Short pore passage mesoporous cathode material for lithium ion battery and preparation method

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of nano-material preparation process and high production cost, and alleviate the problems of poor low-temperature discharge performance, electrical conductivity and lithium ion diffusion rate The effect of increasing and increasing the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

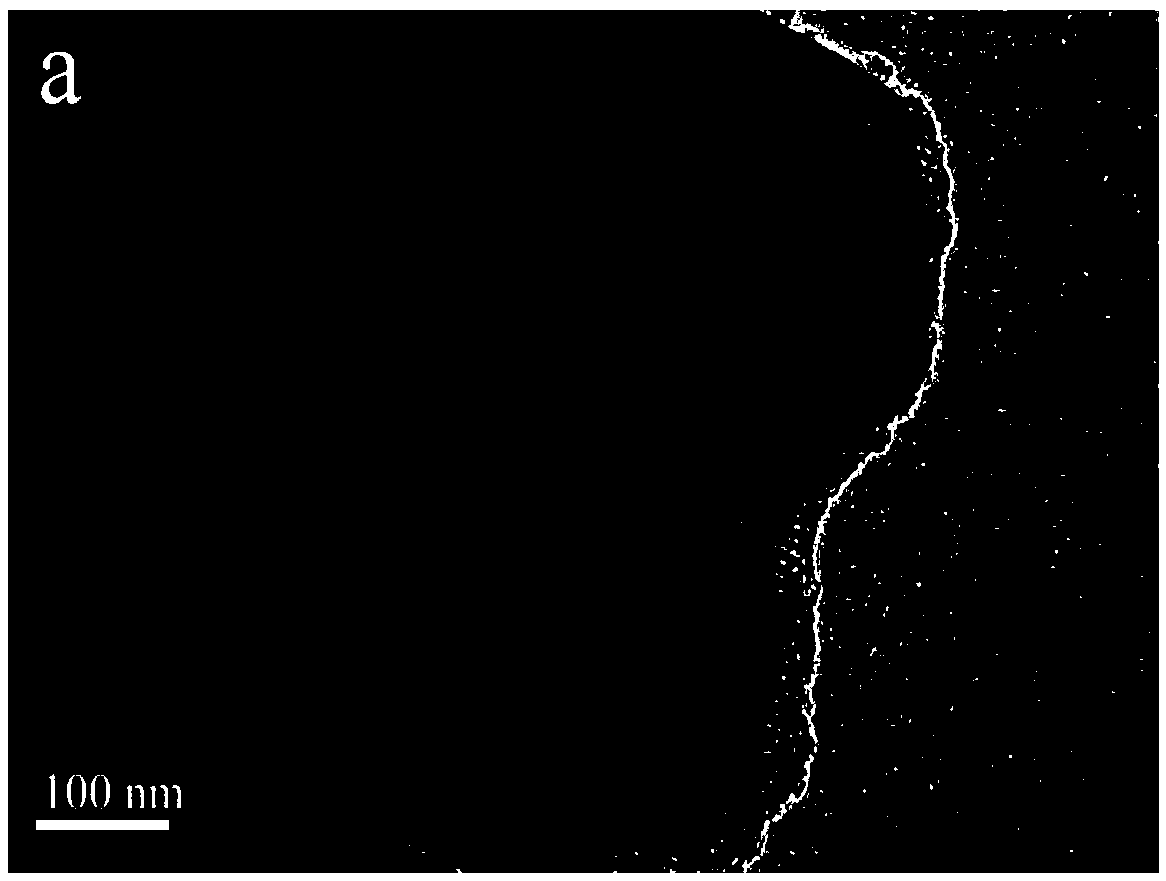

[0038]Add 4.4g of cetyltrimethylammonium bromide (CTAB), 147g of deionized water, and 10.3g of phosphoric acid into the reaction kettle, stir for 4 hours at 45°C, and then slowly add 2.14g of Zirconium oxychloride, 14.3g ferric chloride and 6.5g lithium acetate, after continuing to stir for 24h, transfer the reaction mixture into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, crystallize at 100°C for 24h, use Filter and wash with ionic water to obtain a precipitate, dry the precipitate, then raise the temperature to 600°C at a rate of 4°C / min under the protection of Ar atmosphere, and continue to bake for 6h to obtain the short-channel mesoporous positive electrode Material; the pore length of the short-channel mesoporous cathode material detected by scanning electron microscopy is 300nm, the thickness of the carbon coating is 3nm, and the conductivity measured by the probe method is 1.10×10 -2 S / cm.

[0039] The method of making the experimental battery...

Embodiment 2

[0042] Add 4.4g of cetyltrimethylammonium bromide (CTAB), 147g of deionized water, and 10.3g of phosphoric acid into the reaction kettle, stir for 4 hours at 45°C, and then slowly add 1.78g of Zirconium oxychloride, 14.6g ferric chloride and 6.5g lithium acetate, after continuing to stir for 24h, transfer the reaction mixture into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, crystallize at 100°C for 24h, use Filter and wash with ionic water to obtain a precipitate, dry the precipitate, and then raise the temperature to 600°C at a rate of 4°C / min under the protection of Ar atmosphere, and continue to bake for 6h to obtain the short-channel mesoporous positive electrode Material; the pore length of the short-channel mesoporous cathode material detected by scanning electron microscopy is 500nm, the thickness of the carbon coating is 2nm, and the conductivity measured by the probe method is 1.07×10 -3 S / cm.

[0043] An experimental battery was prepared acc...

Embodiment 3

[0046] Add 4.4g of octadecyldimethylbenzyl quaternary ammonium chloride, 147g of deionized water, and 10.3g of phosphoric acid into the reaction kettle, stir at 45°C for 4h, and then slowly add 2.67g of Zirconium oxychloride, 13.8g ferric chloride and 6.5g lithium acetate, after continuing to stir for 24h, transfer the reaction mixture into a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, crystallize at 100°C for 24h, use Filter and wash with ionized water to obtain a precipitate, dry the precipitate, and then raise the temperature to 680°C at a rate of 4°C / min under the protection of an Ar atmosphere, and continue to bake for 6 hours to obtain the short-channel mesoporous cathode Material; the pore length of the short-channel mesoporous cathode material detected by scanning electron microscopy is 580nm, the thickness of the carbon coating is 4nm, and the conductivity measured by the probe method is 6.01×10 -4 S / cm.

[0047] An experimental battery was pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com