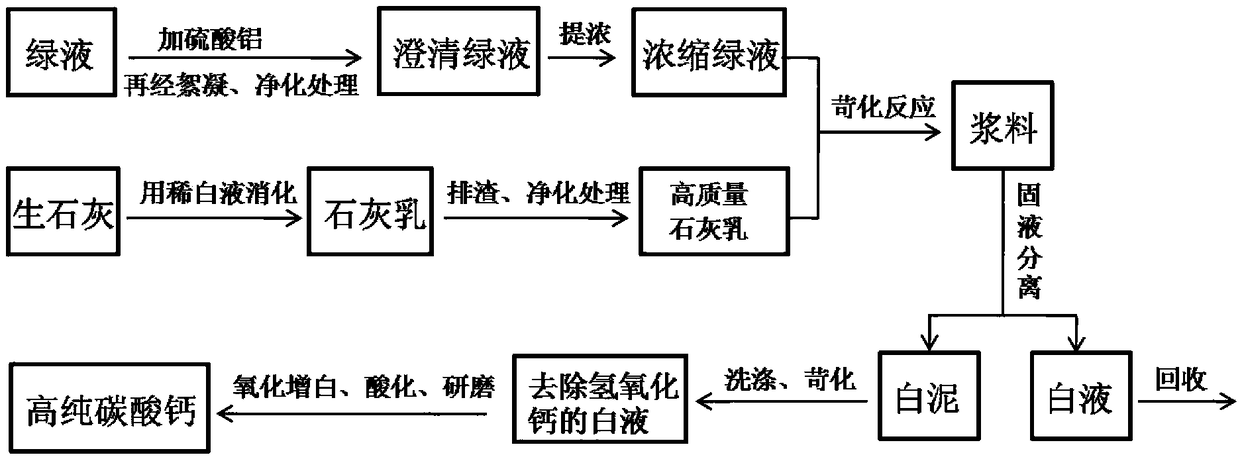

Method for refining high-purity calcium carbonate from green liquor by causticization

A technology of calcium carbonate and green liquor, applied in the direction of calcium carbonate/strontium/barium, regeneration of pulping liquid, addition of inorganic compounds, etc. problems, to reduce digestion time, facilitate reuse, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

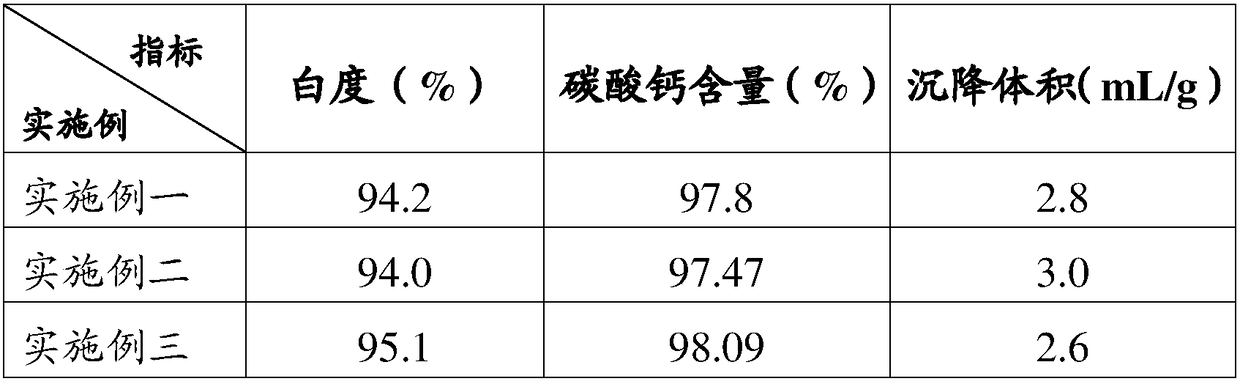

Examples

Embodiment 1

[0061] A kind of kraft bamboo wood mixed pulping green liquor refining calcium carbonate method of the present invention comprises the following steps:

[0062] (1) Desiliconization of green liquor: Add 20 mL of aluminum sulfate with a mass fraction of 10% to 1 L of green liquor, and stir to convert the silicate in the green liquor into aluminosilicate precipitation;

[0063] (2) Green liquor flocculation: add 4g of crushed quicklime to the green liquor, stir, add 10mg of anionic polyacrylamide, continue to stir, the stirring speed is first fast and then slow, and stand for 20min;

[0064] (3) Green liquor purification: Add 20 mL of 10% triethanolamine to the flocculated green liquor, stir gently, then add 5 mL of 10% disodium edetate, stir, and let stand for 10 minutes;

[0065] (4) Green liquor filtration: filter the flocculated and purified green liquor to obtain clarified green liquor;

[0066] (5) Concentration of green liquor: main components of green liquor after treat...

Embodiment 2

[0081] (1) Desiliconization of green liquor: Add 20 mL of aluminum sulfate with a mass fraction of 10% to 1 L of green liquor, and stir to convert the silicate in the green liquor into aluminosilicate precipitation;

[0082] (2) Green liquor flocculation: add 4g of crushed quicklime to the green liquor, stir, add 10mg of anionic polyacrylamide, continue to stir, the stirring speed is first fast and then slow, and stand for 20min;

[0083] (3) Green liquor purification: Add 20 mL of 10% triethanolamine to the flocculated green liquor, stir gently, then add 5 mL of 10% disodium edetate, stir, and let stand for 10 minutes;

[0084] (4) Green liquor filtration: filter the flocculated and purified green liquor to obtain clarified green liquor;

[0085] (5) Concentration of green liquor: main components of green liquor after treatment: 11.6g of NaOH, 15.5g of NaOH 2 S, 84.8g of Na 2 CO 3 , the total alkali content is 111.9g (both in Na 2 O meter), the green liquor heating and co...

Embodiment 3

[0100] (1) Desiliconization of green liquor: Add 20 mL of aluminum sulfate with a mass fraction of 10% to 1 L of green liquor, and stir to convert the silicate in the green liquor into aluminosilicate precipitation;

[0101] (2) Green liquor flocculation: add 4g of crushed quicklime to the green liquor, stir, add 10mg of anionic polyacrylamide, continue to stir, the stirring speed is first fast and then slow, and stand for 20min;

[0102] (3) Green liquor purification: Add 20 mL of 10% triethanolamine to the flocculated green liquor, stir gently, then add 5 mL of 10% disodium edetate, stir, and let stand for 10 minutes;

[0103] (4) Green liquor filtration: filter the flocculated and purified green liquor to obtain clarified green liquor;

[0104] (5) Concentration of green liquor: main components of green liquor after treatment: 14.9g of NaOH, 16.7g of NaOH 2 S, 96.6g of Na 2 CO 3 , the total alkali content is 128.2g (both in Na 2 O meter), the green liquor heating and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sedimentation volume | aaaaa | aaaaa |

| Sedimentation volume | aaaaa | aaaaa |

| Sedimentation volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com