A kind of anti-corrosion and wear-resistant carbonized silica gel and its equipment repair method

A technology of wear-resistant carbonized silica gel and repair method, which is applied in mechanical equipment, pipe components, pipes/pipe joints/pipe fittings, etc., and can solve the problems of low reliability and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

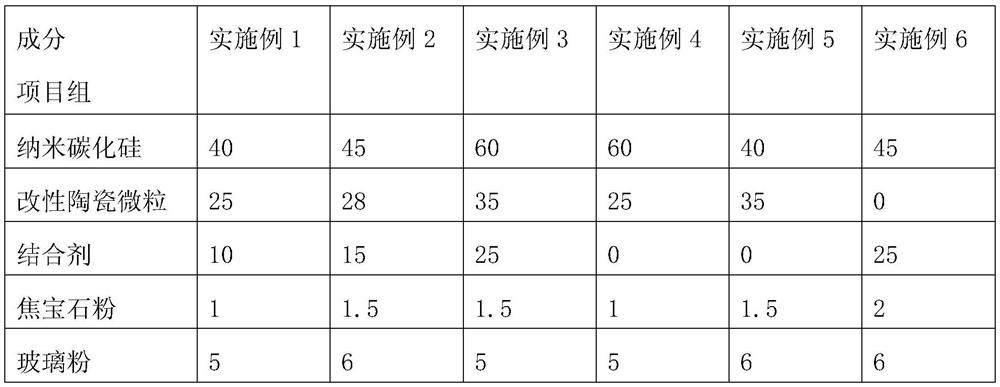

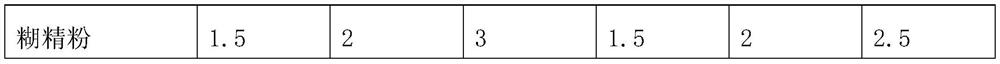

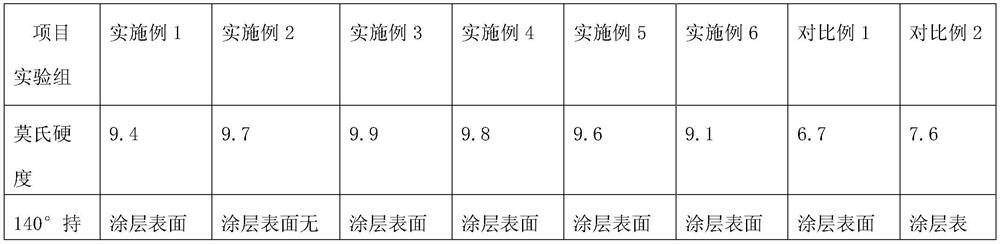

Embodiment 1

[0031] The invention provides an anti-corrosion and wear-resistant carbonized silica gel, which comprises the following raw materials in parts by weight:

[0032] 40 parts of nano silicon carbide; 25 parts of modified ceramic particles; 10 parts of binder; 1 part of coke powder; 5 parts of glass powder; 1.5 parts of dextrin powder.

[0033] Wherein, the modified ceramic particles in this embodiment are prepared by the following method:

[0034] Step S1, calcining ceramic particles with a particle size of ≤0.344mm at a temperature of 650-780°C for 2-3 hours, cooling to room temperature after calcining, and grinding the ceramic particles to 80-130 mesh to obtain ceramic fine powder;

[0035] Then, add isocyanate into the ceramic micropowder and soak for 1-2.5h, and stir evenly at 85-105°C to obtain the modified ceramic micropowder.

[0036] Preferably, the ceramic particles in step S1 are one or more mixtures of titanium nitride ceramics, alumina ceramics, boron carbide ceramic...

Embodiment 2

[0039] The invention provides an anti-corrosion and wear-resistant carbonized silica gel, which comprises the following raw materials in parts by weight:

[0040] 45 parts of nano silicon carbide; 28 parts of modified ceramic particles; 15 parts of binder; 1.5 parts of coke powder; 6 parts of glass powder; 2 parts of dextrin powder.

[0041] Stir and mix the above materials according to the proportion to make a mixed powder, add water at a temperature of 45°C-65°C, stir and mix evenly to make an anti-corrosion and wear-resistant carbonized silica gel.

[0042] Wherein, the modified ceramic particles in this embodiment are prepared by the following method:

[0043] Step S1, calcining ceramic particles with a particle size of ≤0.344mm at a temperature of 650-780°C for 2-3 hours, cooling to room temperature after calcining, and grinding the ceramic particles to 80-130 mesh to obtain ceramic fine powder;

[0044] Then, add isocyanate into the ceramic micropowder and soak for 1-2....

Embodiment 3

[0048] The invention provides an anti-corrosion and wear-resistant carbonized silica gel, which comprises the following raw materials in parts by weight:

[0049] 60 parts of nano-silicon carbide; 35 parts of modified ceramic particles; 25 parts of binder; 1.5 parts of coke powder; 5 parts of glass powder; 3 parts of dextrin powder.

[0050] Wherein, the modified ceramic particles in this embodiment are prepared by the following method:

[0051] Step S1, calcining ceramic particles with a particle size of ≤0.344mm at a temperature of 650-780°C for 2-3 hours, cooling to room temperature after calcining, and grinding the ceramic particles to 80-130 mesh to obtain ceramic fine powder;

[0052]Then, add isocyanate into the ceramic micropowder and soak for 1-2.5h, and stir evenly at 85-105°C to obtain the modified ceramic micropowder.

[0053] Preferably, the ceramic particles in step S1 are one or more mixtures of titanium nitride ceramics, alumina ceramics, boron carbide ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com