Low-VOC water-based industrial anticorrosive resin and preparation method and application thereof on coating

An anti-corrosion resin, water-based technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of salt spray resistance, poor corrosion resistance, long-term outdoor use, poor weather resistance, etc., to achieve high gloss, good toughness, fast surface drying and hard work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

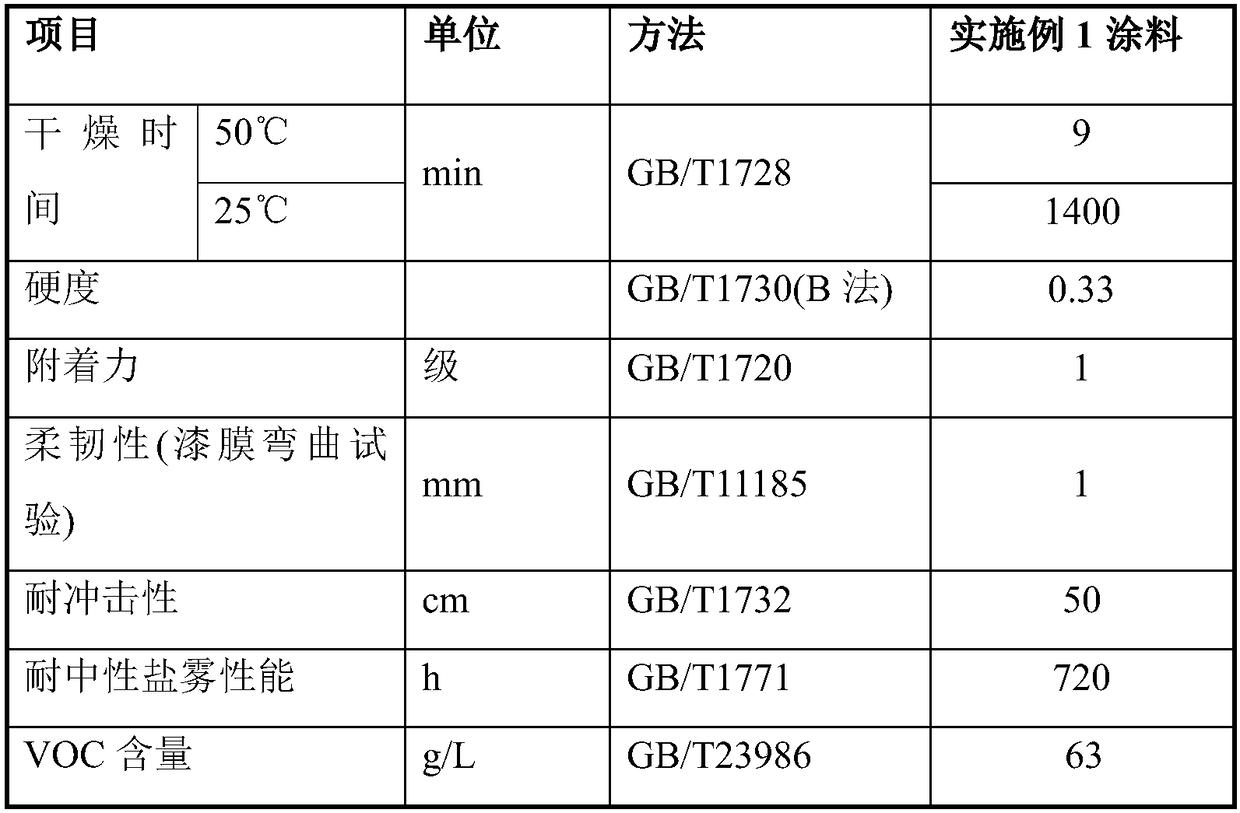

Embodiment 1

[0019] 1.1 Preparation of low VOC waterborne industrial anticorrosion resin

[0020] Recipe: 5 parts of E44 epoxy resin, 25 parts of acrylic acid, 3 parts of methyl methacrylate, 1 part of maleic anhydride, 0.5 parts of N,N-dimethylethanolamine, 0.5 parts of ammonium persulfate, 0.05 parts of l, 4-Naphthoquinone, 0.5 parts of triethanolamine, 3 parts of ethylene glycol butyl ether, 1 part of butanol, 1 part of dipropylene glycol methyl ether, 0.3 parts of Tween 80 and 40 parts of purified water.

[0021] Preparation: Add 5 parts of E44 epoxy resin into the reaction kettle, raise the temperature to 85°C at a speed of 300r / min, increase the speed to 1300r / min after the temperature is reached, add 25 parts of acrylic acid and 3 parts of methyl to the reaction kettle Methyl acrylate, 1 part of maleic anhydride, continue to heat up to 85 ° C under high-speed stirring, and slowly add 0.5 parts of N,N-dimethylethanolamine, 0.5 parts of ammonium persulfate and 0.05 parts of l, 4-napht...

Embodiment 2

[0029] 2.1 Preparation of low VOC waterborne industrial anticorrosion resin

[0030] Formula: 4 parts of E51 epoxy resin, 23 parts of acrylic acid, 2.5 parts of methyl methacrylate, 0.7 parts of maleic anhydride, 0.3 parts of N,N-dimethylethanolamine, 0.2 parts of ammonium persulfate, 0.05 parts of p-phenol , 0.35 parts of triethanolamine, 3 parts of ethylene glycol butyl ether, 3 parts of butanol, 0.2 parts of fatty acid polyoxyethylene ether and 35 parts of purified water.

[0031] Preparation: Add 4 parts of E-51 epoxy resin into the reactor, raise the temperature to 85°C at a speed of 300r / min, increase the speed to 1300r / min after the temperature is reached, add 23 parts of acrylic acid, 2.5 parts of Methyl methacrylate, 0.7 parts of maleic anhydride, continue to heat up to 85°C under high-speed stirring, and slowly add 0.3 parts of N,N-dimethylethanolamine, 0.2 parts of ammonium persulfate and 0.05 parts of p-phenol, and react for 5 hours After cooling to 45°C, add 0.35...

Embodiment 3

[0039] 3.1 Preparation of low VOC waterborne industrial anticorrosion resin

[0040] Recipe: 3 parts of E44 epoxy resin, 2 parts of E51 epoxy resin, 20 parts of acrylic acid, 1 part of methyl methacrylate, 1 part of maleic anhydride, 1 part of N,N-dimethylethanolamine, 0.02 parts of l , 4-naphthoquinone, 0.03 part of p-phenol, 0.3 part of triethanolamine, 2 parts of butanol, 1 part of dipropylene glycol methyl ether, 0.1 part of Tween 80, 0.1 part of fatty acid polyoxyethylene methyl ether and 35 parts of purified water.

[0041]Preparation: Add 3 parts of E-44 epoxy resin and 2 parts of E51 epoxy resin into the reaction kettle, raise the temperature by 85°C at a speed of 300r / min, increase the speed of 1300r / min after the temperature is reached, and pour into the reaction kettle Add 20 parts of acrylic acid, 1 part of methyl methacrylate, 1 part of maleic anhydride, continue to stir at a high speed and raise the temperature to 85 ° C, while slowly adding 1 part of N,N-dimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com