Preparation method of polyurethane/cellulose multifunctional shape memory high-molecular material

A polymer material and polyurethane technology, which is applied in the field of preparation of polyurethane/cellulose multifunctional shape memory polymer materials to achieve the effects of increasing elongation at break, improving shape memory function, and broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

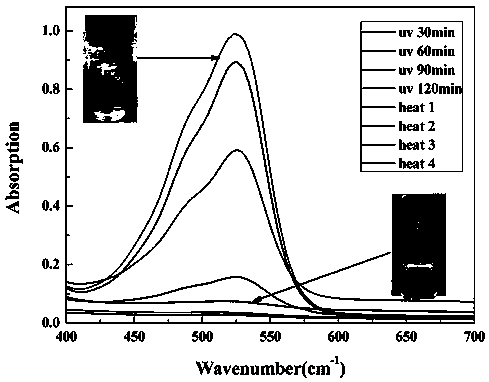

Image

Examples

example 1

[0029] (1) Homogeneous functionalization reaction of microcrystalline cellulose

[0030] First configure a new green composite solvent: accurately weigh 19g of 1-allyl, 3-methylimidazolium chloride salt ionic solvent, measure 10ml of absolute ethanol and 5ml of deionized water into a three-necked flask, and use ultrasonic After dispersing for 10 minutes, a clear and transparent composite solution was obtained. Add 1g of silane coupling agent, add dropwise acetic acid to adjust PH=4, then stir magnetically at 80°C for 1 hour to make the silane coupling agent hydrolyze. Then weigh 1g of microcrystalline cellulose and add it to the three-necked flask, continue to stir and react for 3 hours, cool to room temperature, use a Buchner funnel to filter and wash to obtain the filter residue, and wash so many times to remove the incompletely reacted silane coupling agent . Finally, the reacted microcrystalline cellulose was freeze-dried for 48 hours using a freeze dryer to obtain funct...

example 2

[0034] (1) Homogeneous functionalization reaction of microcrystalline cellulose

[0035] Carry out the functionalization reaction of microcrystalline cellulose according to Example 1, accurately weigh 19g of 1-allyl, 3-methylimidazolium chloride salt ionic solvent, measure 12.5ml of absolute ethanol and 5ml of deionized water into the three-necked flask In the process, a clear and transparent composite solution was obtained after ultrasonic dispersion for 10 min. Add 1 g of silane coupling agent, add dropwise acetic acid to adjust the pH to 4.5, and stir magnetically at 80°C for 1 hour to cause hydrolysis of the silane coupling agent. Then weigh 1g of microcrystalline cellulose and add it to the three-necked flask, continue to stir and react for 3 hours, cool to room temperature, use a Buchner funnel to filter and wash to obtain the filter residue, and wash so many times to remove the incompletely reacted silane coupling agent . Finally, the reacted microcrystalline cellulos...

example 3

[0039] (1) Homogeneous functionalization reaction of microcrystalline cellulose

[0040] Carry out the functionalization reaction of microcrystalline cellulose according to Example 1, accurately weigh 19g of 1-allyl, 3-methylimidazolium chloride salt ionic solvent, measure 15ml of absolute ethanol and 5ml of deionized water into a three-necked flask , a clear and transparent composite solution was obtained after ultrasonic dispersion for 10 min. Add 1 g of silane coupling agent, add dropwise acetic acid to adjust the pH to 5, and stir magnetically at 80°C for 1 hour to cause hydrolysis of the silane coupling agent. Then weigh 1g of microcrystalline cellulose and add it to the three-necked flask, continue to stir and react for 3 hours, cool to room temperature, use a Buchner funnel to filter and wash to obtain the filter residue, and wash so many times to remove the incompletely reacted silane coupling agent . Finally, after the reaction, the microcrystalline cellulose was free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com