Preparation method of a covalent-microcrystalline-ionic triple interpenetrating network hydrogel

An interpenetrating network and semi-interpenetrating network technology, which is applied in the field of preparation of covalent-crystallite-ion triple interpenetrating network hydrogel, can solve the problems of poor mechanical properties of hydrogels, and can solve the problem of poor mechanical properties. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Add 10g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) into 10ml of deionized water, stir evenly, heat up to 50°C, take 0.05g of ammonium persulfate and 0.025g of sodium bisulfite and dissolve in 1ml An initiator solution was prepared in water, and the above-mentioned initiator solution was added to the AMPS aqueous solution, and reacted for 20 hours. Most of the water was evaporated, and dried in a vacuum oven to constant weight to obtain PAMPS solid, which was ground into powder and set aside.

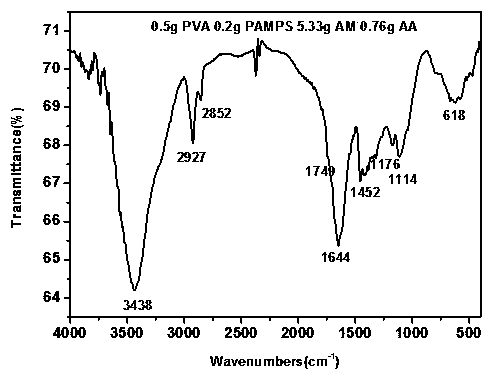

[0042] 2) Add 0.5g of polyvinyl alcohol (PVA) to 24ml of deionized water, heat to 95°C to dissolve, take 0.2g of PAMPS powder prepared in step 1) and add to the above solution, then add 5.33g of acrylamide (AM) , 0.9g of acrylic acid (AA), 12mg of N,N'-methylenebisacrylamide (MBAA), stirred well to dissolve the solid matter, then dissolved 5mg of potassium persulfate in 1ml of deionized water and added to the previously prepared solution , stirred evenly to obtain a t...

Embodiment 2

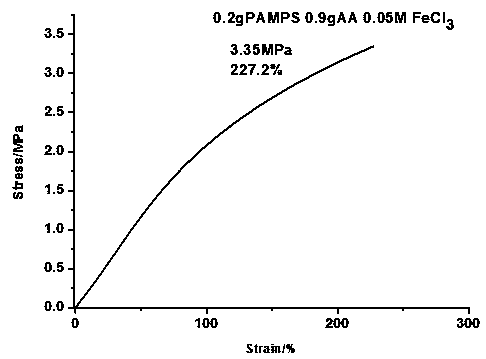

[0048] 1) Add 10g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) into 10ml of deionized water, stir evenly, heat up to 50°C, take 0.05g of ammonium persulfate and 0.025g of sodium bisulfite and dissolve in 1ml An initiator solution was prepared in water, and the above-mentioned initiator solution was added to the AMPS aqueous solution, and reacted for 20 hours. Most of the water was evaporated, and dried in a vacuum oven to constant weight to obtain PAMPS solid, which was ground into powder and set aside.

[0049] 2) Add 0.5g of polyvinyl alcohol (PVA) to 24ml of deionized water, heat to 95°C to dissolve, take 0.2g of PAMPS powder prepared in step 1) and add to the above solution, then add 5.33g of acrylamide (AM) , 0.9g of acrylic acid (AA), 12mg of N,N'-methylenebisacrylamide (MBAA), stirred well to dissolve the solid matter, then dissolved 5mg of potassium persulfate in 1ml of deionized water and added to the previously prepared solution , stirred evenly to obtain a t...

Embodiment 3

[0055] 1) Add 10g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) into 10ml of deionized water, stir evenly, heat up to 50°C, take 0.05g of ammonium persulfate and 0.025g of sodium bisulfite and dissolve in 1ml An initiator solution was prepared in water, and the above-mentioned initiator solution was added to the AMPS aqueous solution, and reacted for 20 hours. Most of the water was evaporated, and dried in a vacuum oven to constant weight to obtain PAMPS solid, which was ground into powder and set aside.

[0056] 2) Add 0.5g of polyvinyl alcohol (PVA) to 24ml of deionized water, heat to 95°C to dissolve, take 0.2g of PAMPS powder prepared in step 1) and add to the above solution, then add 5.33g of acrylamide (AM) , 0.9g of acrylic acid (AA), 12mg of N,N'-methylenebisacrylamide (MBAA), stirred well to dissolve the solid matter, then dissolved 5mg of potassium persulfate in 1ml of deionized water and added to the previously prepared solution , stirred evenly to obtain a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com