Fine processing method of biomass organic fertilizer

A fine processing, organic fertilizer technology, applied in the preparation of organic fertilizer, biological organic part treatment, organic fertilizer and other directions, can solve the problems of damage to the root of crops, slow, slow natural decomposition rate, etc., to promote carbon and nitrogen utilization, rapid dissolution Absorption and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

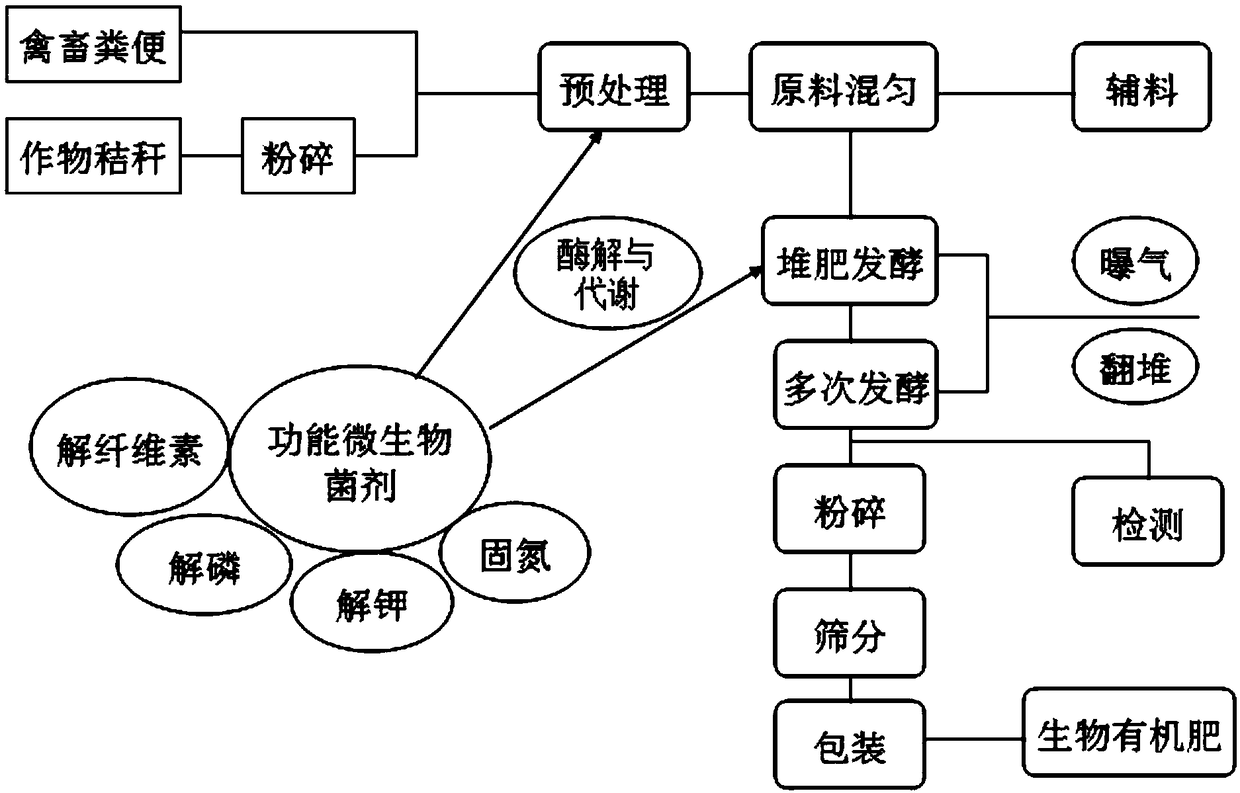

[0027] based on the following figure 1 The present invention is further described.

[0028] A kind of production process of organic fertilizer is as follows:

[0029] a) The pre-treatment of poultry manure selects pig manure with a moisture content of about 50% and chicken manure with a moisture content of about 3%. Add 1wt% of functional microbial agents to pig manure and chicken manure for fermentation to remove odor and bacteria in feces;

[0030] b) Treatment of straw raw materials Dried the collected rice straw raw materials and crushed them into 0.7cm sized particles for later use;

[0031] c) Initial fermentation: 35wt% of chicken manure, 45wt% of pig manure, 2.5wt% of straw particles, 2.5wt% of sawdust, 10wt% of functional microbial agent and 5wt% of additives are stirred in proportion with a mixer in steps a and b , and then use a forklift to turn over the pile to make the materials evenly mixed, and use a sterilizer to sterilize;

[0032] After the raw materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com