A kind of fermented mulberry wine and preparation method thereof

A fermented and mulberry wine technology, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, can solve the problems of backward brewing technology, susceptibility to acetic acid bacteria, and high cyanide content, and achieve wine Better body quality, unique taste and flavor, and soft-bodied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] (1) Screening and sterilization: Screening, cleaning of the mulberry, 10 ° C cold water, 125 mg / L sulfur dioxide solution is sterilized, all the fruit is broken; the mulberry is used to produce, the mulberry, fresh, no rot, pest fruit, and juice Rate ≥ 55%, total sugar 100 ~ 120 g / L, mulberry of total acid 3 to 5 g / L.

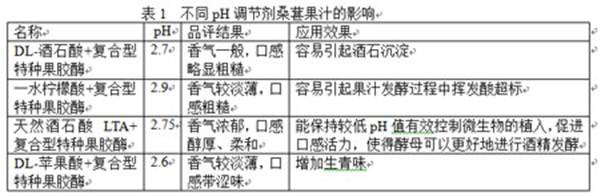

[0097] (2) Doubi component adjustment is carried out in synchronization with low temperature enzymatic hydrolysis: 2 g / l (final concentration) food grade natural tartaric acid LTA (Shanghai Jie Rabbit Industry & Trade Co., Ltd.) adjusted the pH of the mulberry juice 2.5 and 22 mg / l (final concentration) composite special pectinase RedStyle TM (France Raman Group, the following examples) 5.5 hours at the temperature of 13.7 ° C, the juice is 60%, resulting in an enzymatic hydrolysis product; maintaining a lower pH effective to control the implantation of the microorganism, so that the yeast can be better Alcohol fermentation and convenient later of ...

Embodiment 2

[0114] (1) Screening and sterilization: screened the mulberry, 10 ° C cold water, 125 mg / L sulfur dioxide solution is sterilized, all the fruit is broken; used for production of mulberry eight mature or more, fresh, no bad fruit, pest fruit, and juice The rate of ≥ 55%, total sugar 100 ~ 120 g / L, mulberry of total acid 3 to 5 g / L.

[0115] (2) Doubi component adjustment is carried out in synchronization with low temperature enzymatic hydrolysis: 2.5 g / l (final concentration) food grade natural tartaric acid LTA (Shanghai Jie Rabbit Industry & Trade Co., Ltd.) adjusted the pH of the mulberry juice in the crushing mulberry It was 2.75 and 23 mg / l (final concentration) composite special pectin enzyme (France Raman Group) at a temperature of 14.5 ° C for 61.5%, and the juice is 61.5% to obtain an enzymatic product.

[0116] (3) Controlling fermentation: Add 0.30 g / l (final concentration) wine yeast Enoferm BDX in the enzymatic hydrolysis product obtained by step (2) TM Yea...

Embodiment 3

[0128] (1) Screening and sterilization: screened the mulberry, 10 ° C cold water, 125 mg / L sulfur dioxide solution is sterilized, all the fruit is broken; used for production of mulberry eight mature or more, fresh, no bad fruit, pest fruit, and juice The rate of ≥ 55%, total sugar 100 ~ 120 g / L, mulberry of total acid 3 to 5 g / L.

[0129](2) Swash component adjustment is carried out in synchronization with low temperature enzymatic hydrolysis: 3 g / l (final concentration) food grade natural tartaric acid LTA (Shanghai Jie Rabbit Industry & Trade Co., Ltd.) adjusted the pH of the mulberry juice For 3.0 and 24 mg / l (final concentration) Composite special pectin enzyme (France Raman Group) at a temperature of 15.3 ° C, a juice is 62%, resulting in an enzymatic hydrolysis product; maintain a lower pH effective The implantation of the microorganisms allows yeast to better carry alcohol fermentation and facilitate the filtration of later liquor.

[0130] (3) Temperature fermen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com