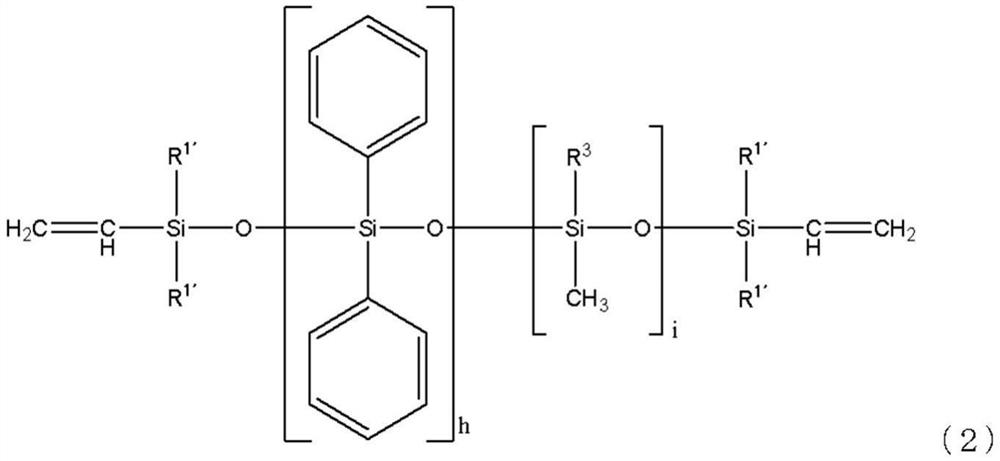

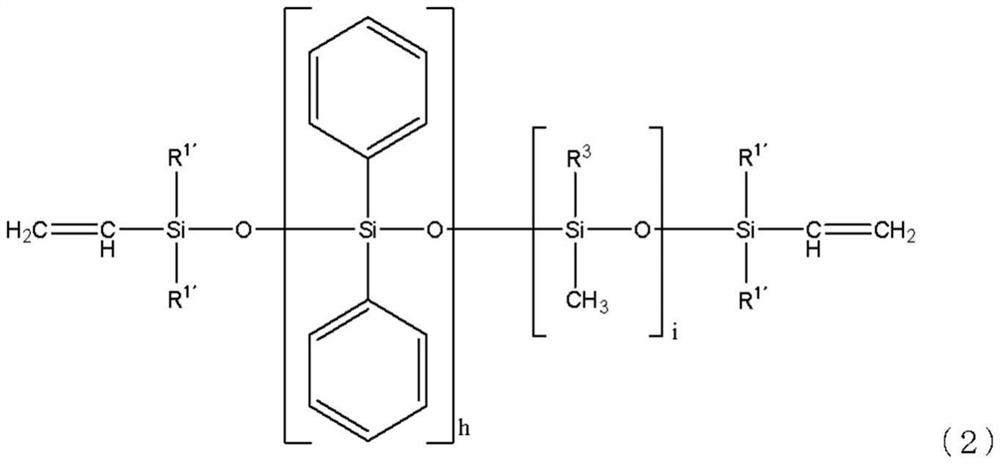

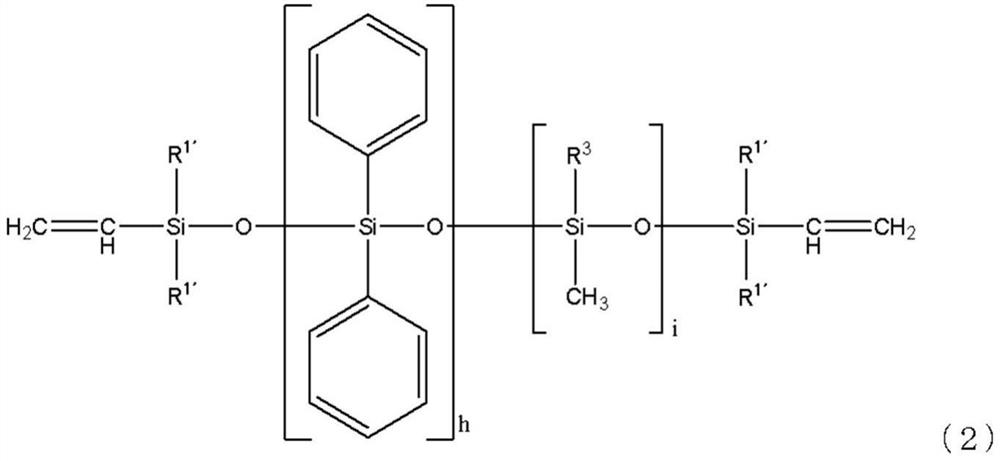

Addition-curable silicone composition, method for producing same, cured silicone product, and optical element

A silicone composition, addition-curing technology, applied in electrical components, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problem of insufficient heat discoloration resistance of phenyl silicone, temperature rise of sealing materials, LED Brightness reduction and other problems, to achieve the effect of less weight change, excellent heat resistance, and less discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0150] Hereinafter, the present invention will be specifically described using synthesis examples, examples, and comparative examples, but the present invention is not limited to these examples. In addition, in the following examples, the viscosity is the value at 25 degreeC measured using the rotational viscometer.

Synthetic example 1

[0152] 13 parts by mass (0.55 parts in terms of cerium) in turpentine (turpentine) solution of 2-ethylhexanoate containing cerium as the main component (rare earth element content is 6 mass %) and 2.7 parts by mass of titanium Tetra-n-butyl acid (titanium mass is 0.3 times the mass of cerium in the above-mentioned 2-ethylhexanoate) is fully mixed, and added to 130 parts by mass of ((CH 3 ) 3 SiO 1 / 2 ) 2 ((C 6 h 5 ) 2 SiO) 3.9 ((CH 3 ) 2 SiO) 8.6 In methylphenyl organopolysiloxane with a viscosity of 400 mPa·s, a yellow-white dispersion was obtained. While flowing a small amount of nitrogen gas into the dispersion liquid, heat it to let the turpentine flow out, and then heat it at 300°C for 1 hour. As a result, a uniform combination of dark brown and transparent polyorganometallic siloxane (C-1) was obtained. things. Analysis of the obtained polyorganometallic siloxane by ICP-OES (inductively coupled plasma optical emission spectrometry) revealed that the Ce content ...

Synthetic example 2

[0154] While stirring, 13 parts by mass (0.55 parts in terms of cerium) were added to 130 parts by mass of ((CH 3 ) 3 SiO 1 / 2 ) 2 ((C 6 h 5 ) 2 SiO) 3.9 ((CH 3 ) 2 SiO) 8.6 In methylphenyl organopolysiloxane with a viscosity of 400 mPa·s, a yellow-white dispersion was obtained. While flowing a small amount of nitrogen gas into the dispersion liquid, heat it to let the turpentine flow out, and then heat it at 300°C for 1 hour. As a result, a uniform combination of deep yellowish brown and transparent polyorganometallic siloxane (C-2) was obtained. thing. As a result of analyzing the obtained polyorganometallic siloxane by ICP-OES (inductively coupled plasma optical emission spectrometry), the Ce content was 3300 ppm. In addition, the viscosity of the polyorganometallic siloxane (C-2) was 220 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com