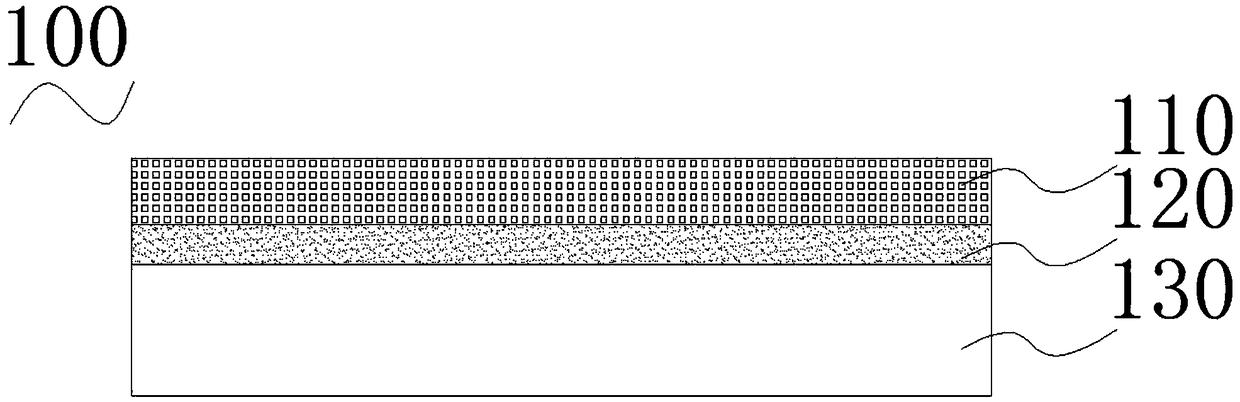

[0023] Such as figure 1 Shown is a schematic cross-sectional view of the present invention.

[0024] Silicone rubber synthetic leather 100, from top to bottom includes top rubber layer 110, bottom rubber layer 120 and substrate 130; The top rubber layer 110 includes the following components in mass fraction, dimethyl hydrogen siloxane polymer 0.1-60%, vinyl siloxane polymer 1-20%, silicon dioxide 0.1-20%, vinyl silicone resin 0.1-10%, platinum catalyst 0.01-1%, inhibitor 0.001-0.1%, color paste 0-0.1%; the primer layer 120 includes the following components in mass fraction, dimethylhydrogensiloxane polymer 0.1-80%, polymethylsilsesquioxane 0.01-1%, vinyl silicone Alkane polymer 1-20%, trimethylsilane 2-8%, platinum catalyst 0.01-1%, inhibitor 0.001-0.1%, color paste 0-0.1%.

[0025]The substrate 130 includes the following components by mass fraction, 3-15% of 1,5-naphthalene diisocyanate, 5-20% of diphenylmethane-4,4'-diisocyanate, 20-35% of polyoxyethylene diol %, polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com