Plug pin type titanium alloy panel friction stir spot welding method

A technology of friction stir and titanium alloy, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of "effective keyhole removal, little application research, and immaturity" and achieve convenient atmosphere protection device, Small amount of thinning and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

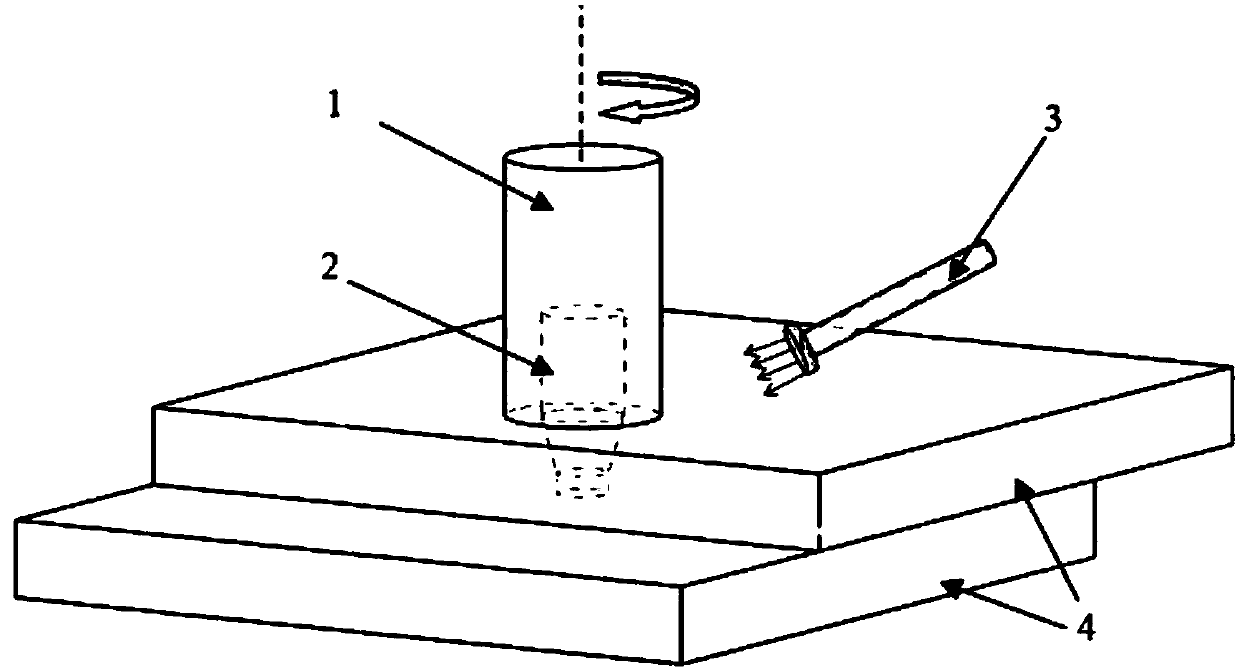

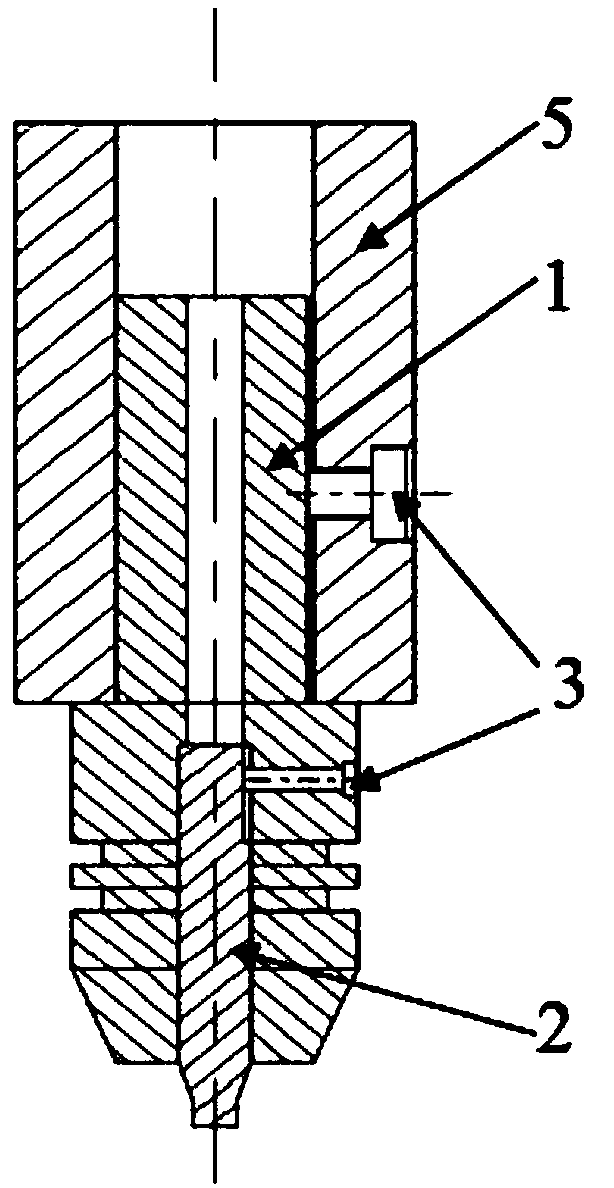

[0018] The implementation process of the plug-pin type titanium alloy friction stir spot welding method is as follows:

[0019] (1) Fix and position the titanium alloy plate 4 to be spot welded on the welding machine to ensure that there is no bulging and movement between the upper and lower base metals during the welding process, and move the position of the welding machine table to determine the welding point for spot welding Use a conical drill bit to process a concave conical preset hole 7 on the welding point of the base metal, and use compressed air to blow and clean the preset hole 7 to make the surface free of debris and oil, so as to ensure the surface of the upper plate in the welding area The thickness is H, the upper opening diameter of the concave taper hole is 1H, and the depth is usually 1.9H, usually a concave blind hole;

[0020] (2) Based on the inner diameter and depth of the preset hole 7, prepare and select a matching plug 2 according to the principle of f...

Embodiment 2

[0028] The implementation process of the plug-pin type titanium alloy friction stir spot welding method is as follows:

[0029] (1) Fix and position the titanium alloy plate 4 to be spot welded on the welding machine to ensure that there is no bulging and movement between the upper and lower base metals during the welding process, and move the position of the welding machine table to determine the welding point for spot welding Use a conical drill bit to process a concave conical preset hole 7 on the welding point of the base metal, and use compressed air to blow and clean the preset hole 7 to make the surface free of debris and oil, so as to ensure the surface of the upper plate in the welding area The thickness is H, the upper opening diameter of the concave taper hole is 3H, the depth is usually 3H, and it is usually a concave blind hole;

[0030] (2) Based on the inner diameter and depth of the preset hole 7, prepare and select a matching plug 2 according to the principle ...

Embodiment 3

[0038] The implementation process of the plug-pin type titanium alloy friction stir spot welding method is as follows:

[0039] (1) Fix and position the titanium alloy plate 4 to be spot welded on the welding machine to ensure that there is no bulging and movement between the upper and lower base metals during the welding process, and move the position of the welding machine table to determine the welding point for spot welding Use a conical drill bit to process a concave conical preset hole 7 on the welding point of the base metal, and use compressed air to blow and clean the preset hole 7 to make the surface free of debris and oil, so as to ensure the surface of the upper plate in the welding area The thickness is H, the upper opening diameter of the concave taper hole is 1.5H, and the depth is usually 2.5H, usually a concave blind hole;

[0040] (2) Based on the inner diameter and depth of the preset hole 7, prepare and select a matching plug 2 according to the principle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com