Resource utilization method of agricultural and forestry wastes

A technology for recycling agricultural and forestry waste, applied in the field of environmental protection, can solve problems such as unclear market prospects, lack of economic feasibility, and complicated process of resource-based products, so as to improve added value and market application prospects, and simplify marketing work , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

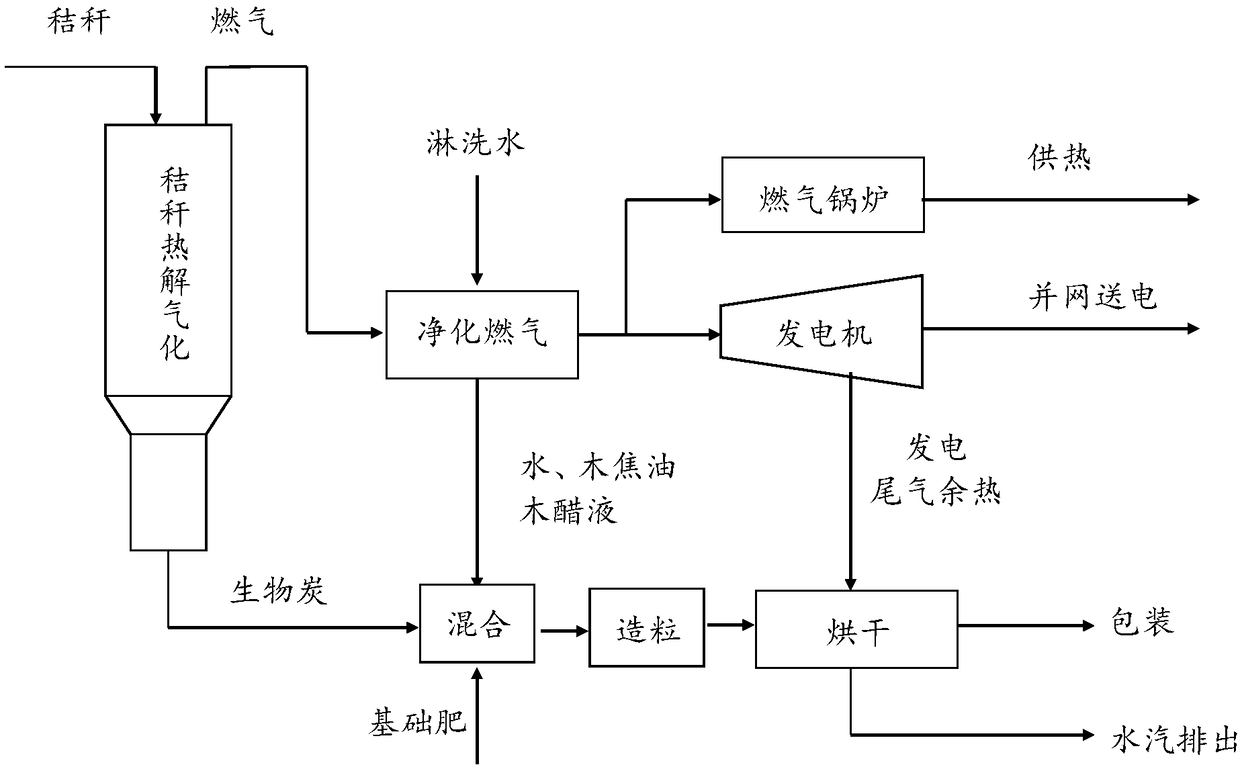

[0034] This embodiment provides a figure 1 The resource utilization method of agricultural and forestry waste in the process shown, the specific process includes:

[0035] Crush wheat straw into particles with a length of about 4 cm, and perform pyrolysis and gasification in a straw pyrolysis gasification furnace (gasification pyrolysis temperature 500°C, oxygen volume content ≤ 5%) to obtain gas to be purified and biochar; The gas to be purified is rinsed with water to obtain purified gas and leached waste liquid; part of the purified gas is sent to a gas boiler for heating, and the other part is sent to a gas generator to generate electricity. Grid-connected power transmission; after mixing the basic fertilizer, the biochar and the leaching waste liquid in proportion, mechanically extrude and granulate, then use the waste heat of the power generation tail gas to dry, and pack after cooling to obtain the carbon-based fertilizer granule product.

[0036] In the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com