a high-protein yogurt

A high-protein, yogurt technology, applied in the direction of milk preservation, milk preparations, milking equipment, etc., can solve the problems of affecting consumer acceptance, increasing the purchase cost of raw and auxiliary materials, and flavor defects of yogurt products, so as to achieve better preservation , equipment cost reduction, and the effect of increasing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

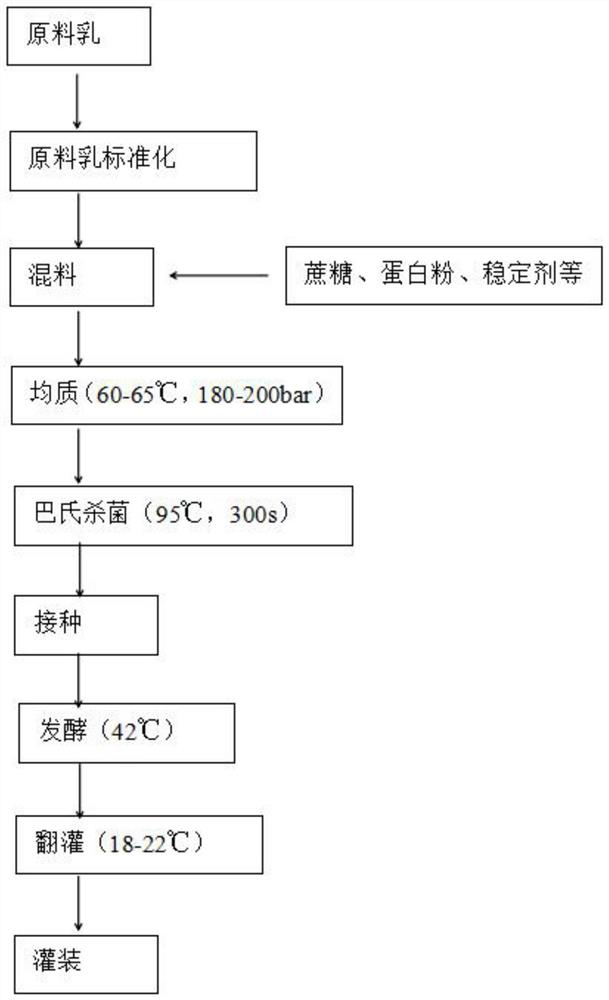

Method used

Image

Examples

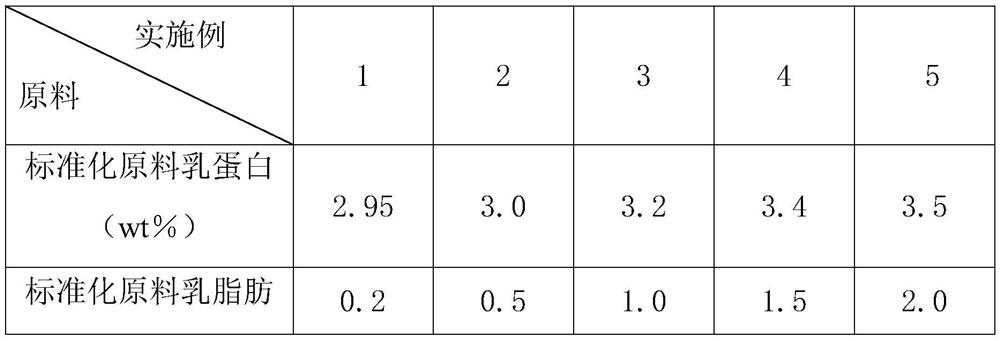

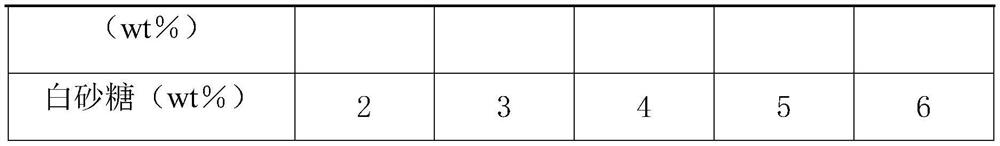

Embodiment 1

[0054] A high-protein yogurt, the yogurt is made of the following raw materials in mass percentage: 2% white granulated sugar; 0.5% Lactobacillus bulgaricus; 0.02% Streptococcus thermophilus, and the balance is milk, which is mixed and fermented and then dewheyed . Its specific preparation method comprises the following steps:

[0055] A standardized pretreatment of milk

[0056] Fresh milk is taken and subjected to standardized pretreatment, specifically including skimming standardization and protein standardization, specifically skimming milk by centrifugal separation technology, and controlling the fat content at 0.2%. Protein standardization Specifically, the milk was standardized to a milk protein content of 2.95% by a single-effect falling film evaporator. Thereby obtaining standardized raw milk with a milk protein content of 2.95% and a milk fat content of 0.2%;

[0057] B ingredients

[0058] Batch the standardized raw milk obtained in step A, add 2% white granulat...

Embodiment 2

[0068] The high-protein yoghurt is prepared from the following raw materials in mass percentage: 3% of white sugar; 0.02% of Lactobacillus bulgaricus; 0.6% of Streptococcus thermophilus, and the balance is milk, which is mixed and fermented and then dewheyed. Its preparation method comprises the following steps:

[0069] A standardized pretreatment of milk

[0070] Take fresh milk and carry out standardized pretreatment of skimming, specifically including standardization of skimming and standardization of protein, specifically skimming milk by centrifugal separation technology, and controlling the fat content at 0.5%. Protein standardization Specifically, the milk was standardized to a milk protein content of 3.0% by a single-effect falling film evaporator. Thereby standardizing the milk into standardized raw milk with a milk protein content of 3.0% and a milk fat content of 0.5%;

[0071] B ingredients

[0072] Batch the standardized milk obtained in step A, add 3% white g...

Embodiment 3

[0082] The high-protein yoghurt is prepared from the following raw materials in mass percentage: 4% of white sugar; 0.4% of Lactobacillus bulgaricus; Its specific preparation method comprises the following steps:

[0083] A standardized pretreatment of milk

[0084] Fresh milk is taken and subjected to standardized pretreatment, specifically including skimming standardization and protein standardization, specifically skimming milk by centrifugation technology, and controlling the fat content to 1%. Protein standardization specifically uses a single-effect falling film evaporator to standardize the milk into a milk protein content of 3.2%, thereby standardizing the milk into standardized raw milk with a milk protein content of 3.2% and a milk fat content of 1%;

[0085] B ingredients

[0086] Batch the standardized milk obtained in step A, add 4% white granulated sugar in a shear tank and stir and mix for 20 minutes;

[0087] C. Homogenization

[0088] The material obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com