Steel acid pickling wastewater treatment system

A technology for pickling wastewater and steel products, which is applied in metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve problems such as soil pollution, poor acid resistance, and insufficient efficiency, and achieve economical production efficiency. Reduced flushing frequency and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

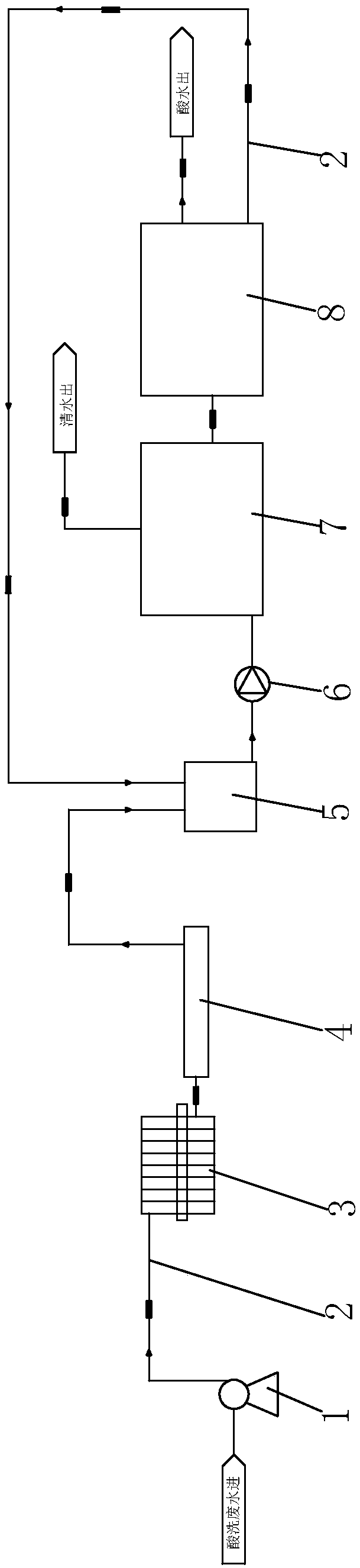

[0015] See figure 1 , the steel pickling wastewater treatment system of the present embodiment mainly consists of a raw water pump 1, an infusion pipeline 2, a filter press 3, a cross-flow organic tubular ultrafiltration membrane device 4, a mixed liquid container 5, a booster pump 6, a reverse osmosis The membrane device 7 and the nanofiltration membrane device 8 are composed.

[0016] Raw water pump 1, filter press 3, cross-flow organic tubular ultrafiltration membrane device 4 and booster pump 6 all have a liquid inlet and a liquid outlet; the mixed liquid container 5 is provided with a first liquid inlet and a second liquid inlet and liquid outlet; the reverse osmosis membrane device 7 has a liquid inlet, a clear water outlet and a concentrated water outlet; the nanofiltration membrane device 8 has a liquid inlet, a reclaimed water outlet and an acid water outlet.

[0017] The liquid inlet of the filter press 3 is connected to the liquid outlet of the raw water pump 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com