Niobium and lead codoped palladium-loaded titanium dioxide/barium titanate nano heterojunction photocatalyst preparation method

A technology of titanium dioxide and photocatalyst, which is applied in the field of lead co-doping, can solve the problems of environmental pollution of waste acid and waste liquid, and achieve the effect of realizing reuse, realizing environmental protection and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

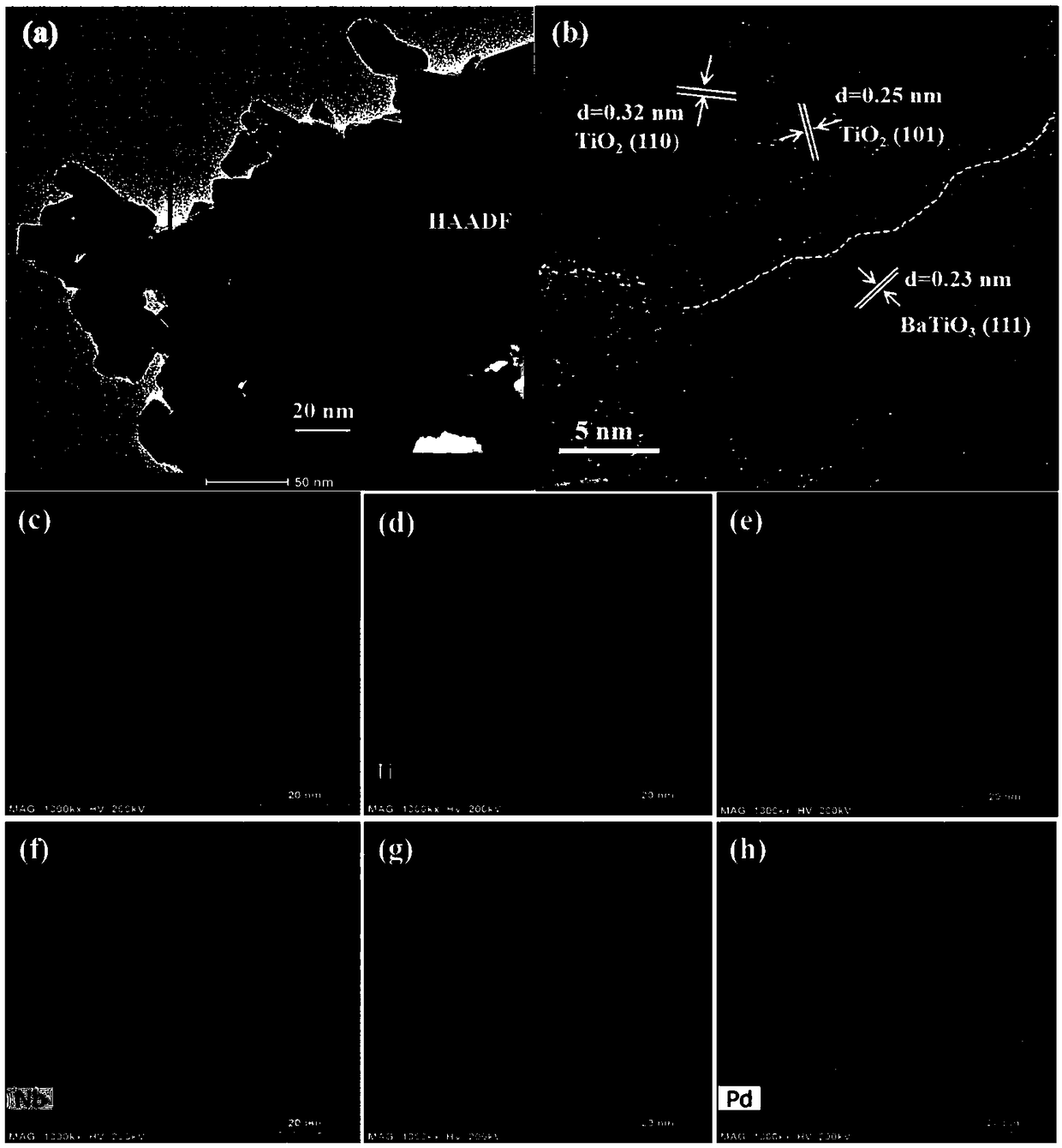

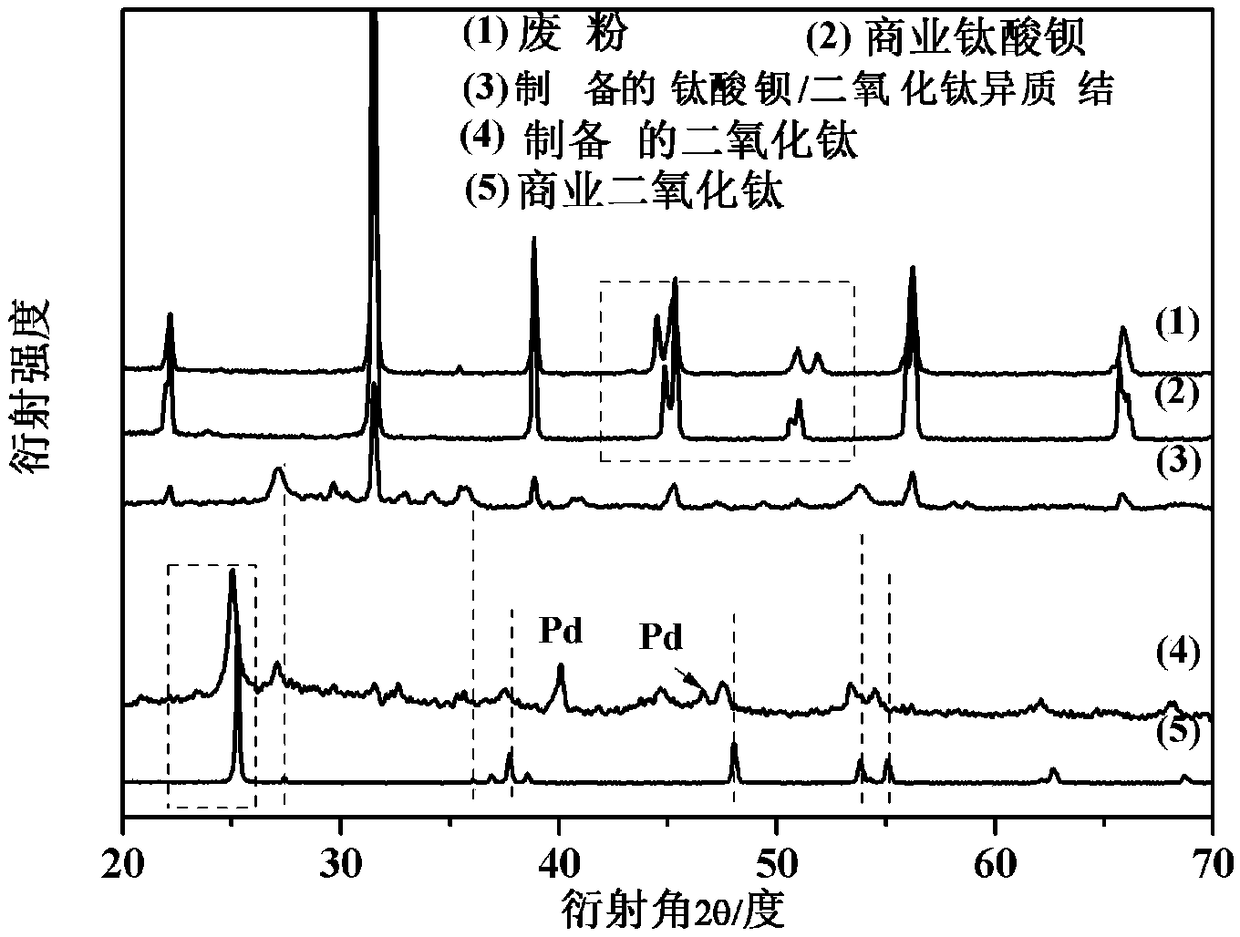

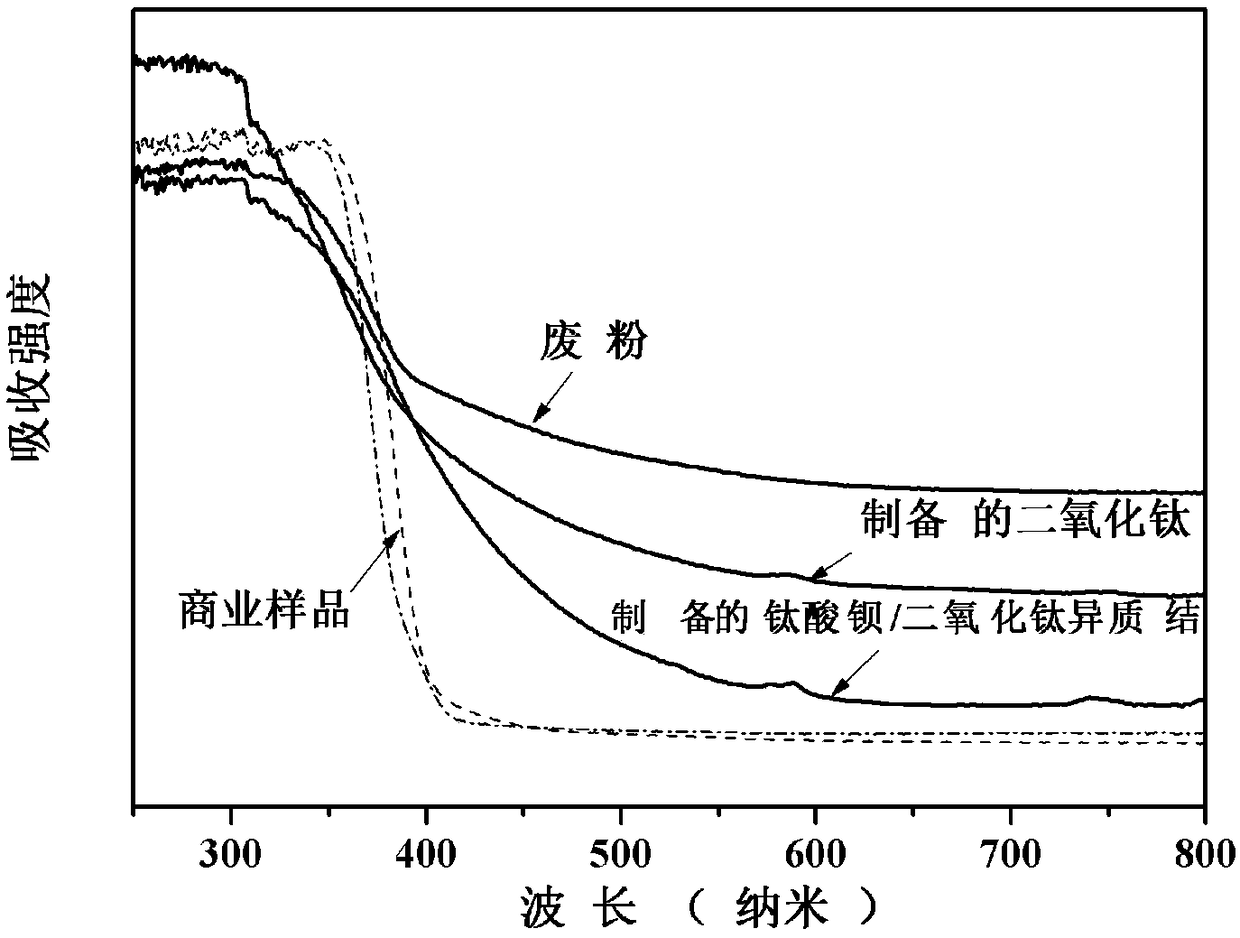

[0024] The method for in-situ preparation of niobium-lead co-doped and palladium-loaded titanium dioxide / barium titanate nano-heterojunction photocatalyst by using waste multilayer ceramic capacitors according to the present invention comprises the following steps:

[0025] 1. Mechanical ball milling and screening of waste multilayer ceramic capacitors, the average particle size of the material is ~0.075mm, and then magnetic separation to separate nickel and iron;

[0026] 2. Evenly mix the powder after magnetic separation with sodium chloride at a mass ratio of 1:1, and then carry out chlorination treatment. The oxygen flow rate was controlled to 50ml / min, the reaction temperature was 400°C, and the reaction time was 4h.

[0027] 3. Filter the residue after the chlorination reaction through deionized water and sodium thiosulfate to separate barium chloride and silver chloride;

[0028] 4. Dry the filtered residue at 120° C. to obtain a niobium-lead co-doped titanium dioxide / ...

Embodiment 2

[0030] The method for in-situ preparation of niobium-lead co-doped and palladium-loaded titanium dioxide / barium titanate nano-heterojunction photocatalysts described in the application of the present invention comprises the following steps:

[0031] 1. Mechanical ball milling and screening of waste multilayer ceramic capacitors, the average particle size of the material is ~0.075mm, and then magnetic separation to separate nickel and iron;

[0032] 2. Evenly mix the powder after magnetic separation with ammonium chloride at a mass ratio of 1:2, and then carry out chlorination treatment. The oxygen flow rate is controlled to 80ml / min, the reaction temperature is 500°C, and the reaction time is 2h.

[0033] 3. Filter the residue after the chlorination reaction through deionized water and sodium thiosulfate to separate barium chloride and silver chloride;

[0034] 4. Dry the filtered residue at 120° C. to obtain a niobium-lead co-doped titanium dioxide / barium titanate nano-heter...

Embodiment 3

[0036] The method for in-situ preparation of niobium-lead co-doped and palladium-loaded titanium dioxide / barium titanate nano-heterojunction photocatalysts described in the application of the present invention comprises the following steps:

[0037] 1. Mechanical ball milling and screening of waste multilayer ceramic capacitors, the average particle size of the material is ~0.075mm, and then magnetic separation to separate nickel and iron;

[0038] 2. Evenly mix the powder after magnetic separation with ferrous chloride at a mass ratio of 1:3, and then carry out chlorination treatment. The oxygen flow rate is controlled to 100ml / min, the reaction temperature is 600°C, and the reaction time is 0.5h.

[0039] 3. Filter the residue after the chlorination reaction through deionized water and sodium thiosulfate to separate barium chloride and silver chloride;

[0040] 4. Dry the filtered residue at 120° C. to obtain a niobium-lead co-doped titania catalyst with a particle size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com