Method for preparing cyclopentanone

A technology of cyclopentanone and furfural, applied in the field of preparing bio-based cyclopentanone, can solve the problems of low separation yield, high catalyst cost, unreachable cyclopentanone yield and the like, and achieves high yield, long life, The effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

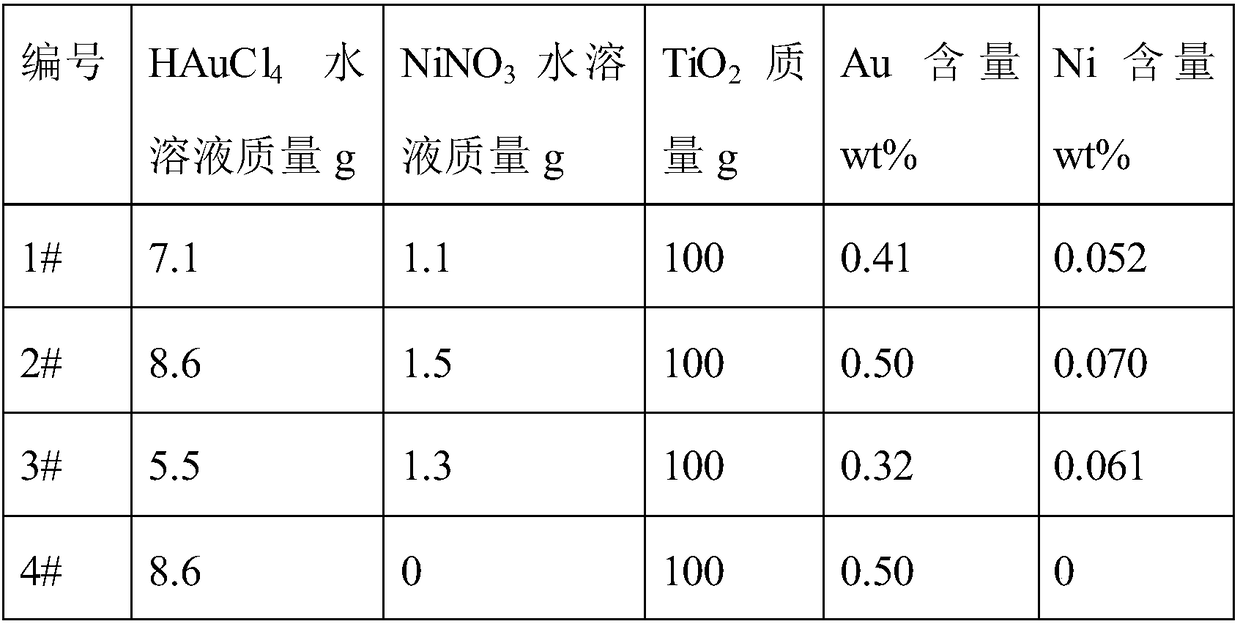

Embodiment 1

[0061] Add 2kg of solvent (water: tetrahydrofuran = 2:1, mass ratio) into a 10L stirred 316L stainless steel high-pressure hydrogenation kettle, and add about 50g of 1#Au-Ni / TiO 2 catalyst. The reactor was sealed and replaced three times with 1Mpa nitrogen, and then three times with 1Mpa hydrogen containing 50ppm carbon dioxide. Then open the reactor and stir to 600 rpm, and increase the temperature in the reactor to 130°C, and use the aforementioned hydrogen containing 50ppm carbon dioxide to increase the pressure in the reactor to 3MPa, then change the hydrogen source from the aforementioned hydrogen containing 50ppm carbon dioxide The hydrogen switch is 99.999% pure and CO free 2 of hydrogen. Then, furfural was added to the reactor at a rate of 200 g / h by a high-pressure advection pump, and the temperature of the reactor was kept at 130° C. and the pressure at 3 Mpa (G) during the process. The reaction was continued for 10 hours and stopped. Sampling analysis showed tha...

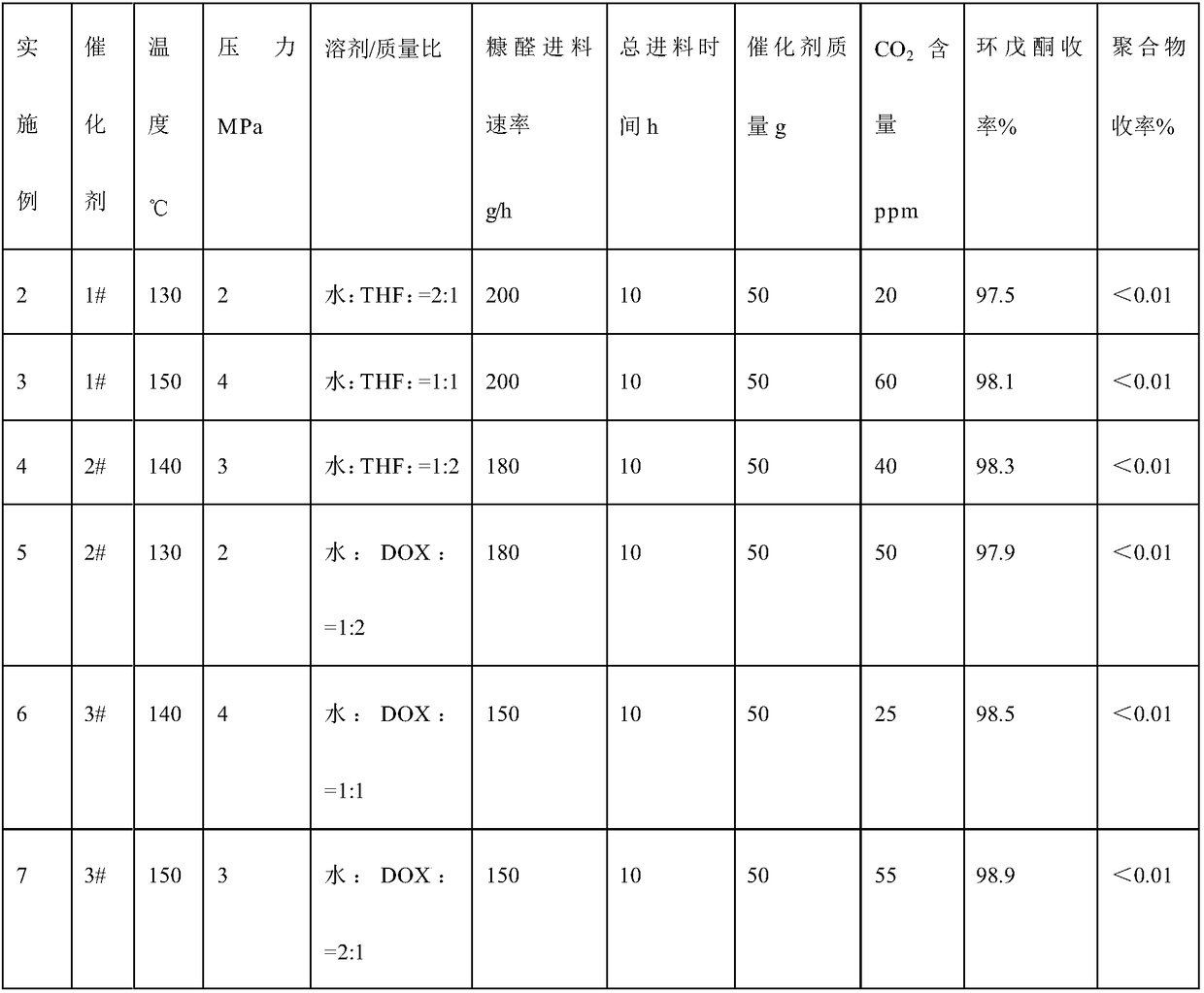

Embodiment 2-6

[0063] Other conditions were consistent with Example 1, and the other conditions were changed to the parameters shown in the following table, the reaction product was sampled and analyzed and the product was separated by rectification to obtain the cyclopentanone product. The experimental conditions and analysis results are shown in Table 2 below.

[0064] Table 2 embodiment 2-6 reaction condition and result

[0065]

[0066] Note: THF: Tetrahydrofuran DOX: Dioxane

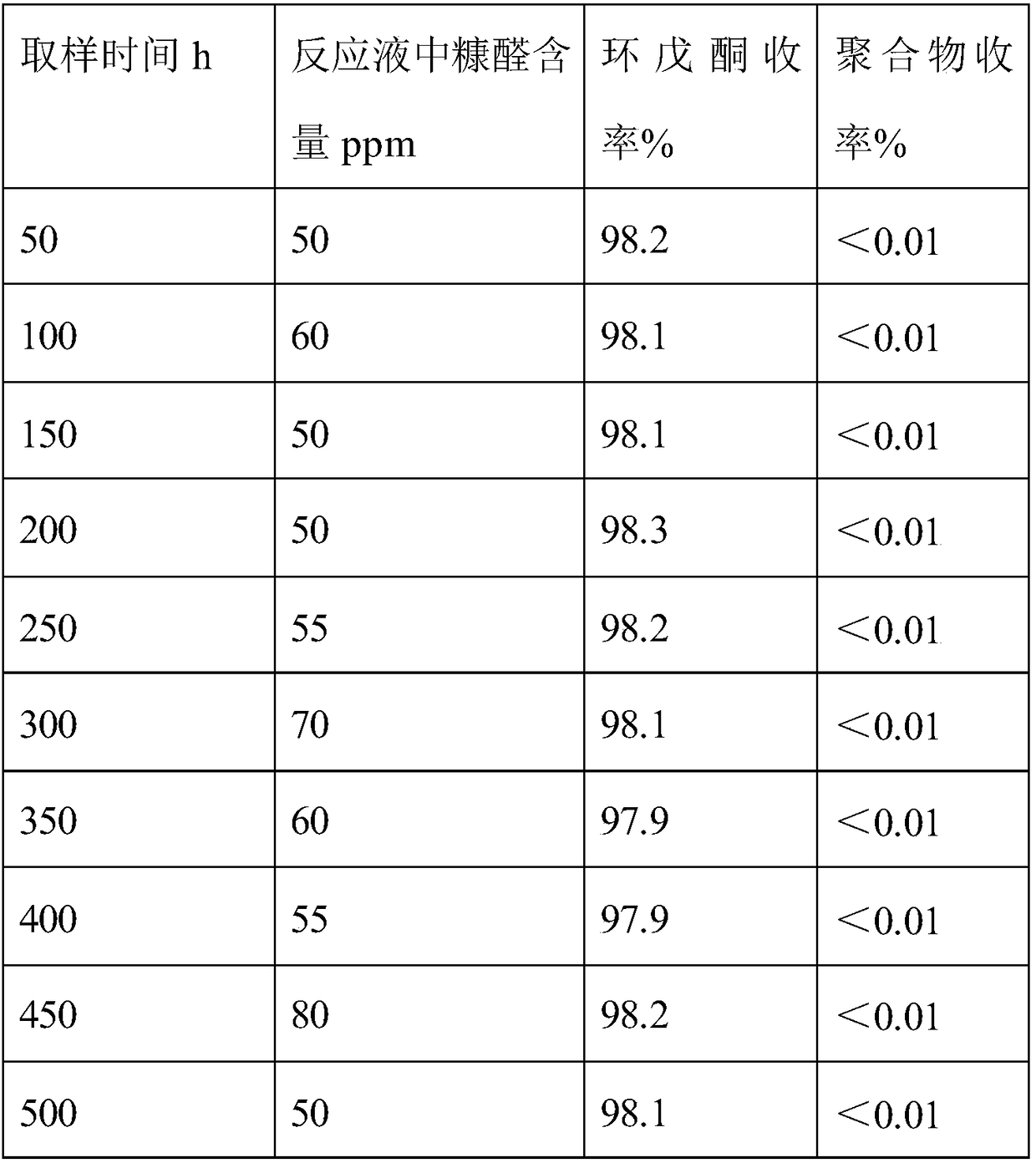

Embodiment 8

[0068] Add 2kg of solvent (the solvent is a THF to water solution with a mass ratio of 1:1) into a 10L stirred 316L stainless steel high-pressure hydrogenation kettle, and add about 50g of 1#Au-Ni / TiO 2 catalyst. The reactor was sealed and replaced three times with 1Mpa nitrogen, and then three times with 1Mpa hydrogen containing 50ppm carbon dioxide. Then the reactor was turned on and stirred to 600 rpm, and the temperature inside the reactor was increased to 130° C., and the pressure was increased to 3 MPa. Add furfural solution at a rate of 200g / h (the furfural / solvent mass ratio is 1:1, and the solvent is a mixture of THF and water with a mass ratio of 1:1). Go out cyclopentanone reaction mother liquor. Through the online gas detection device on the reactor, detect the content of carbon dioxide in the gas phase of the reactor, and through the switch of the carbon dioxide flow control valve, keep the content of carbon dioxide in the gas phase of the reactor at 50ppm. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com