Surface-enhanced Raman substrate for large-area nanometer film structure and preparation method

A surface-enhanced Raman and large-area technology, applied in nanotechnology, Raman scattering, liquid chemical plating, etc., can solve the problems of high cost of SERS active substrates, difficulty breaking through the micron scale, and low hot spot density, and achieve The process can be adjusted, the experimental parameters are easy to control, and the effect of high density packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

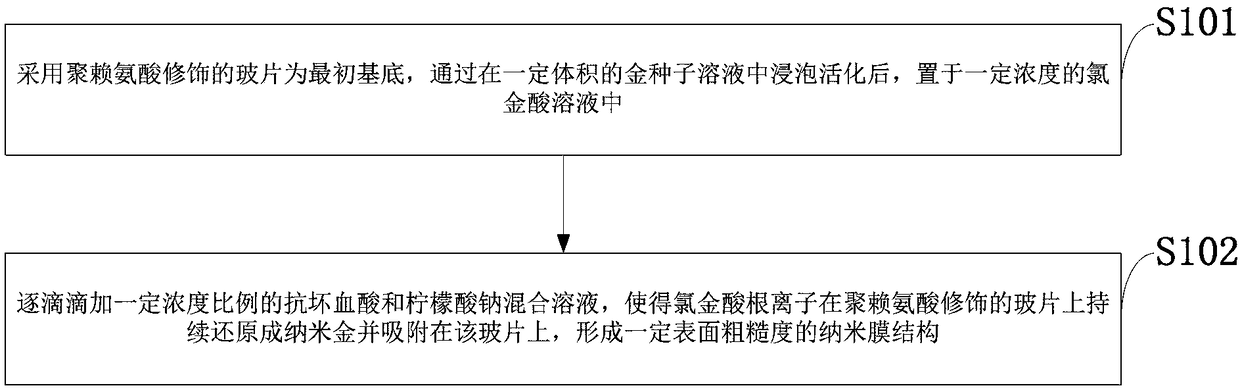

[0025] Such as figure 1 As shown, the preparation method of the surface-enhanced Raman substrate of the large-area nano-membrane structure provided by the embodiment of the present invention includes the following steps:

[0026] S101: The glass slide modified with polylysine is used as the initial substrate, activated by soaking in a certain volume of nano-gold seed solution, and then placed in a certain concentration of chloroauric acid solution;

[0027] S102: Add a mixed solution of ascorbic acid and sodium citrate at a certain concentration ratio drop by drop, so that the chloroaurate ion is continuously reduced to nano-gold on the polylysine-modified glass slide and adsorbed on the glass slide to form a certain surface roughness. nanomembrane structure.

Embodiment 1

[0030] 1) Cut common polylysine-modified slides into 2*2cm with a glass knife 2 The left and right small pieces are spared.

[0031] 2) In 10 mL of 0.025 mM chloroauric acid (HAuCl 4 ) solution, add 100 μL of 1% sodium citrate solution and stir evenly, then quickly add 500 μL of 10 mM sodium borohydride (NaBH 4 ) solution, after reacting for 30 minutes, add the above-mentioned small pieces of polylysine-modified slides, and soak them overnight in a refrigerator at 6°C to promote polylysine-modified amino groups (-NH 2 ) activation and hydrophilic properties.

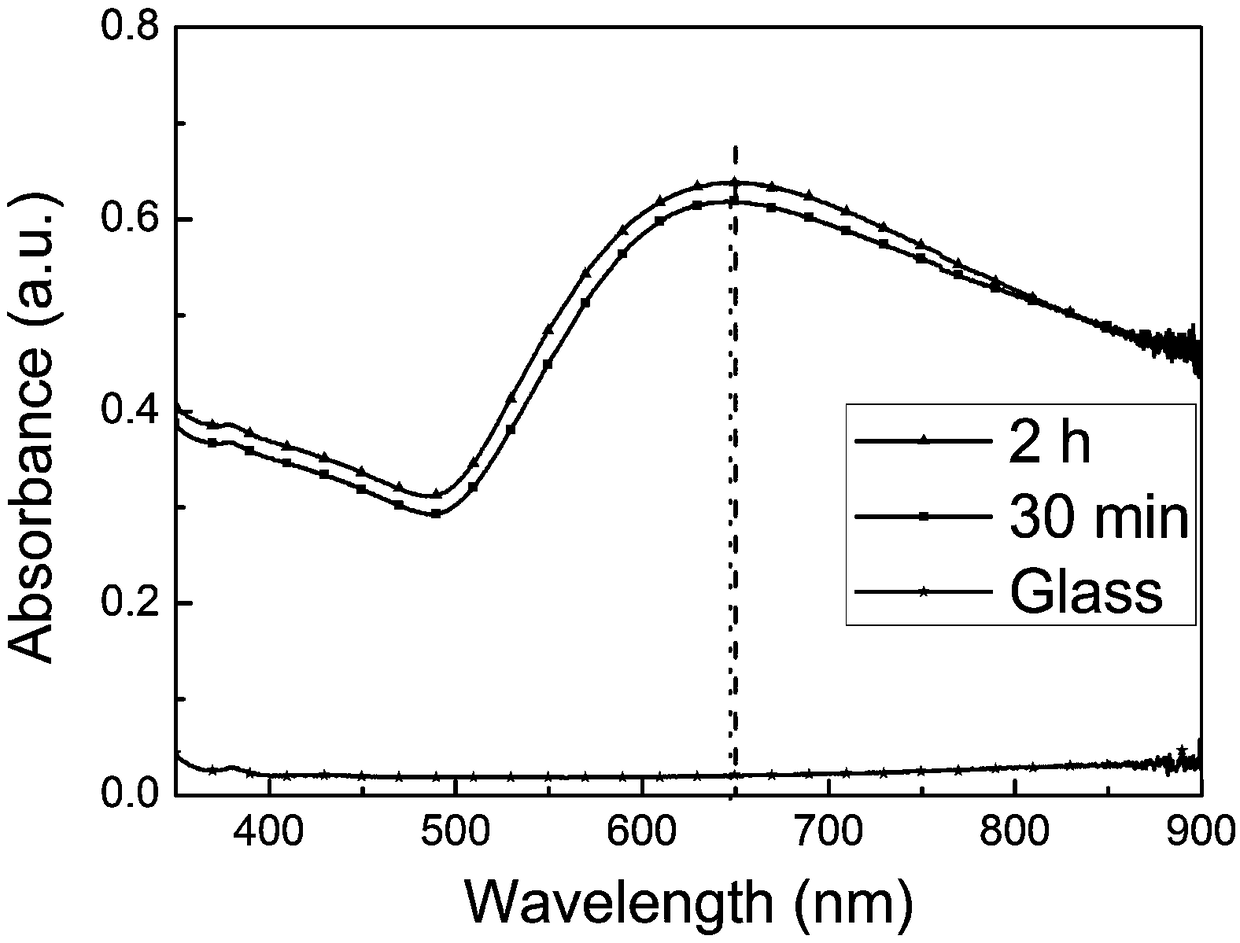

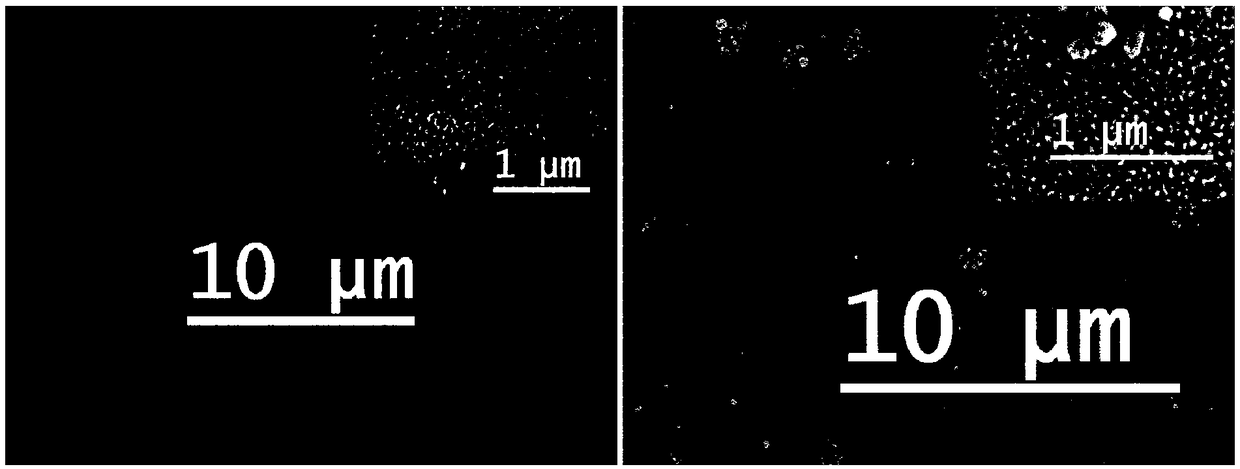

[0032] 3) Rinse the soaked slides with pure water and immerse them in 10mL of 10 -4 M's chloroauric acid solution. At the same time, a mixed solution of 10 mL of ascorbic acid and sodium citrate was added dropwise with a microsyringe pump, the dropping rate of the microsyringe pump was 20 mL / h, and the concentrations of ascorbic acid and sodium citrate were 0.05% and 0.025%, respectively. After the completion of the...

Embodiment 2

[0035] 1) Cut common polylysine-modified slides into 2*2cm with a glass knife 2 The left and right small pieces are spared.

[0036] 2) In 10 mL of 0.025 mM chloroauric acid (HAuCl 4 ) solution, add 100 μL of 1% sodium citrate solution and stir evenly, then quickly add 500 μL of 10 mM sodium borohydride (NaBH 4 ) solution, after reacting for 30 minutes, add the above-mentioned small pieces of polylysine-modified slides, and soak them overnight in a refrigerator at 6°C to promote polylysine-modified amino groups (-NH 2 ) activation and hydrophilic properties.

[0037] 3) Rinse the soaked slides with pure water and immerse them in 10mL of 10-4 M's chloroauric acid solution. At the same time, a mixed solution of 10 mL of ascorbic acid and sodium citrate was added dropwise with a micro-injection pump, the drip rate of the micro-injection pump was 20 mL / h, and the concentrations of ascorbic acid and sodium citrate were 0.05% and 0.025%, respectively. After the completion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com