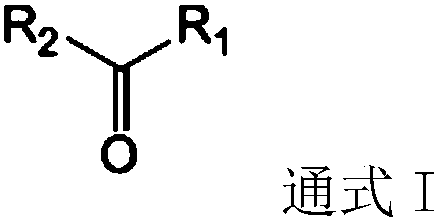

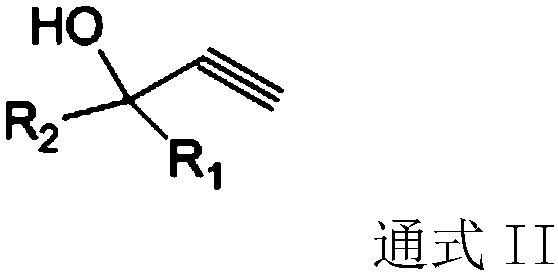

Method for efficiently preparing alkynol

An alkynol, high-efficiency technology, applied in the field of chemical intermediates and chemical preparation, can solve problems such as low conversion rate, and achieve the effects of high conversion rate, good product purity, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

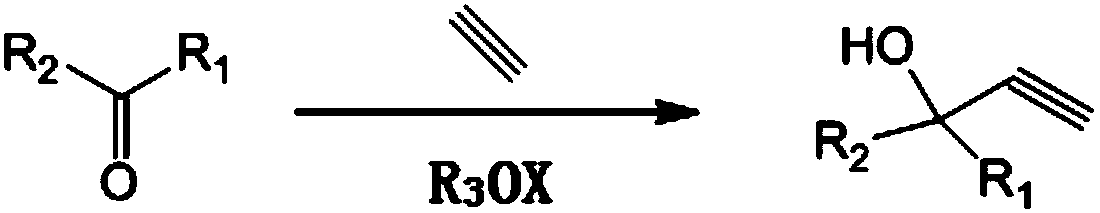

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, preparation methyl butynyl alcohol

[0037] In a 10L three-necked flask, 6L of anhydrous methanol was added, protected by nitrogen, and 550g of sodium metal (small pieces) was slowly added under ice-water cooling. After the sodium metal is completely dissolved, add 1.5 L of acetone, stir evenly, and cool to below 0°C. Slowly feed acetylene, and control the flow of acetylene so that the reaction temperature is preferably at 0-5°C. When the reaction is no longer exothermic, it is the end of the reaction. Then feed a small amount of acetylene, and react for 0.5 hours under airtight micro-positive pressure (the nitrogen balloon does not become larger).

[0038] In another 20L three-necked flask, add 2.5 kg of ammonium chloride and 3L of methanol. Under ice water cooling, the reaction solution was poured into the ammonium chloride system for neutralization reaction. Control the neutralization reaction temperature to less than 20°C. After neutralization, fi...

Embodiment 2

[0039] Embodiment 2, preparation methyl butynol

[0040] In a 500L stainless steel reaction kettle, 300L of anhydrous methanol was added under nitrogen protection. Under jacket frozen brine cooling, slowly add metal sodium block 20kg. After the metallic sodium is completely dissolved, add 55 L of acetone, stir evenly, and cool to below 0°C. Slowly feed acetylene, and control the flow of acetylene so that the reaction temperature is preferably at 0-5°C. When the reaction is no longer exothermic, it is the end of the reaction. Then a small amount of acetylene was passed through, and the airtight micro positive pressure was reacted for 1 hour. In another 1000L glass-lined reactor, add 150 kg of ammonium chloride and 300L of methanol. Under the cooling of frozen brine, the reaction liquid is pumped into the ammonium chloride system for neutralization reaction. Control the neutralization reaction temperature to less than 20°C. After neutralization, filter. The filtrate was f...

Embodiment 3

[0041] Embodiment 3, preparation methyl butynol

[0042] In a 500L stainless steel reaction kettle, 300L of anhydrous tert-butanol was added under nitrogen protection. Under jacket frozen brine cooling, slowly add metal potassium block 20kg. After the potassium metal is completely dissolved, add 33 L of acetone, stir evenly, and cool to below 0°C. Slowly feed acetylene, and control the flow of acetylene so that the reaction temperature is preferably at 0-5°C. When the reaction is no longer exothermic, it is the end of the reaction. Then a small amount of acetylene was passed through, and the airtight micro positive pressure was reacted for 1 hour. In another 1000L glass-lined reactor, add 100 kg of ammonium chloride and 200L of methanol. Under the cooling of frozen brine, the reaction liquid is pumped into the ammonium chloride system for neutralization reaction. Control the neutralization reaction temperature to less than 20°C. After neutralization, filter. The filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com