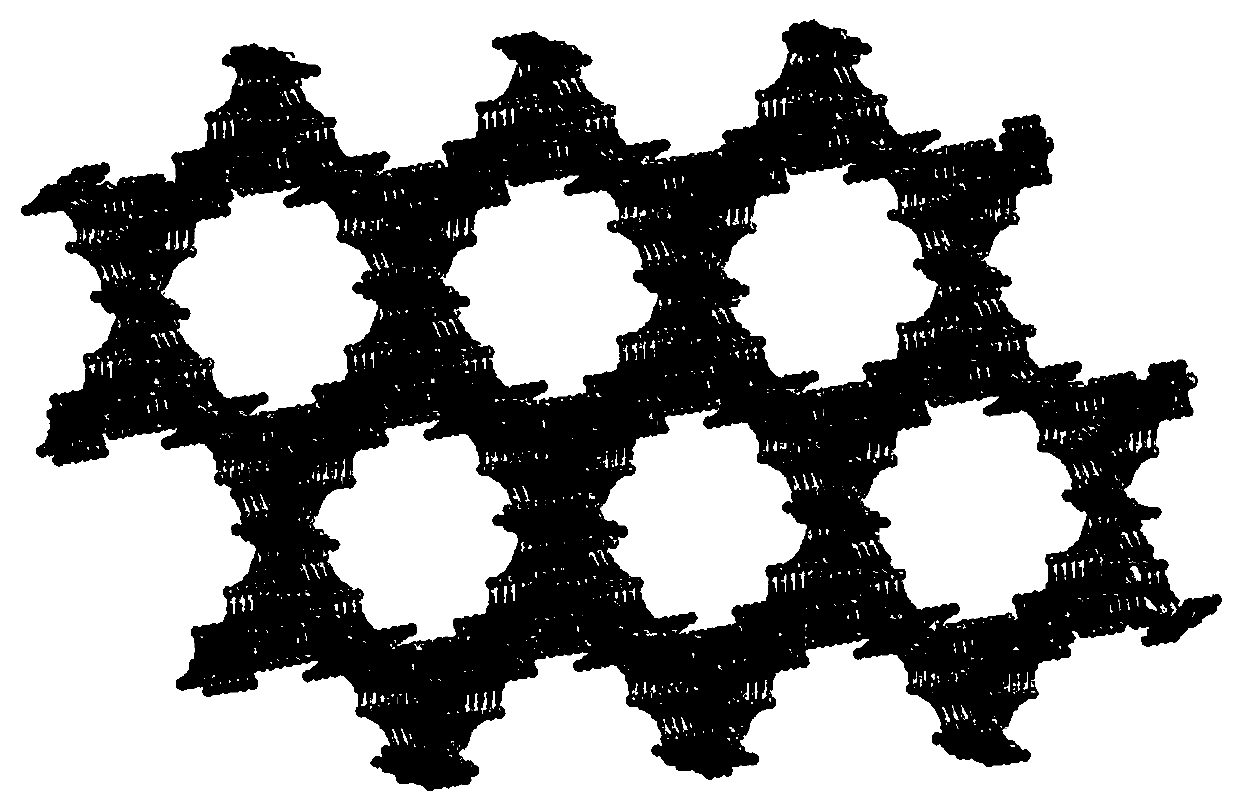

A kind of preparation method of copper complex and its application

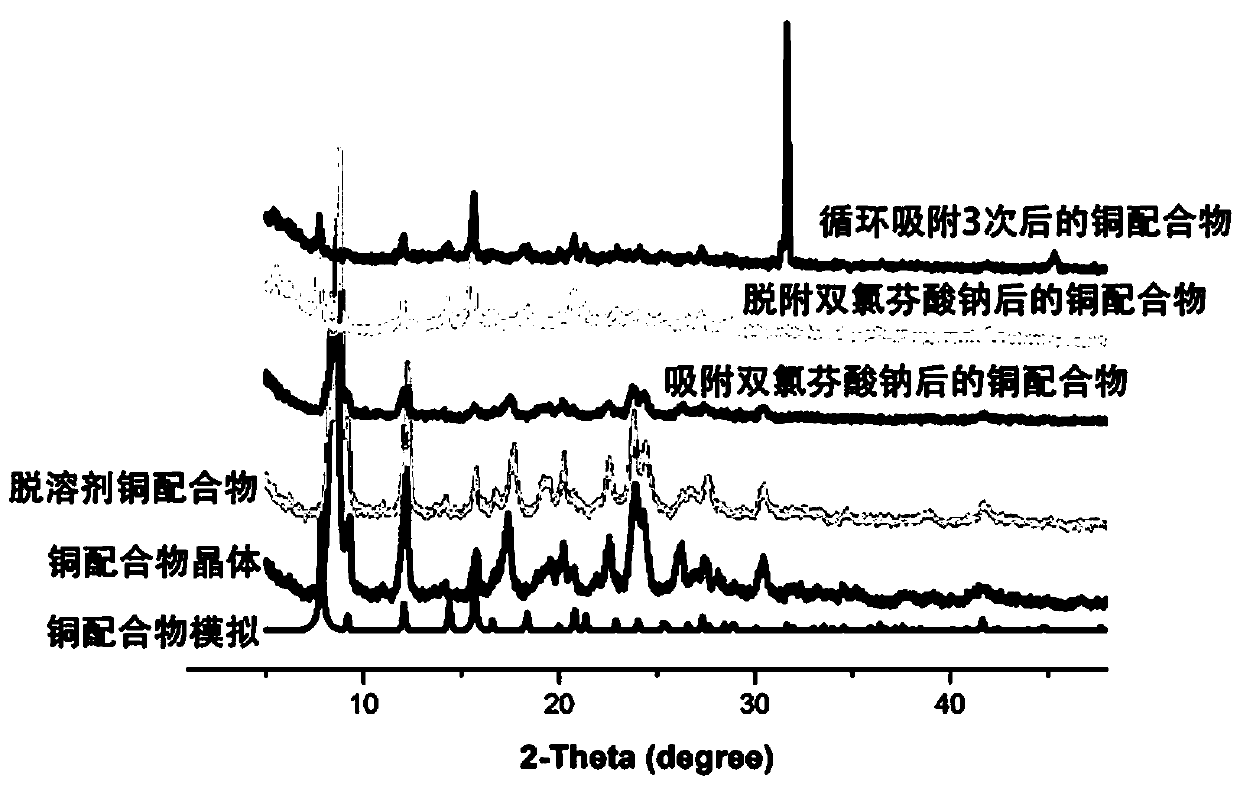

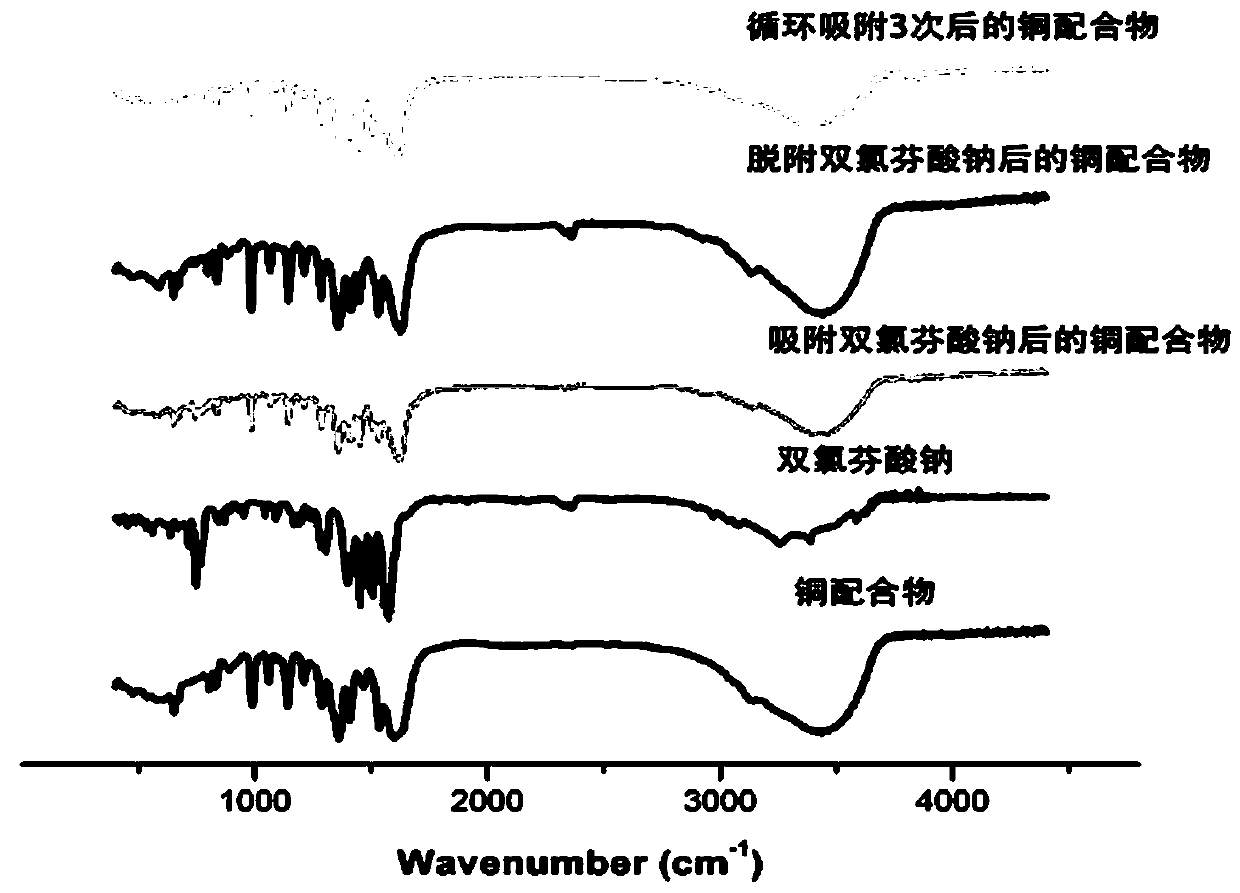

A technology of copper complexes and drugs, which is applied in the field of preparation of copper complexes, can solve the problems of slow degradation process of biological and photodegradation methods, secondary pollution, low adsorption rate of activated carbon, etc., and achieve good recycling ability and good structural stability , The effect of the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of copper complex, comprising the following steps:

[0034] 1) Mix 0.6g of copper chloride dihydrate and 0.2g of 1,4-bis(triazol-1-yl)terephthalic acid, add to 67mL N,N-dimethylformamide and stir well to obtain mixed solution A ; Then add 2.85mL nitric acid and stir for 8min to obtain mixed solution B;

[0035] 2) Take 4 mL of the mixed solution B obtained in step 1) and dispense it into a 15 mL vial, and place the vial at a temperature of 110°C for 14 hours to obtain crystal C;

[0036] 3) Wash the crystal C obtained from step 2) three times with ethanol, then soak the cleaned crystal C in methanol for 2 days, and replace the methanol every 24 hours during this period, and then place the crystal C in dichloromethane Soak for 1 day, and finally place the soaked crystal C in an oven at a temperature of 90° C. to dry for 12 hours to obtain a copper complex.

Embodiment 2

[0038] A preparation method of copper complex, comprising the following steps:

[0039] 1) Mix 1g of copper chloride dihydrate and 0.2g of 1,4-bis(triazol-1-yl)terephthalic acid, then add to 114mL N,N-dimethylformamide and stir well to obtain mixed solution A; Then add 3.85mL nitric acid and stir for 3min to obtain mixed solution B;

[0040] 2) Take 4 mL of the mixed solution B obtained in step 1) and dispense it into a 15 mL vial, and place the vial at a temperature of 130°C for 10 h to obtain crystal C;

[0041] 3) Wash the crystal C obtained from step 2) three times with ethanol, then soak the cleaned crystal C in methanol for 2 days, and replace the methanol every 24 hours during this period, and then place the crystal C in dichloromethane Soak for 1 day, and finally place the soaked crystal C in an oven at a temperature of 110° C. to dry for 8 hours to obtain a copper complex.

Embodiment 3

[0043] A preparation method of copper complex, comprising the following steps:

[0044] 1) Mix 0.7g of copper chloride dihydrate and 0.2g of 1,4-bis(triazol-1-yl)terephthalic acid, then add it into 80mL N,N-dimethylformamide and stir well to obtain a mixed solution A ; Then add 3mL nitric acid and stir for 5min to obtain mixed solution B;

[0045] 2) Take 4 mL of the mixed solution B obtained in step 1) and put it into a 15 mL vial, and place the vial at a temperature of 120°C for 12 hours to obtain crystal C;

[0046]3) Wash the crystal C obtained from step 2) three times with ethanol, then soak the cleaned crystal C in methanol for 2 days, and replace the methanol every 24 hours during this period, and then place the crystal C in dichloromethane Soak for 1 day, and finally place the soaked crystal C in an oven at a temperature of 100° C. to dry for 10 hours to obtain a copper complex.

[0047] In conclusion, the preparation method of copper metal organic framework compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com