Sludge anaerobic treatment method and system

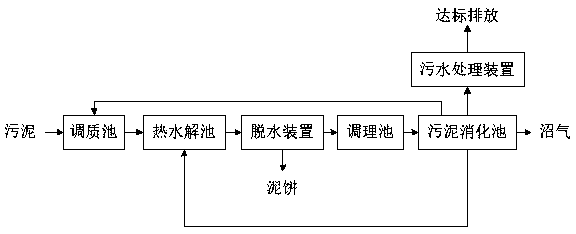

An anaerobic treatment, sludge technology, applied in the direction of biological sludge treatment, dehydration/drying/thickened sludge treatment, pyrolysis treatment of sludge, etc., can solve the problem of low organic matter content of effluent sludge and water content of effluent sludge Low yield, high organic matter content and other problems, to achieve the effect of increasing the total biogas production, good dehydration, and low organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A certain municipal sludge has an organic matter content of 42%, adjust its water content to 90%, and heat-treated the sludge after thermal hydrolysis. The organic matter content of the sludge after thermal hydrolysis is 29%, and the sludge after thermal hydrolysis The sludge is dehydrated, and the released aqueous solution enters the sludge digester for anaerobic digestion, and the dehydrated sludge forms a mud cake for export; anaerobic digestion produces biogas, and the gas production is 41.26Nml / g, and the biogas residue and the organic matter of the biogas residue are discharged The content is 59%. After the biogas residue is dehydrated, part of the water enters the conditioning tank to adjust the moisture content of the sludge, and part of the water enters the sewage treatment device. The degraded sludge undergoes thermal hydrolysis reaction together.

Embodiment 2

[0029] A certain municipal sludge has an organic matter content of 27%, adjust its moisture content to 93%, and heat-hydrolyze the sludge after conditioning. The organic matter content of the sludge after thermal hydrolysis is 15%, and the sludge after thermal hydrolysis The sludge is dehydrated, and the released aqueous solution enters the sludge digester for anaerobic digestion, and the dehydrated sludge forms a mud cake for export; anaerobic digestion produces biogas, and the gas production is 31.71Nml / g, and the biogas residue is discharged, and the organic matter content of the biogas residue is After the biogas residue is dehydrated, part of the water enters the conditioning tank to adjust the moisture content of the sludge, part of the water enters the sewage treatment plant, and is discharged up to the standard after treatment. The dehydrated biogas residue enters the thermal hydrolysis tank for conditioning and conditioning The final sludge is subjected to thermal hydr...

Embodiment 3

[0031] A certain municipal sludge, its organic matter content is 55%, adjust its water content to 92%, the sludge after conditioning is subjected to thermal hydrolysis, the organic matter content of the sludge after thermal hydrolysis is 33%, and the sludge after thermal hydrolysis The sludge is dehydrated, and the released aqueous solution enters the sludge digester for anaerobic digestion, and the dehydrated sludge forms a mud cake for export; anaerobic digestion produces biogas, the gas production is 52.18Nml / g, and the biogas residue is discharged, and the organic matter content of the biogas residue is After the biogas residue is dehydrated, part of the water enters the conditioning tank to adjust the moisture content of the sludge, part of the water enters the sewage treatment plant, and is discharged up to the standard after treatment. The dehydrated biogas residue enters the thermal hydrolysis tank for conditioning and tempering The final sludge is subjected to thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com