Three-dimensional porous copper-silicon-carbon composite integrated electrode and preparation method thereof

A three-dimensional porous, carbon composite technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of destruction, capacity decline, active material crushing and pulverized electrode structure, so as to prevent pulverization and crushing and improve stability , the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of the copper-silicon-carbon integrated electrode specifically provided in this example includes the following steps:

[0020] 1) Preparation of copper-silicon alloy: dry copper powder and silicon powder in a vacuum drying oven in advance, and dry at 60° C. for 12 hours. Weigh copper and silicon according to the volume ratio of 3:1, weigh 23g and 2g of copper and silicon respectively, and pour them into the ball milling tank, then weigh 250g of ball milling beads according to the material ratio of 10:1 and pour them into the ball milling tank, and pour an appropriate amount Alcohol is used to submerge the ball milling beads, and then the copper-silicon alloy can be obtained after ball milling on a ball mill for 50 hours.

[0021] 2) Preparation of three-dimensional porous copper-silicon film precursor: place the copper-silicon alloy prepared in step 1) in a vacuum drying oven at 60°C for 12 hours, then weigh 1 g of copper-silicon alloy powder and ...

Embodiment 2

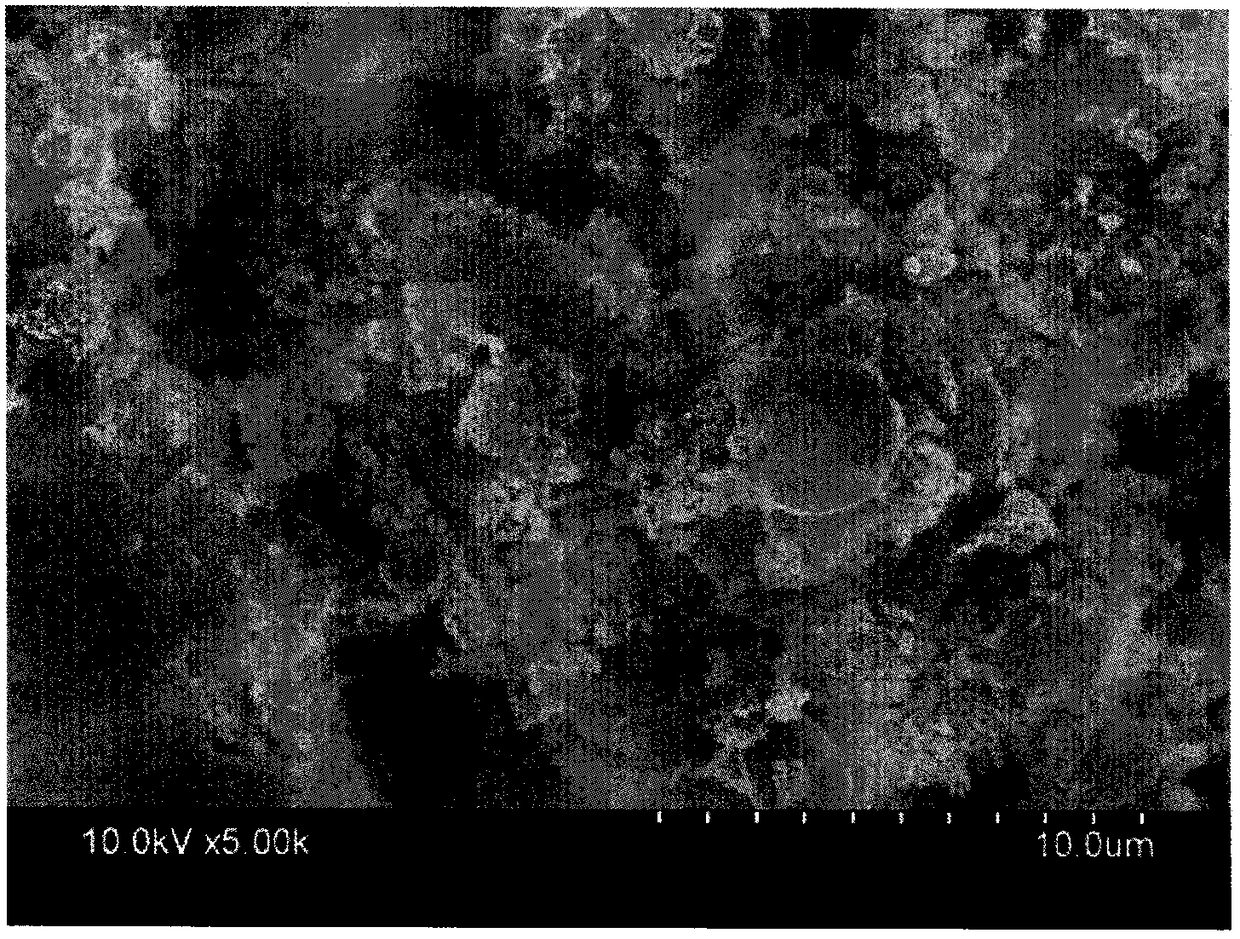

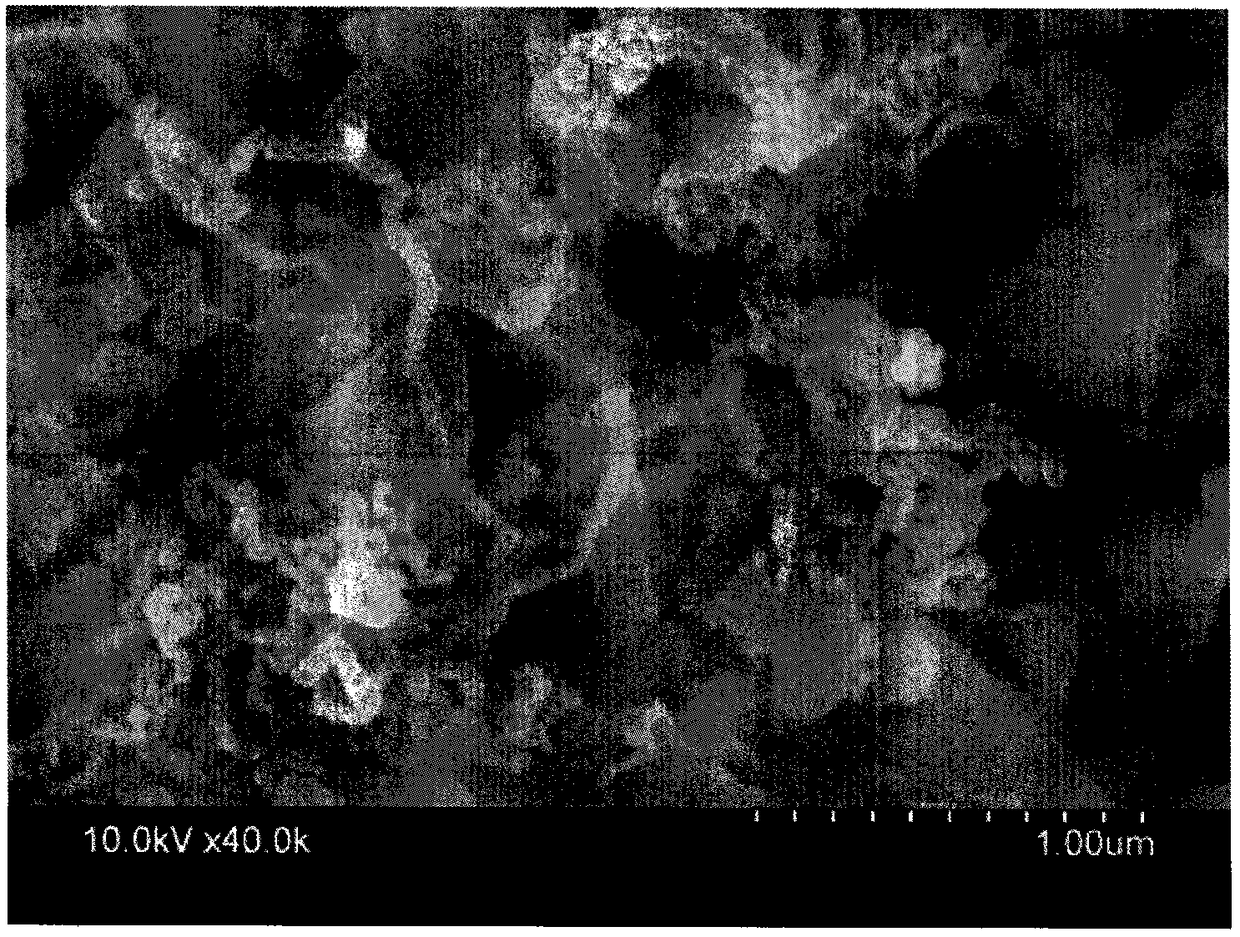

[0026] The difference from Example 1 is that in the above step 4), the prepared three-dimensional porous copper-silicon film is placed in a crucible, and after the temperature rises to 600°C at a rate of 10°C / min under an argon atmosphere, and at the highest The temperature was kept for 30 minutes. When the temperature reached 600°C, 6sccm acetylene and 100sccm hydrogen were introduced, and the furnace was removed after 10 minutes to obtain a three-dimensional porous copper-silicon-carbon composite integrated electrode. Compared with Example 1, the gas flow rate of control acetylene is constant while increasing the heat preservation time when feeding gas so as to control the growth of carbon nanotubes, as image 3 The scanning electron microscope image of the copper-silicon-carbon integrated electrode shown, it can be seen from the image that there are many carbon nanotubes formed on the surface, the length is relatively uniform, and the growth is in the form of bundles.

Embodiment 3

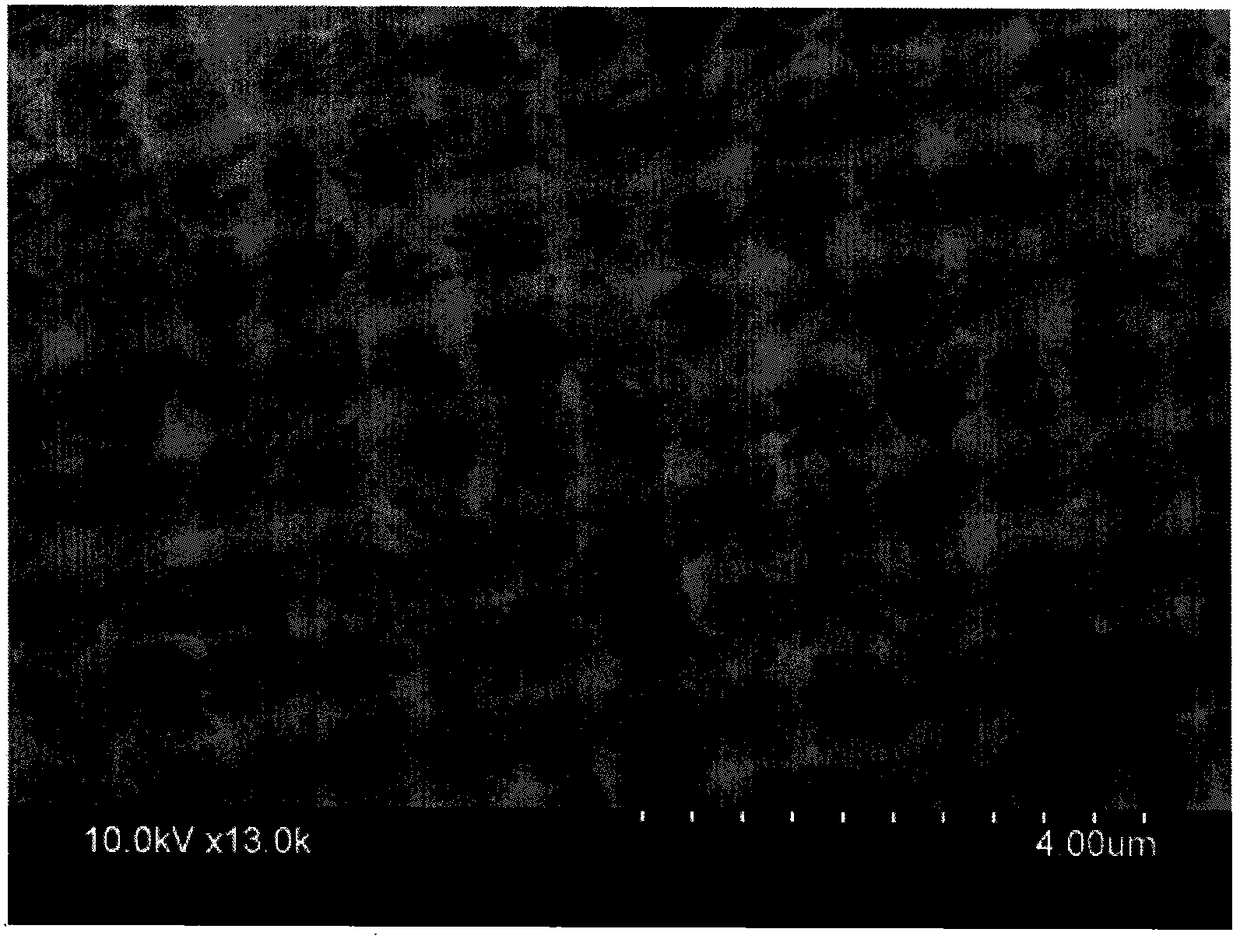

[0028] The difference from Example 1 is that in the above step 4), the prepared three-dimensional porous copper-silicon film is placed in a crucible, and after the temperature rises to 600°C at a rate of 10°C / min under an argon atmosphere, and at the highest The temperature was kept for 30 minutes. When the temperature reached 600°C, 6sccm acetylene and 100sccm hydrogen were introduced, and the furnace was removed after 15 minutes to obtain a three-dimensional porous copper-silicon-carbon composite integrated electrode. Compared with embodiment 1, 2, continue to keep the gas flow rate of acetylene constant, continue to increase the heat preservation time when feeding gas to control the growth of carbon nanotubes, as Figure 4 The scanning electron microscope image of the copper-silicon-carbon integrated electrode is shown. It can be seen from the figure that a large number of carbon nanotubes are formed on its surface, and the generated carbon nanotubes are in a three-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com