Method for continuously producing nano tetrapod-like zinc oxide from secondary zinc slag

A four-needle zinc oxide and secondary zinc technology, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problem that the morphology of zinc oxide whiskers cannot be effectively controlled, which affects the efficient recycling of zinc resources, and nanoparticle Problems such as uneven composition, to achieve the effect of reducing equipment use and process flow, expanding raw material sources, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: utilize secondary zinc slag to continuously produce the method for nano-tetraacicular zinc oxide, concrete process steps are:

[0039] (1) Ingredients:

[0040] The mass percentage of the main chemical components in the secondary zinc slag is shown in Table 1. The secondary zinc slag is crushed, and then sieved into a diameter of less than or equal to 1cm through a sieve, and then weighed 100g;

[0041] Table 1 Main chemical composition of secondary zinc slag

[0042]

[0043] (2), melting and evaporative oxidation of raw materials:

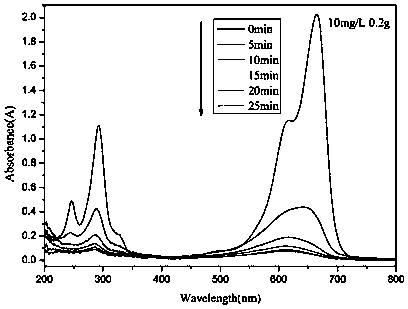

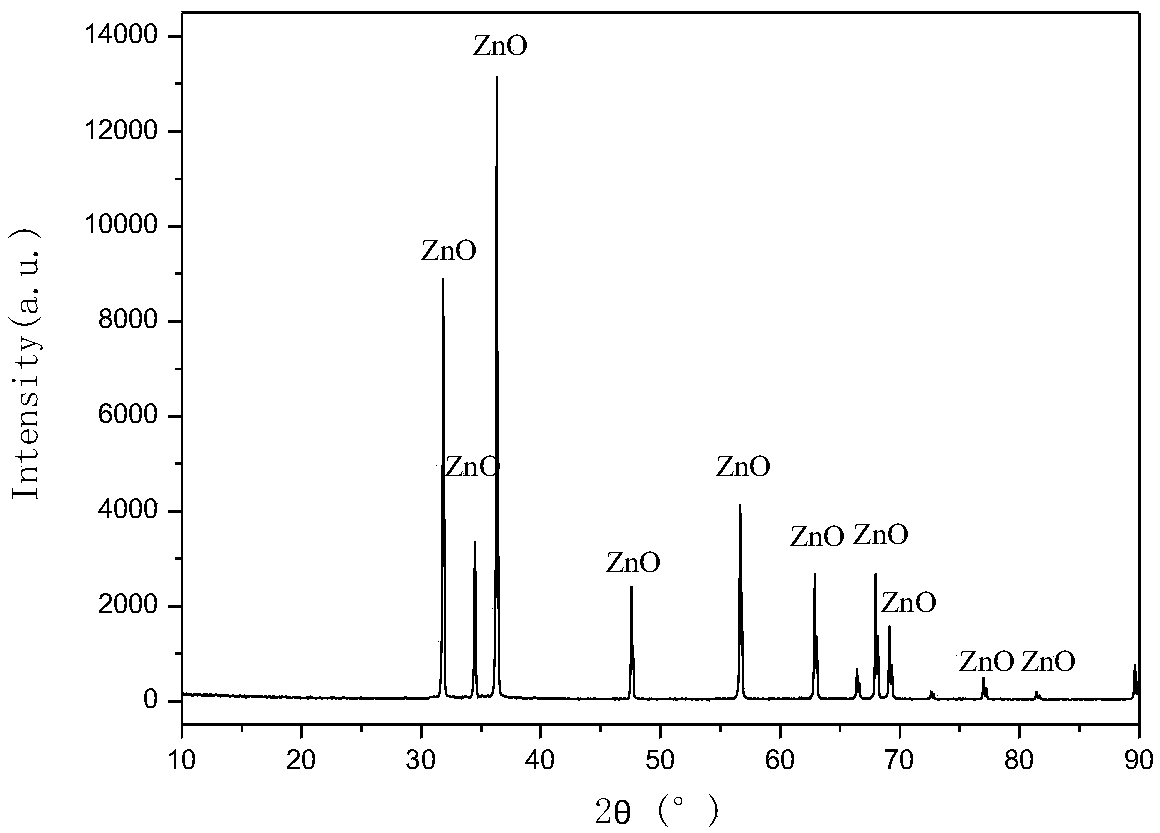

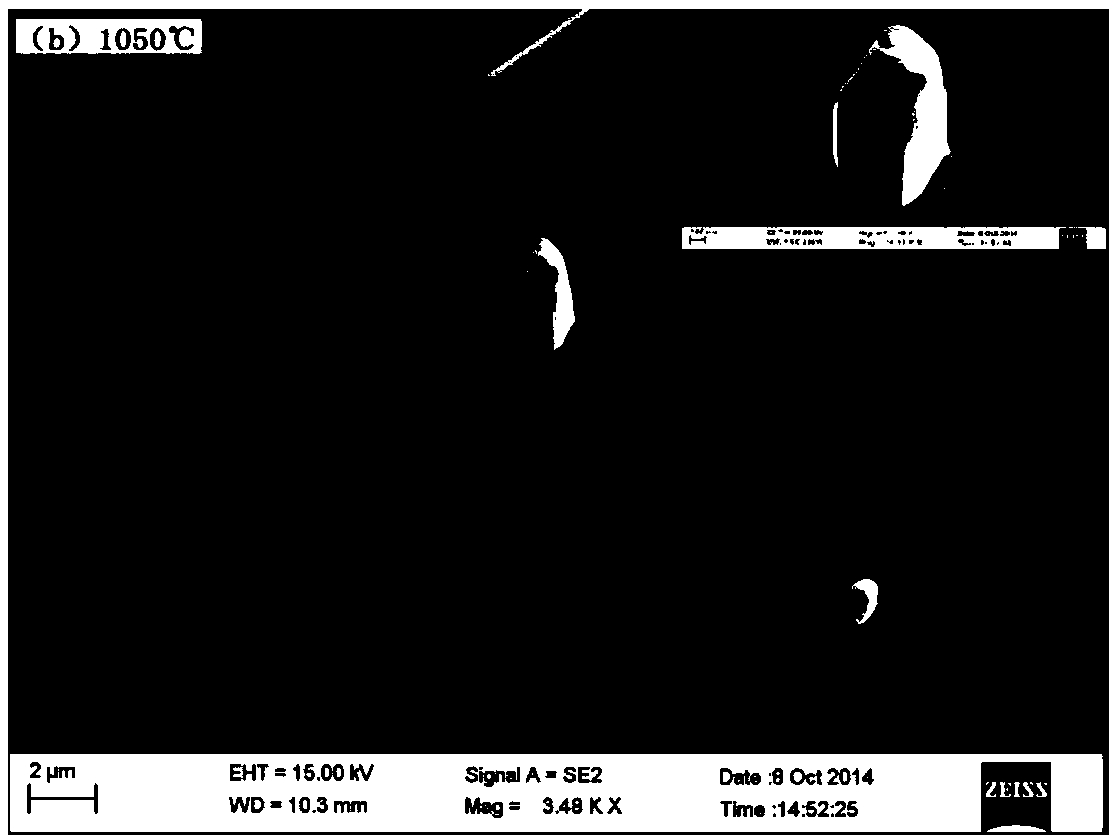

[0044] Put 100g of raw materials into a quartz crucible and place it at the center of the bottom of a closed crucible furnace. When heated to 700°C, keep the temperature constant for 20 minutes. The secondary zinc slag is in a molten state, and the slag liquid is layered; then raise the temperature to 1050°C. When no zinc vapor overflows from the mouth of the crucible furnace, it proves that Zn in the raw material has ev...

Embodiment 2

[0050] Embodiment 2: utilize secondary zinc slag to continuously produce the method for nano-tetraacicular zinc oxide, concrete process steps are:

[0051] (1) Ingredients:

[0052] The mass percentage of the main chemical components in the secondary zinc slag is shown in Table 2. The secondary zinc slag is crushed, then sieved into a diameter of less than or equal to 2cm by a sieve, and then weighed 500g;

[0053] Table 2 Main chemical composition of secondary zinc slag

[0054]

[0055] (2), melting and evaporative oxidation of raw materials:

[0056] Put the weighed 500g raw material into the quartz crucible, and place it at the center of the bottom of the closed crucible furnace. When heated to 700°C, keep the temperature for 20 minutes. The secondary zinc slag is in a molten state, and the slag liquid is layered; then the temperature is raised to 1100°C Constant temperature for 20 minutes; when no zinc vapor overflows from the mouth of the crucible furnace, it proves...

Embodiment 3

[0062] Embodiment 3: utilize secondary zinc slag to continuously produce the method for nano-tetraacicular zinc oxide, concrete process steps are:

[0063] (1) Ingredients:

[0064] The mass percentage of the main chemical components in the secondary zinc slag is shown in Table 3. The secondary zinc slag is crushed, and then sieved into a diameter of less than or equal to 3cm through a sieve, and then weighed 500g;

[0065] Table 3 Main chemical composition of secondary zinc slag

[0066]

[0067] (2), melting and evaporative oxidation of raw materials:

[0068] Put the weighed 500g raw material into the quartz crucible, and place it at the center of the bottom of the closed crucible furnace. When heated to 700°C, keep the temperature for 10 minutes. The secondary zinc slag is in a molten state, and the slag liquid is layered; then raise the temperature to 1150°C Constant temperature for 10 minutes; when there is no zinc vapor overflowing from the mouth of the crucible fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com