Anti-radiation damage metal nanocrystalline/carbon nano tube composite material and preparation method thereof

A metal nanocrystal and carbon nanotube technology, applied in metal material coating process, nanotechnology, nanotechnology and other directions, to achieve the effects of good thermal conductivity and electrical conductivity, good thermal stability, high thermal stability and radiation damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The invention uses the metal nickel (Ni) / CNT composite material to illustrate the implementation of the radiation damage resistant metal nanocrystal / carbon nanotube composite material and the preparation method thereof.

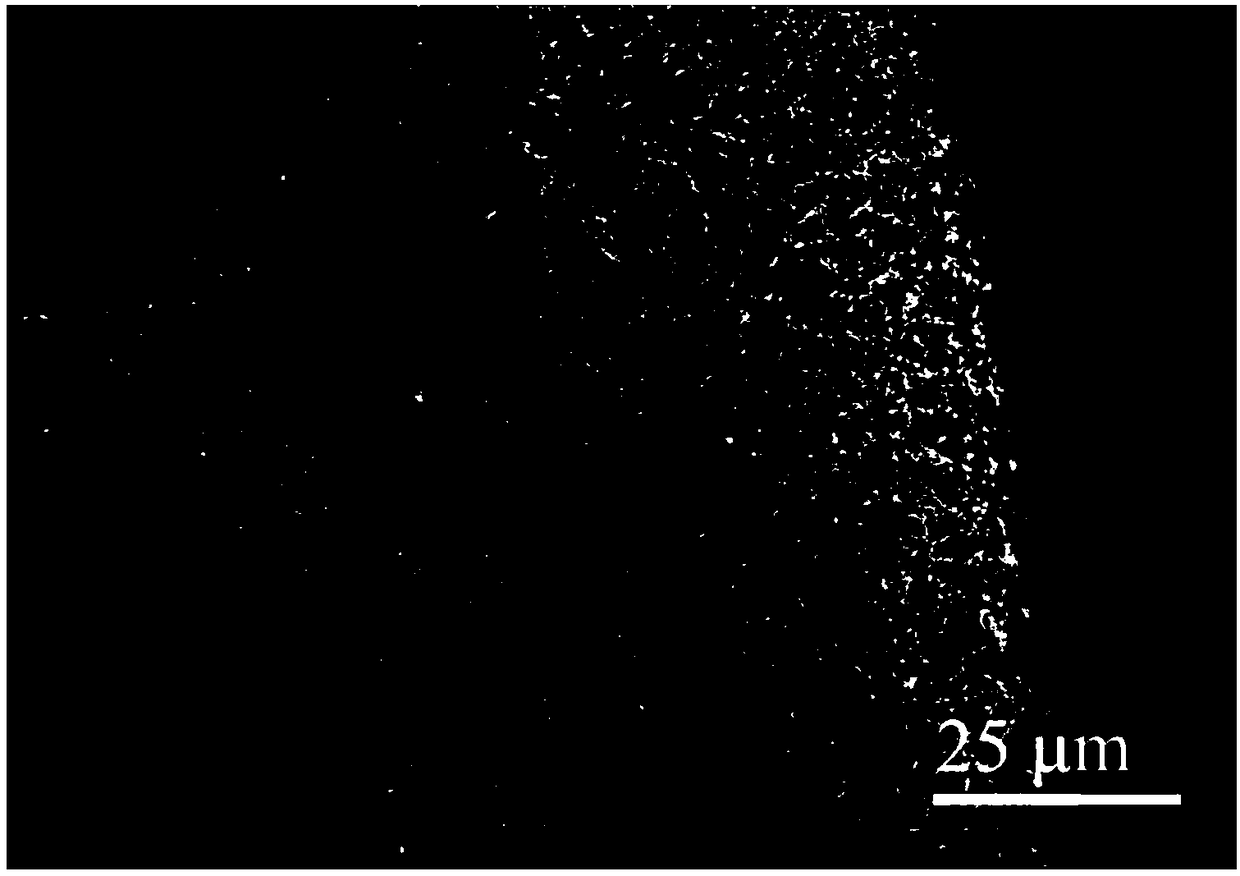

[0043] In this embodiment, the high-performance radiation-resistant Ni nanocrystal / CNT composite material mainly includes: a high-quality self-supporting carbon nanotube matrix with a tube bundle structure and Ni nanocrystals uniformly deposited on the surface of the CNT, and the volume fraction of the CNT matrix is less than 10 %, with a high-density nanoscale porous structure, such as figure 1 shown.

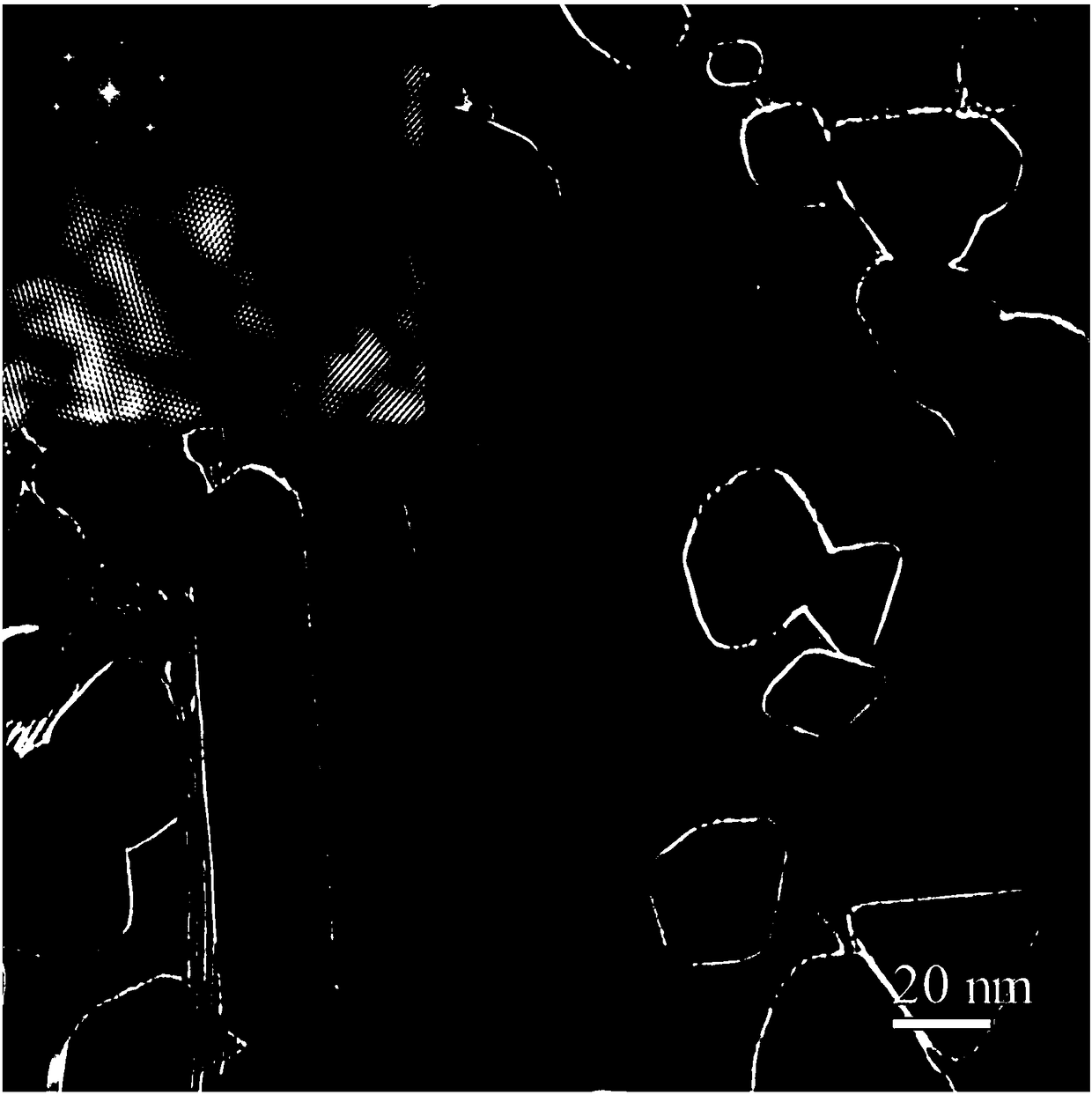

[0044] Ni nanocrystals uniformly deposited on the surface of CNT, the grain size perpendicular to the axis of the carbon tube is ≤250nm, the porosity is ≥50%, and it can be continuously adjusted, such as figure 2 shown. Ni nanocrystals have good bonding force with CNT matrix, and there is no peeling phenomenon between metal nanocrystals and CNT m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com