Titanium silicalite molecular sieve and preparation and application thereof

A technology of titanium-silicon molecular sieve and silicon source, which is applied in the direction of molecular sieve compounds, molecular sieve catalysts, molecular sieve characteristic silicates, etc., can solve the problems of cost increase and synthesis cost increase, and achieve the reduction of the burden of alcohol removal, low price and rich synthesis The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 46.2g of tetraethyl orthosilicate to the beaker and stir, then add 44g of 25wt% TPAOH aqueous solution and 38g of water, and hydrolyze at 30°C for 2h to obtain a silicon source hydrolysis mixture; add it to 0.52g of metatitanic acid, stirring conditions Then add 3.0g 30wt% H 2 o 2 aqueous solution and 10g of 25wt% TPAOH aqueous solution, and then stirred for 30min to obtain the titanium source hydrolysis mixture; the titanium source and the silicon source hydrolysis mixture were mixed, and alcohol was removed at 80°C for 1.5h, 50.2g of water was added and stirred for 30min, and the obtained The transparent glue was put into a crystallization kettle for crystallization, and crystallized at 170°C for 36 hours. After washing and drying, the obtained crystallized product was calcined at 540°C for 6 hours to obtain TS-1, which was designated as TS-1-B.

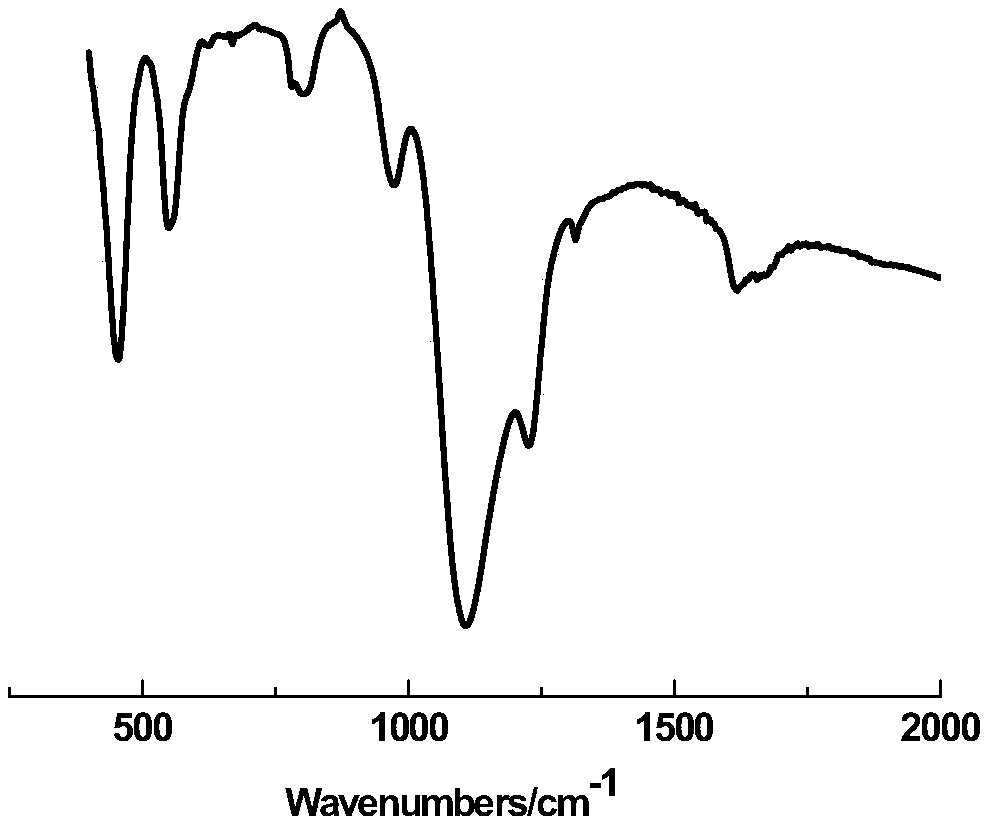

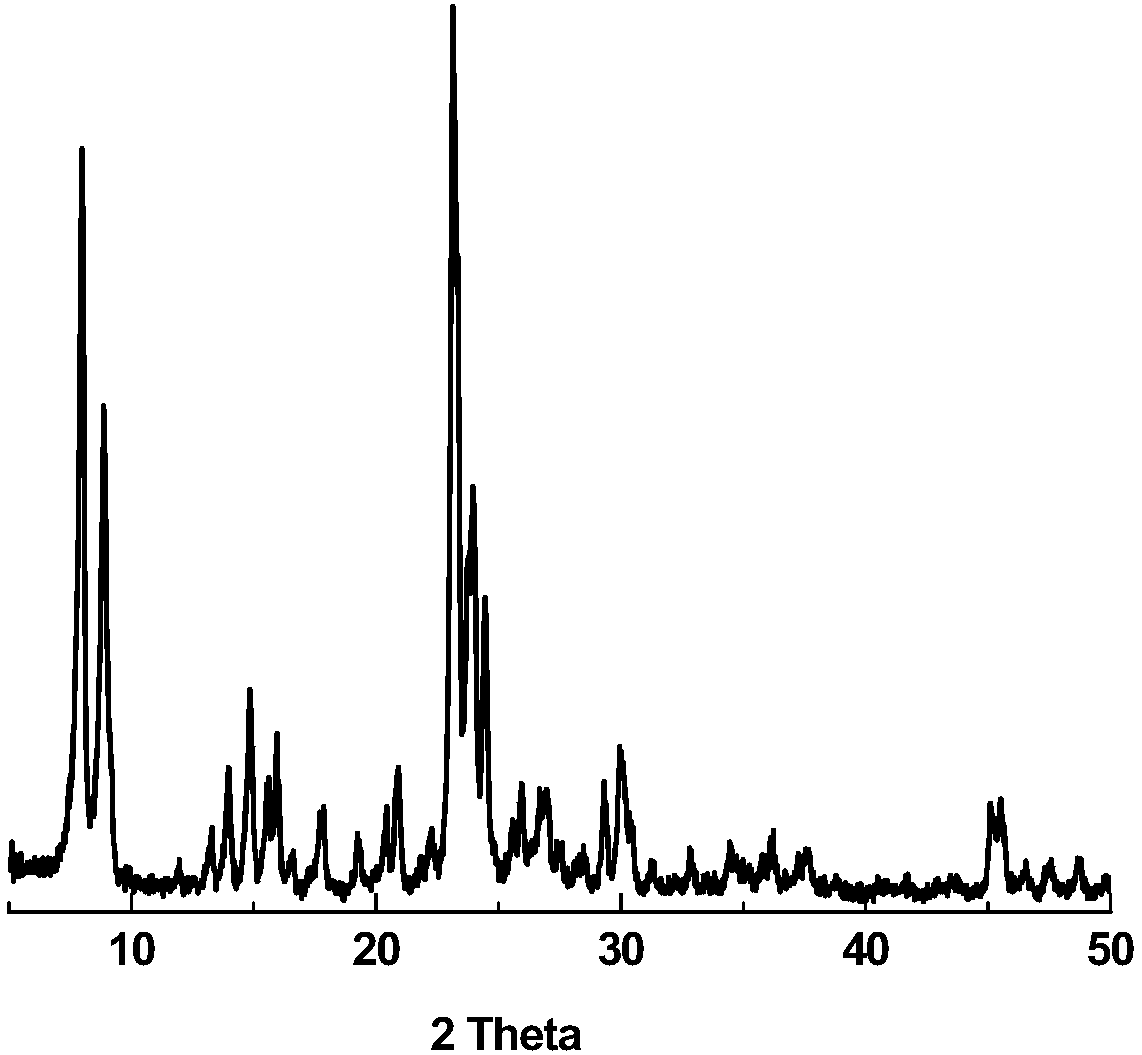

[0026] figure 1 It is the infrared absorption spectrum of TS-1-B, in the infrared spectrum at 960cm -1 The infrared...

Embodiment 2

[0029] Repeat the process in Example 1, just change the silicon source into silica sol, silica gel or fumed silica (white carbon black), keep the amount of the substance of silicon dioxide constant, after crystallization, through washing, drying, roasting Then get TS-1.

Embodiment 3

[0031] Repeat the process in Example 1, but change metatitanic acid to orthotitanic acid, keep the amount of titanium dioxide unchanged, after crystallization, obtain TS-1 after washing, drying and roasting, denoted as TS-1- c.

[0032] image 3 It is a scanning electron micrograph of TS-1-C, and it can be seen that the grain size of TS-1 is 100-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com