Preparation method of multifunctional gel polymer electrolyte with gradient barium titanate content

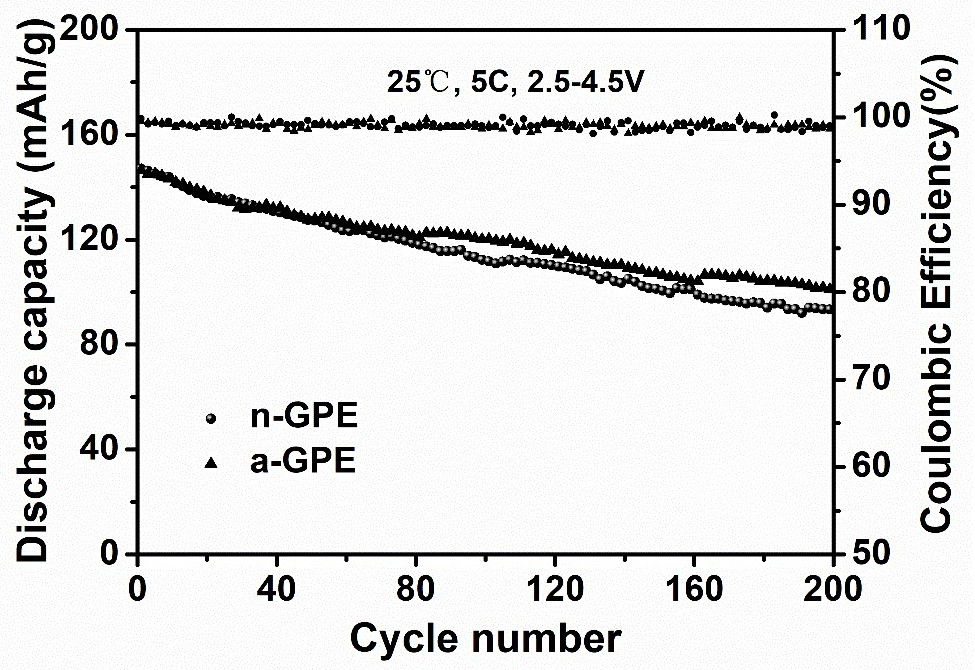

A technology of gel polymer and gradient barium titanate, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of interface instability, poor temperature resistance of pure polymer fiber membranes, etc., to ensure ionic conductivity Efficiency and mechanical strength, the effect of achieving long-term cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Component I is polyvinylidene fluoride-hexafluoropropylene with a molecular weight of 450,000 g / mol (Mw), produced by Aldrich Chemical Company of the United States. The dielectric constant of the polyvinylidene fluoride-hexafluoropropylene is greater than 6, and it has film-forming sex.

[0032] Component II is barium titanate, produced by Aldrich Chemical Company of the United States.

[0033] Component III is a mixed solvent of N,N-dimethylformamide and acetone, with a purity of ≥99%, produced by Beijing Tongguang Fine Chemical Co., Ltd., wherein the mixing mass ratio of N,N-dimethylformamide and acetone is is 0.7.

[0034] Add component II with a mass ratio of 0wt%, 8wt%, and 15wt% to component III, disperse with ultrasonic assistance for 2 hours, and after component II is evenly distributed in component III, add 20wt% component I, Heating and stirring at a temperature of 50-60° C. for 6-8 hours to obtain spinning solutions with component II contents of 0 wt %, 8 w...

Embodiment 2

[0039] Component I is polyvinylidene fluoride-hexafluoropropylene with a molecular weight of 450,000 g / mol (Mw), produced by Aldrich Chemical Company of the United States. The dielectric constant of the polyvinylidene fluoride-hexafluoropropylene is greater than 6, and it has film-forming sex.

[0040] Component II is barium titanate, produced by Aldrich Chemical Company of the United States.

[0041] Component III is a mixed solvent of N,N-dimethylformamide and acetone with a purity of ≥99%, produced by Beijing Tongguang Fine Chemical Co., Ltd. The mixing mass ratio of N,N-dimethylformamide and acetone is 0.8 .

[0042] Add component II with a mass ratio of 3wt%, 10wt%, and 17wt% to component III, ultrasonically disperse for 1 h to make component II evenly distributed in component III, add 15wt% component I, and Heat and stir at 50-60°C for 6-8 hours to obtain spinning solutions with component II contents of 3wt%, 10wt%, and 17wt%.

[0043] Under the conditions of a voltag...

Embodiment 3

[0047] Component I is polyvinylidene fluoride-hexafluoropropylene with a molecular weight of 500,000 g / mol (Mw), produced by Aldrich Chemical Company of the United States. The dielectric constant of the polyvinylidene fluoride-hexafluoropropylene is greater than 6, and it has film-forming properties sex. Component II is barium titanate, produced by Aldrich Chemical Company of the United States. Component III is a mixed solvent of N,N-dimethylformamide and acetone, with a purity of ≥99%, produced by Beijing Tongguang Fine Chemical Company. Component II with a mass ratio of 0wt%, 8wt%, and 15wt% was added to component III, wherein the mixing mass ratio of N,N-dimethylformamide and acetone in component III was 1.0. After ultrasonic dispersion treatment makes component II evenly distributed in component III, add 16wt% component I, and heat and stir at 50~60°C for 6~8h.

[0048] Under the conditions of a voltage of 23kV and a flow rate of 1mL / h, spinning solutions with mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com