Steel slag micro-powder selecting system utilizing waste heat flue gas of steel plant

A technology for iron and steel slag and iron and steel plants, applied in the field of iron and steel slag micropowder separation systems, can solve the problems of direct waste heat discharge, insufficient utilization, poor stability, etc., to reduce fuel costs, avoid heat loss, and fast heating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

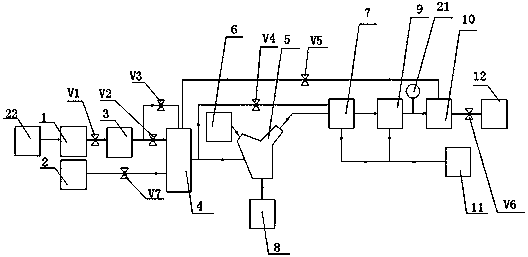

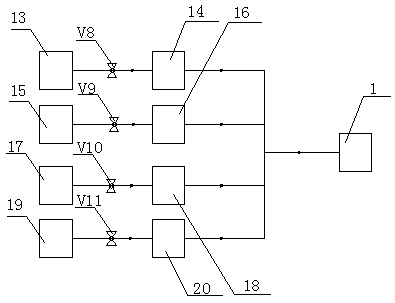

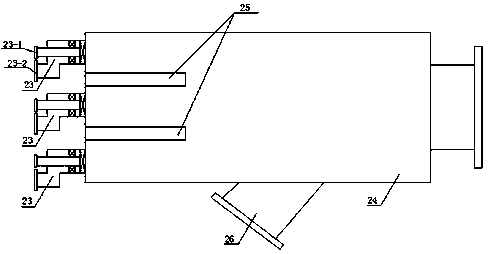

[0021] Such as figure 1 As shown, a steel slag fine-powder separation system utilizing the waste heat flue gas of a steel plant includes a waste heat flue gas source 22 of the steel plant, a waste heat flue mechanism 1 for gathering waste heat flue gas from multiple places in the steel plant, and a waste heat flue gas Booster mechanism 3, gas source 2, post-combustion hot blast stove 4, static powder separator 5, feeding mechanism 6, coarse material storage mechanism 8, cyclone 7, dust removal mechanism, fine material storage mechanism 11 and exhaust mechanism 12 ;

[0022] The dust removal mechanism includes a bag filter 9 and a dust removal fan 10, the gas outlet of the bag filter 9 is connected to the gas inlet of the dust removal fan 10, and the bag filter 9 and the dust removal fan 10 form a two-stage dust removal mechanism to further reduce particulate matter in the exhaust gas , to prevent particulate matter from polluting the environment.

[0023] The waste heat flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com