Production technology and system of vanadium redox battery electrolyte

A production process and electrolyte technology, applied in the production process and system field of vanadium battery electrolyte, can solve the problems affecting the stability and durability of all-vanadium redox flow batteries, the high production cost of commercial vanadium electrolyte, and the addition of reducing agents. It is difficult to control the amount and other problems, so as to achieve the effect of easy industrial production, lower production cost and small reaction interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all embodiments. Based on the embodiments of the present invention, those skilled in the art All other embodiments obtained by personnel without creative work belong to the protection scope of the present invention.

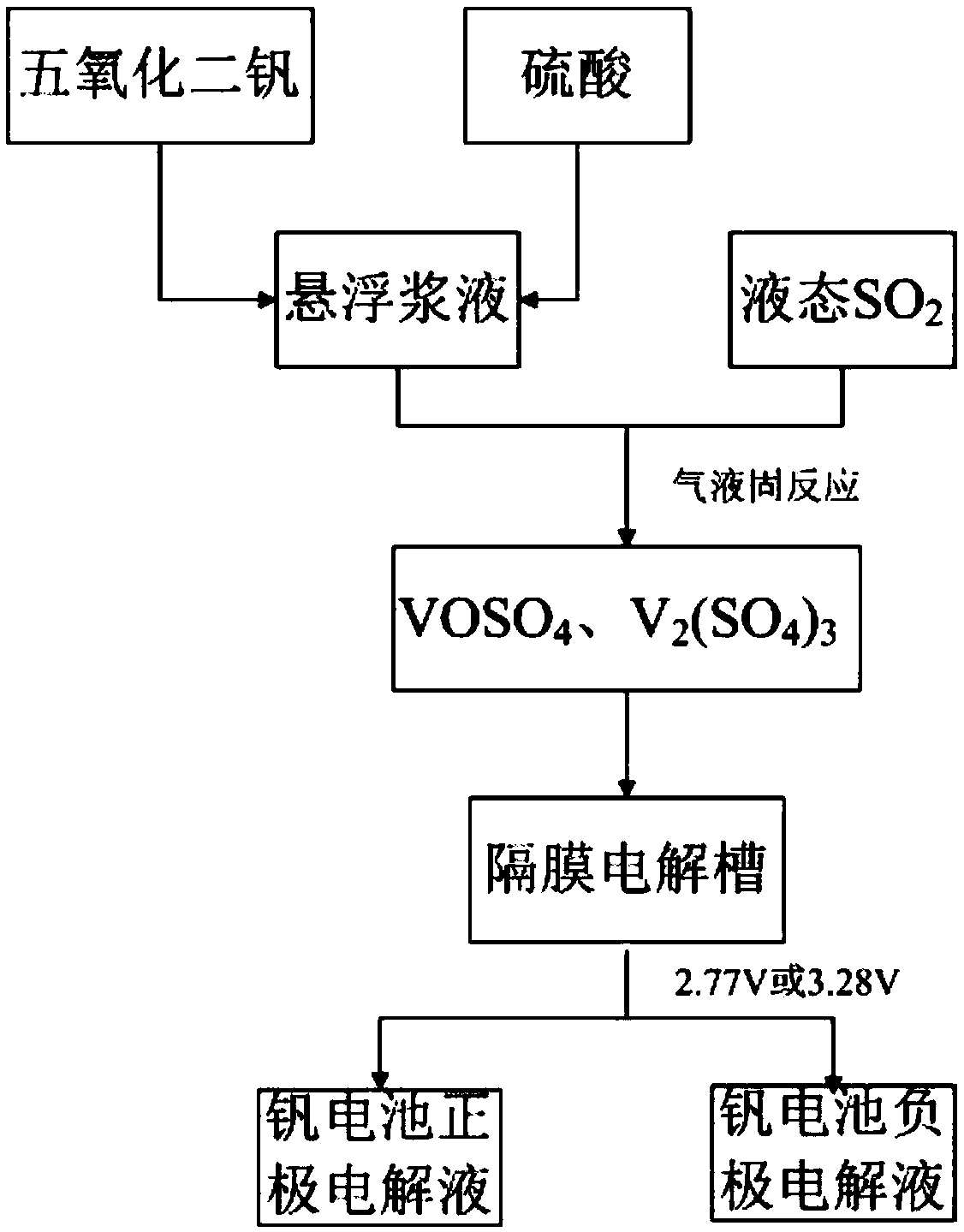

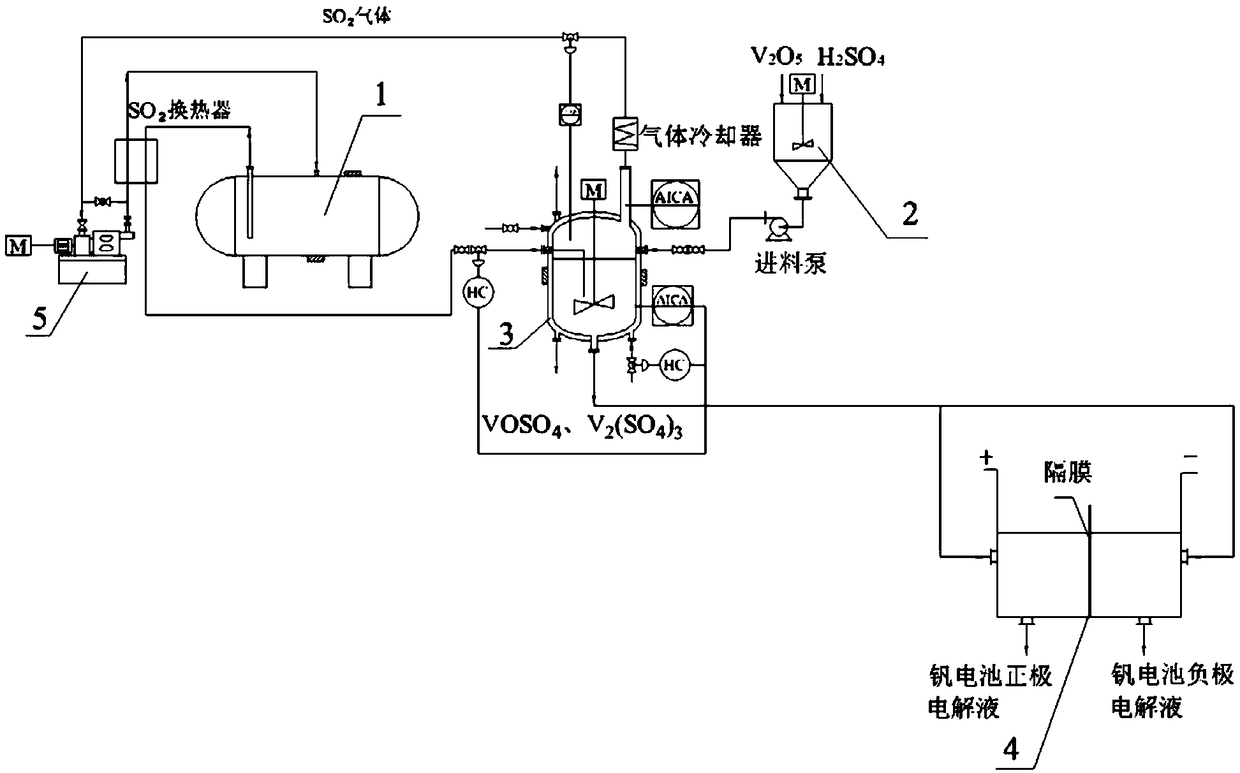

[0054] Such as figure 1 Shown, the production technique of vanadium battery electrolyte of the present invention comprises the following steps:

[0055] (1) Put pure V in the conical bottom preparation tank 2 o 5 Mix with sulfuric acid solution (30%), obtain suspension slurry (control V 2 o 5 The mass concentration is 40%), the suspension slurry is added in the jacket reactor with the feed pump, the suspension slurry added is no more than 1 / 2 of the reactor, and the feed pump is closed;

[0056] (2) Turn on the stirring motor of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com