High-voltage insulated bus and coating technology

A high-voltage insulation and busbar technology, which is applied in the field of busbar manufacturing, can solve problems such as increased maintenance, inspection difficulty, unsuitable for large-scale promotion, and lack of installation conditions, etc., to achieve good moisture-proof and hydrophobic performance, excellent electrical insulation, and improve insulation safety The effect of sex and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

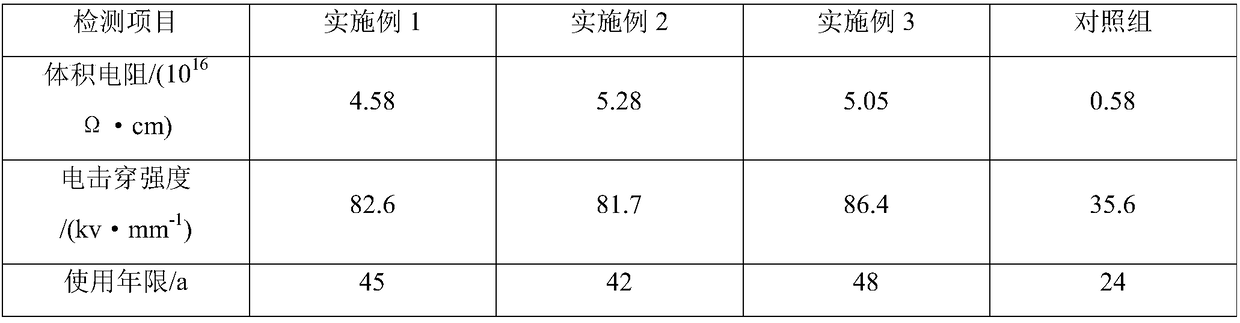

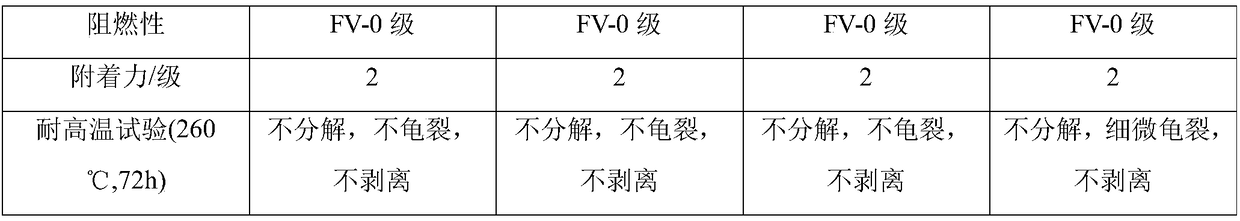

Embodiment 1

[0022] A high-voltage insulated busbar provided by the present invention includes a body, which is coated with a primer layer and a topcoat layer, and the primer layer is coated with any one of epoxy paint, acrylic paint or silicone paint, and the thickness is 15 μm; the topcoat layer is coated with silicone paint with a thickness of 10 μm.

[0023] The topcoat layer includes the following components in parts by weight: 75 parts of silicone resin, 35 parts of ethylene glycol ether acetate, 15 parts of aluminum hydroxide, 7 parts of methacryloxytrimethoxysilane coupling agent , 5 parts of silicon dioxide, 3 parts of silicone oil, 9 parts of dibutyltin dilaurate.

[0024] The preparation process of the topcoat layer is as follows:

[0025] Add the silicone resin and ethylene glycol ethyl ether acetate into the reaction kettle and mix evenly, the mixing time is 90min, the mixing temperature is 55°C, and the mixing speed is 220r / min; add methacryloxytrimethoxysilane coupling agen...

Embodiment 2

[0033] A high-voltage insulated busbar provided by the present invention includes a body, which is coated with a primer layer and a topcoat layer, and the primer layer is coated with any one of epoxy paint, acrylic paint or silicone paint, and the thickness The thickness is 21 μm; the topcoat layer is coated with silicone paint, and the thickness is 13 μm.

[0034] The topcoat layer includes the following components in parts by weight: 85 parts of silicone resin, 37 parts of ethylene glycol ether acetate, 18 parts of aluminum hydroxide, 8 parts of methacryloxytrimethoxysilane coupling agent , 6 parts of silicon dioxide, 4 parts of silicone oil, 11 parts of dibutyltin dilaurate.

[0035] The preparation process of the topcoat layer is as follows:

[0036] Add the silicone resin and ethylene glycol ethyl ether acetate into the reaction kettle and mix evenly, the mixing time is 100min, the mixing temperature is 58°C, and the mixing speed is 230r / min; add methacryloxytrimethoxysi...

Embodiment 3

[0044] A high-voltage insulated busbar provided by the present invention includes a body, which is coated with a primer layer and a topcoat layer, and the primer layer is coated with any one of epoxy paint, acrylic paint or silicone paint, and the thickness is 25 μm; the topcoat layer is coated with silicone paint with a thickness of 15 μm.

[0045] The topcoat layer comprises the following components in parts by weight: 95 parts of silicone resin, 40 parts of ethylene glycol ethyl ether acetate, 20 parts of aluminum hydroxide, 9 parts of methacryloxytrimethoxysilane coupling agent , 7 parts of silicon dioxide, 4 parts of silicone oil, 12 parts of dibutyltin dilaurate.

[0046] The preparation process of the topcoat layer is as follows:

[0047] Add the silicone resin and ethylene glycol ethyl ether acetate into the reaction kettle and mix evenly, the mixing time is 110min, the mixing temperature is 60°C, and the mixing speed is 240r / min; add methacryloxytrimethoxysilane coup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com