Functional separator for improving performance of lithium-sulfur battery and lithium-sulfur battery employing functional separator

A lithium-sulfur battery and separator technology, applied in the field of electrochemistry, can solve problems such as reducing the operability of practical applications, reducing battery power density, and hindering positive ion transmission, and achieving good application prospects, fast migration rate, and improved cycle and rate. Poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

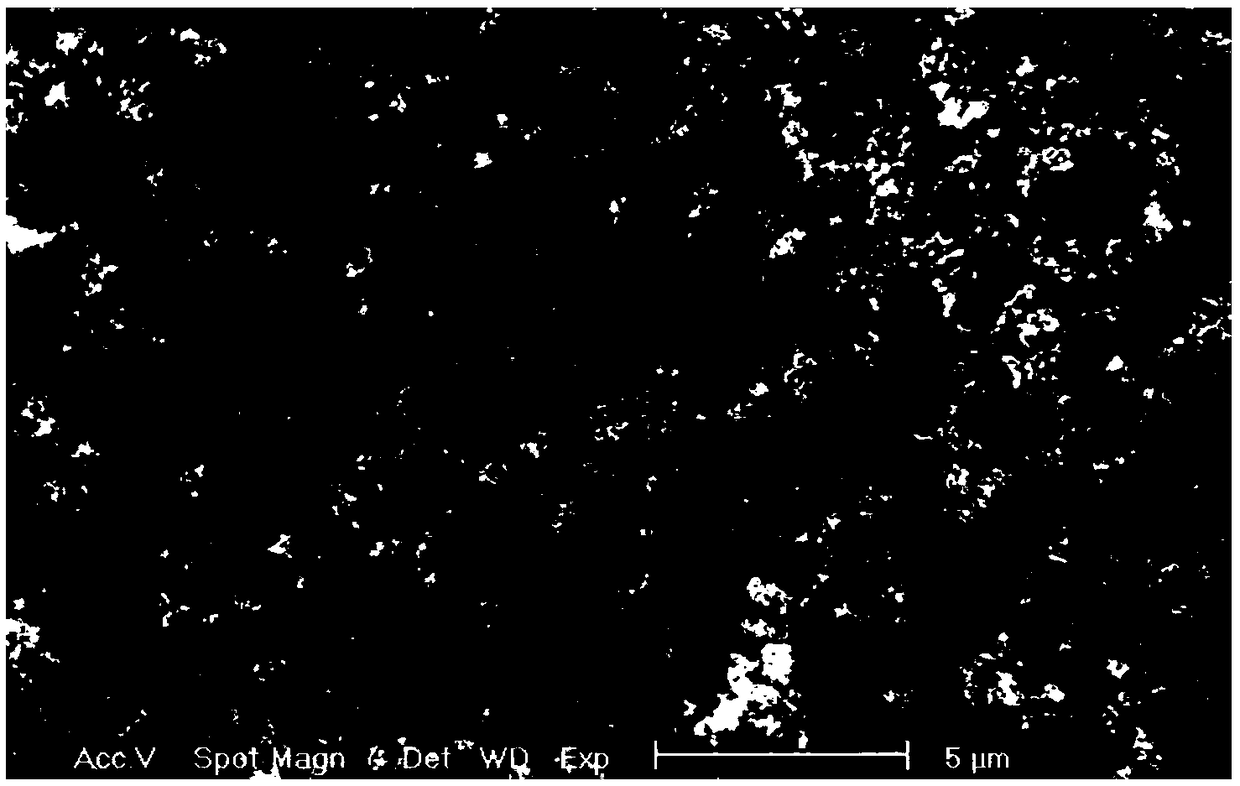

[0026] Disperse metal copper powder and carbon black with a particle size of 50 nanometers in a solution with a volume ratio of 3:1 between deionized water and acetone according to the mass ratio of 90:10, and add 6% of the total mass of the metal copper powder and carbon black. After the vinyl alcohol was mechanically stirred for 5 hours, a coating slurry was formed, and the obtained slurry was coated on one side surface of the polyethylene diaphragm on a coating machine, and the functional diaphragm was obtained after drying. The surface morphology of the functional membrane is as follows figure 1 shown.

Embodiment 2

[0028] Disperse metal copper powder and carbon nanotubes with a particle size of 1 micron in N, N dimethylformamide at a mass ratio of 95:5, and add polymethacrylic acid with a total mass of 10% of the metal copper powder and carbon nanotubes Ultrasonic dispersion after methyl ester for 2 hours to form a coating slurry, and the resulting slurry was carried out on one side surface of a polyvinylidene fluoride-hexafluoropropylene copolymer microporous polymer membrane prepared by a phase inversion method on a coating machine After coating and drying, a functional separator can be obtained.

Embodiment 3

[0030] Disperse metal copper powder, graphene, and acetylene black with a particle size of 5 microns in deionized water according to a mass ratio of 85:10:5, and add metal copper powder, graphene, and carboxymethyl fiber with 15% of the total mass of acetylene black Sodium sodium (CMC) and styrene-butadiene rubber (SBR) (the mass ratio of the two is 5:5) was dispersed by ball milling for 10 hours to form a coating slurry, which was coated on polypropylene-polyethylene- On the surface of one side of the polypropylene three-layer composite membrane, the functional membrane can be obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com