Preparation method of high surface smoothness polystyrene hollow microspheres

A polystyrene, hollow microsphere technology, applied in the preparation of microspheres, microcapsule preparations, etc., to achieve the effect of small surface roughness, high sphericity, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

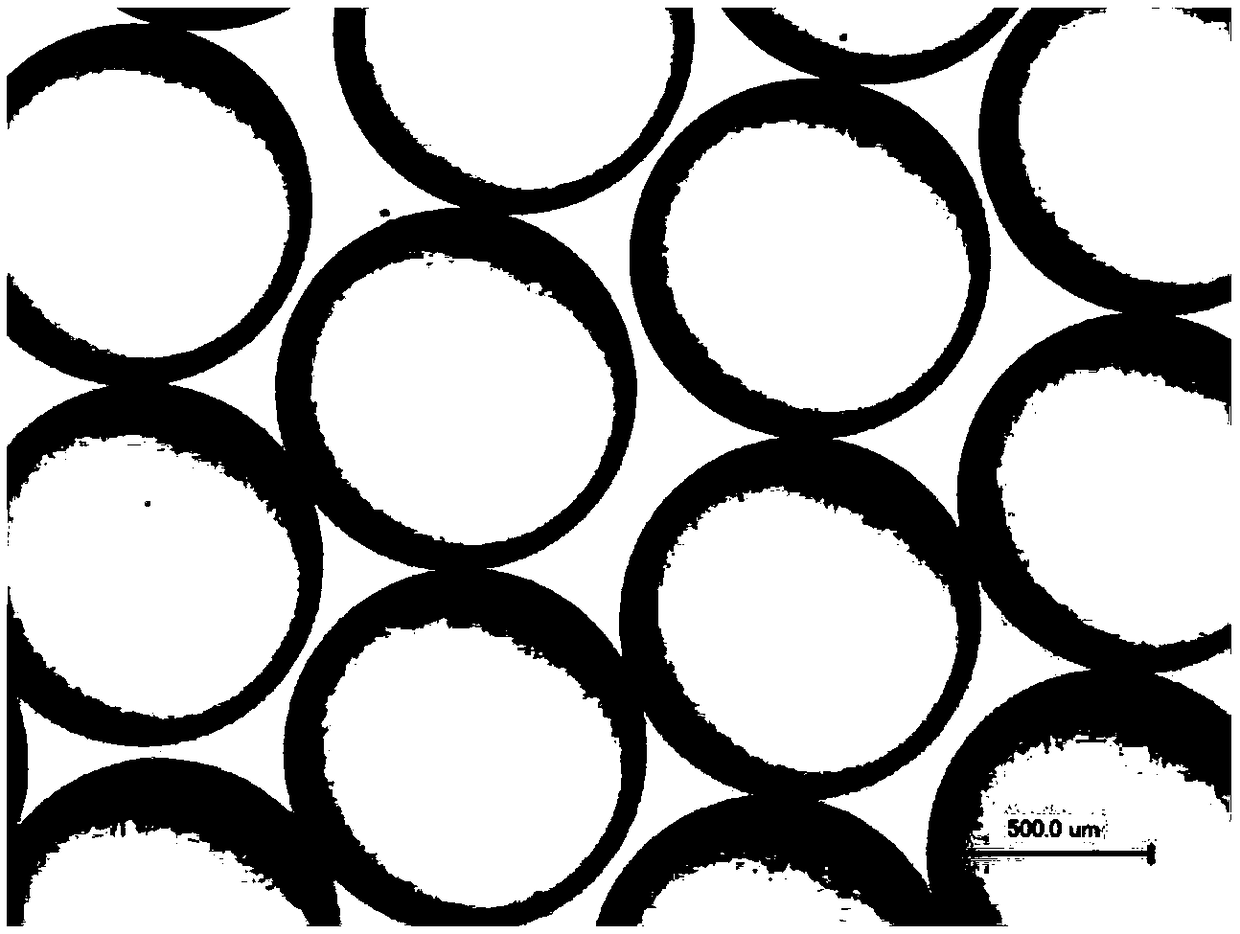

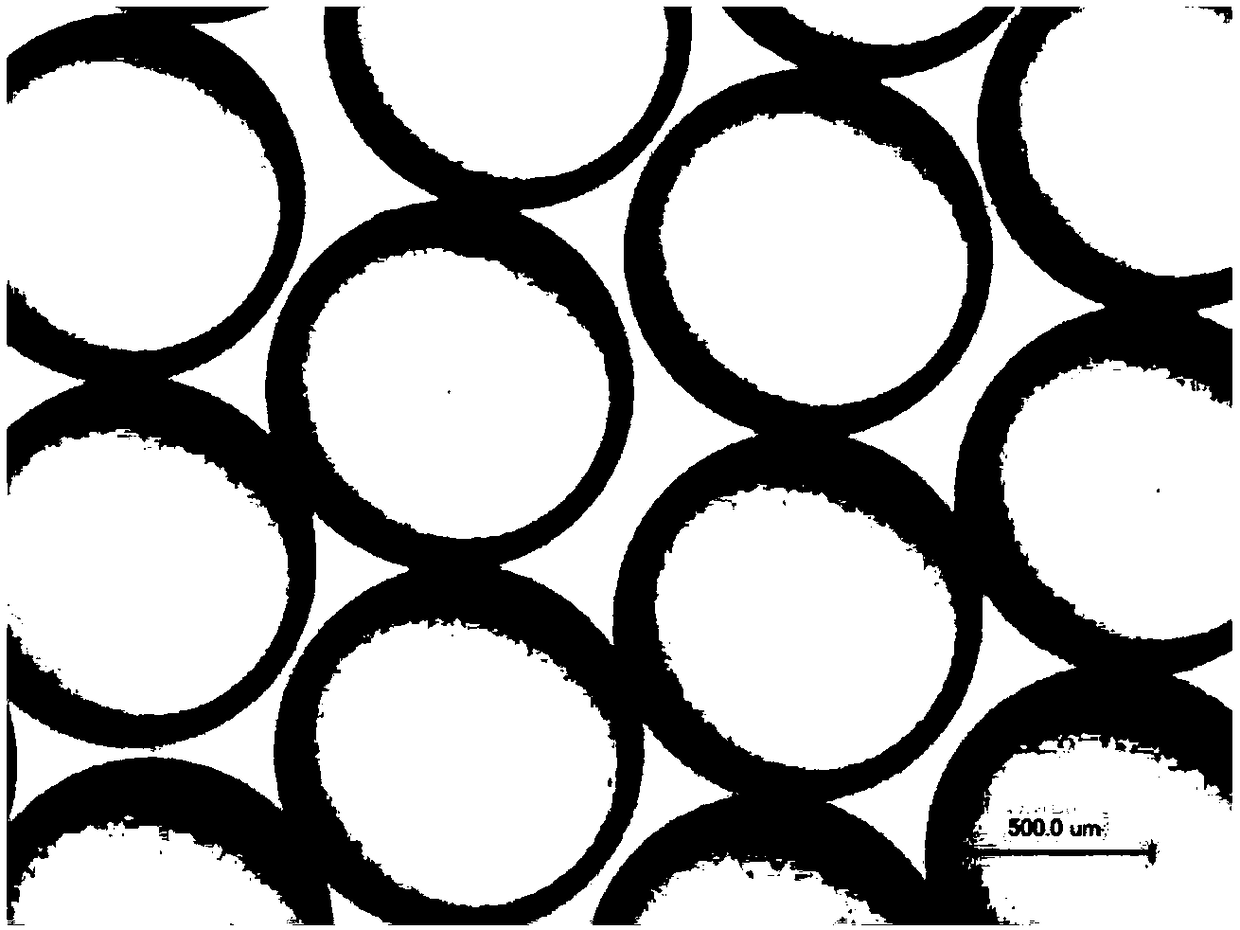

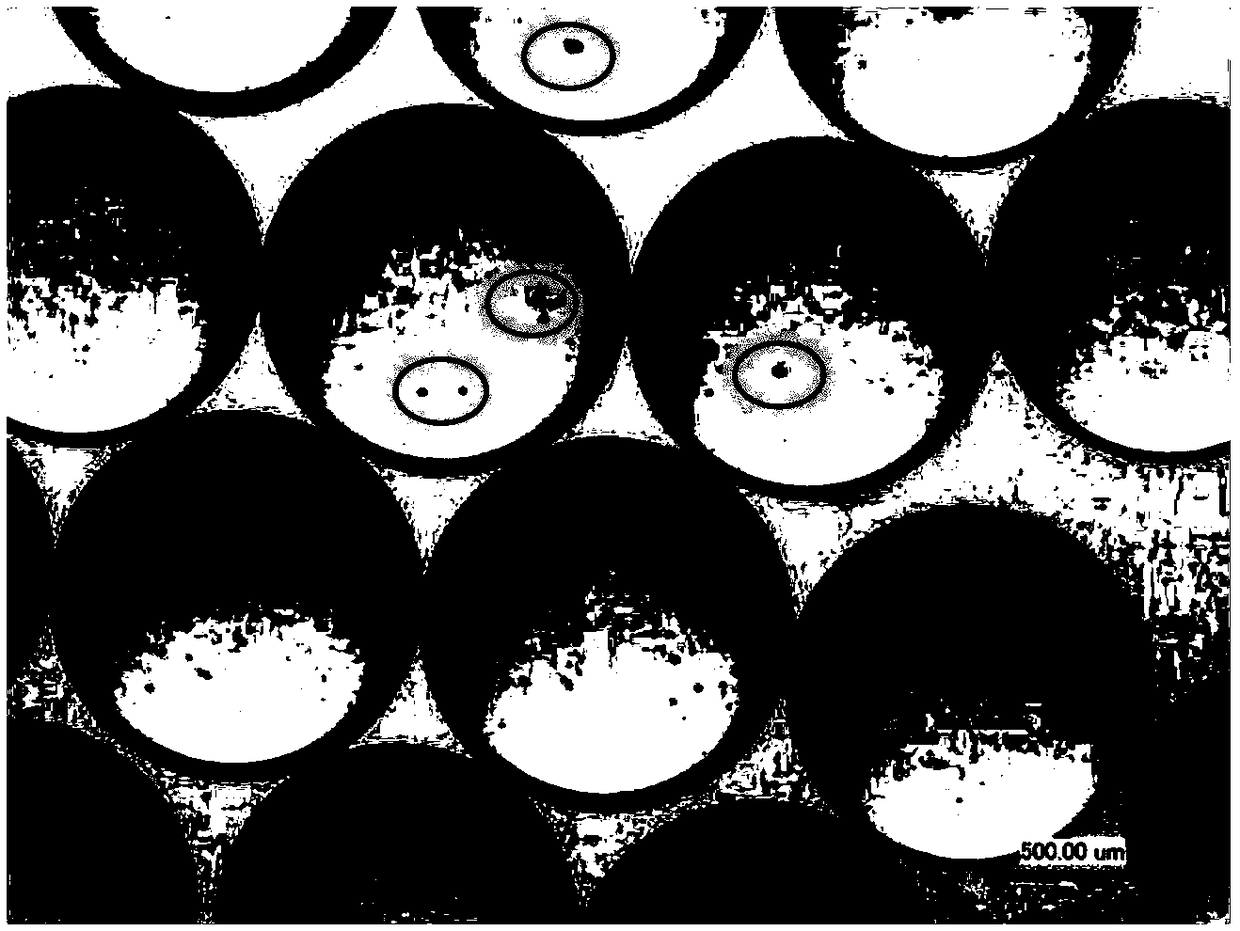

Image

Examples

Embodiment 1

[0033] A preparation method of polystyrene hollow microspheres with high surface smoothness, comprising the following steps:

[0034] Step 1. Purification of raw materials: fluorobenzene water bath with temperature controlled at 85°C, redistilled; heavy water water bath with temperature controlled at 90°C, redistilled; ethanol water bath with temperature controlled at 40°C, redistilled; during redistillation process, glass instruments are surrounded by polytetrafluoroethylene tape Winding and sealing; polystyrene is dissolved in toluene, so that the mass fraction of polystyrene is 10%, add twice the volume of distilled water according to the volume of the solution, and stir for 24 hours; use a separatory funnel to remove the lower layer of water, add twice the volume of distilled water and stir, Repeat 5 times until the upper and lower layers are basically clear after separation; use a separatory funnel to separate the toluene solution in the upper layer, use a 0.2 μm microporo...

Embodiment 2

[0040] A preparation method of polystyrene hollow microspheres with high surface smoothness, comprising the following steps:

[0041] Step 1. Purification of raw materials: fluorobenzene water bath with temperature controlled at 85°C, redistilled; heavy water water bath with temperature controlled at 90°C, redistilled; ethanol water bath with temperature controlled at 40°C, redistilled; during redistillation process, glass instruments are surrounded by polytetrafluoroethylene tape Winding and sealing; polystyrene is dissolved in toluene, so that the mass fraction of polystyrene is 10%, add twice the volume of distilled water according to the volume of the solution, and stir for 24 hours; use a separatory funnel to remove the lower layer of water, add twice the volume of distilled water and stir, Repeat 5 times until the upper and lower layers are basically clear after separation; use a separatory funnel to separate the toluene solution in the upper layer, use a 0.2 μm microporo...

Embodiment 3

[0047] A preparation method of polystyrene hollow microspheres with high surface smoothness, comprising the following steps:

[0048] Step 1. Purification of raw materials: fluorobenzene water bath with temperature controlled at 85°C, redistilled; heavy water water bath with temperature controlled at 90°C, redistilled; ethanol water bath with temperature controlled at 40°C, redistilled; during redistillation process, glass instruments are surrounded by polytetrafluoroethylene tape Winding and sealing; polystyrene is dissolved in toluene, so that the mass fraction of polystyrene is 10%, add twice the volume of distilled water according to the volume of the solution, and stir for 24 hours; use a separatory funnel to remove the lower layer of water, add twice the volume of distilled water and stir, Repeat 5 times until the upper and lower layers are basically clear after separation; use a separatory funnel to separate the toluene solution in the upper layer, use a 0.2 μm microporo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com