Lignin/surfactant composite nanoparticle and preparation method thereof

A technology of composite nanoparticles and surfactants, applied in the field of nanomaterials, can solve the problems of easy agglomeration of lignin nanoparticles, poor water dispersibility, environmental hazards, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

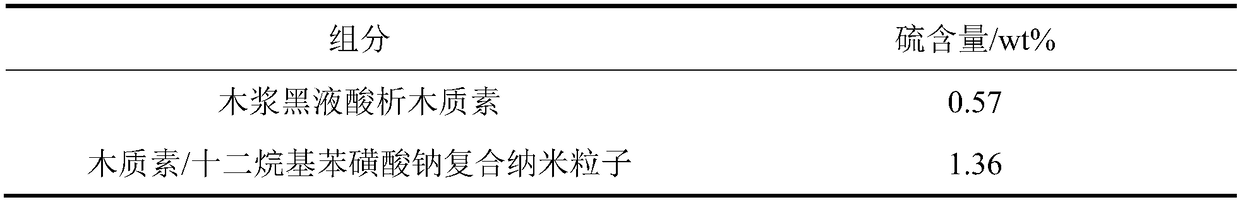

[0037] (1) Take 100 parts by mass of acid-analyzed lignin powder from wood pulp black liquor and use sodium hydroxide to prepare an aqueous solution with a concentration of 20 wt% and a pH of 12, add 15 parts by mass of epichlorohydrin, and crosslink at 95°C After reacting for 2 hours, the reaction liquid was dried by rotary evaporation to obtain high molecular weight lignin.

[0038] (2) Take 1 mass part of the above-mentioned high molecular weight lignin and add it to 100 mass parts of water, add an appropriate amount of sodium hydroxide to adjust the pH of the solution to 9 to completely dissolve the lignin, add 0.4 mass part of sodium dodecylbenzenesulfonate, and continue stirring Sodium dodecylbenzenesulfonate was completely dissolved to obtain a mixed solution.

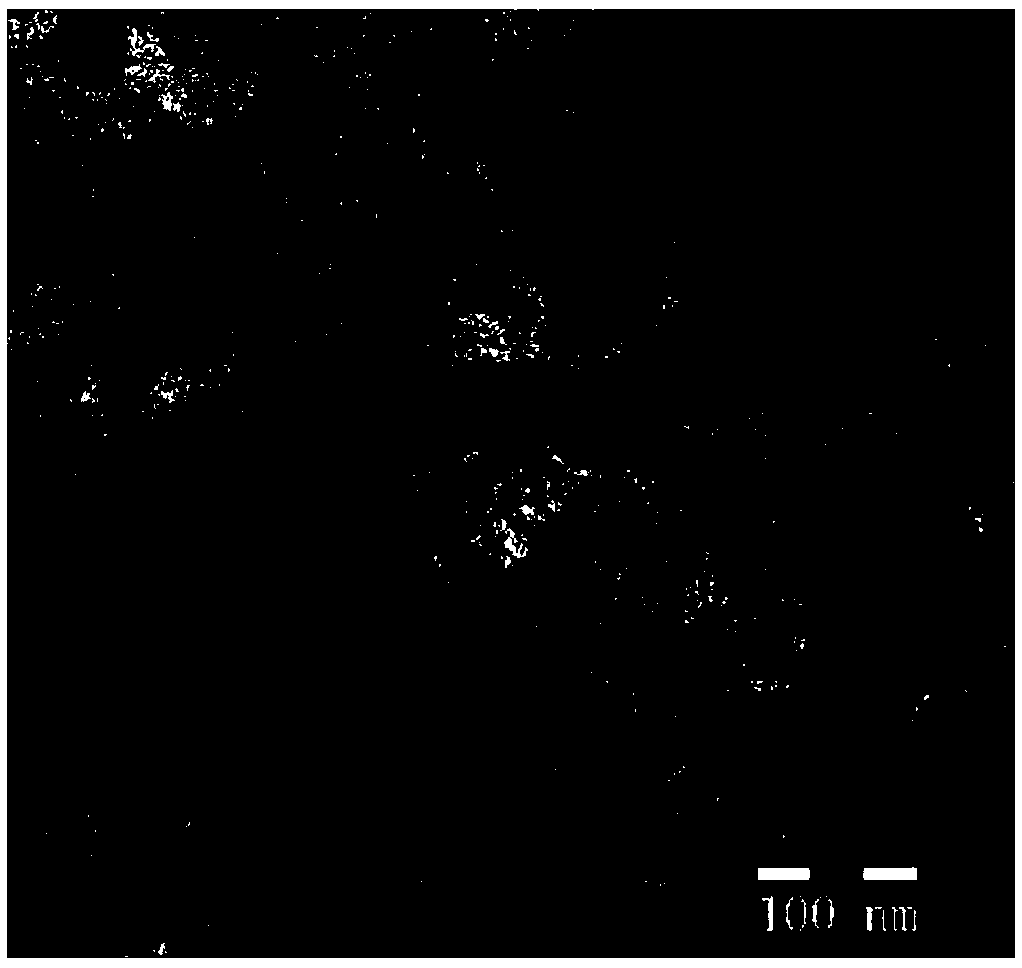

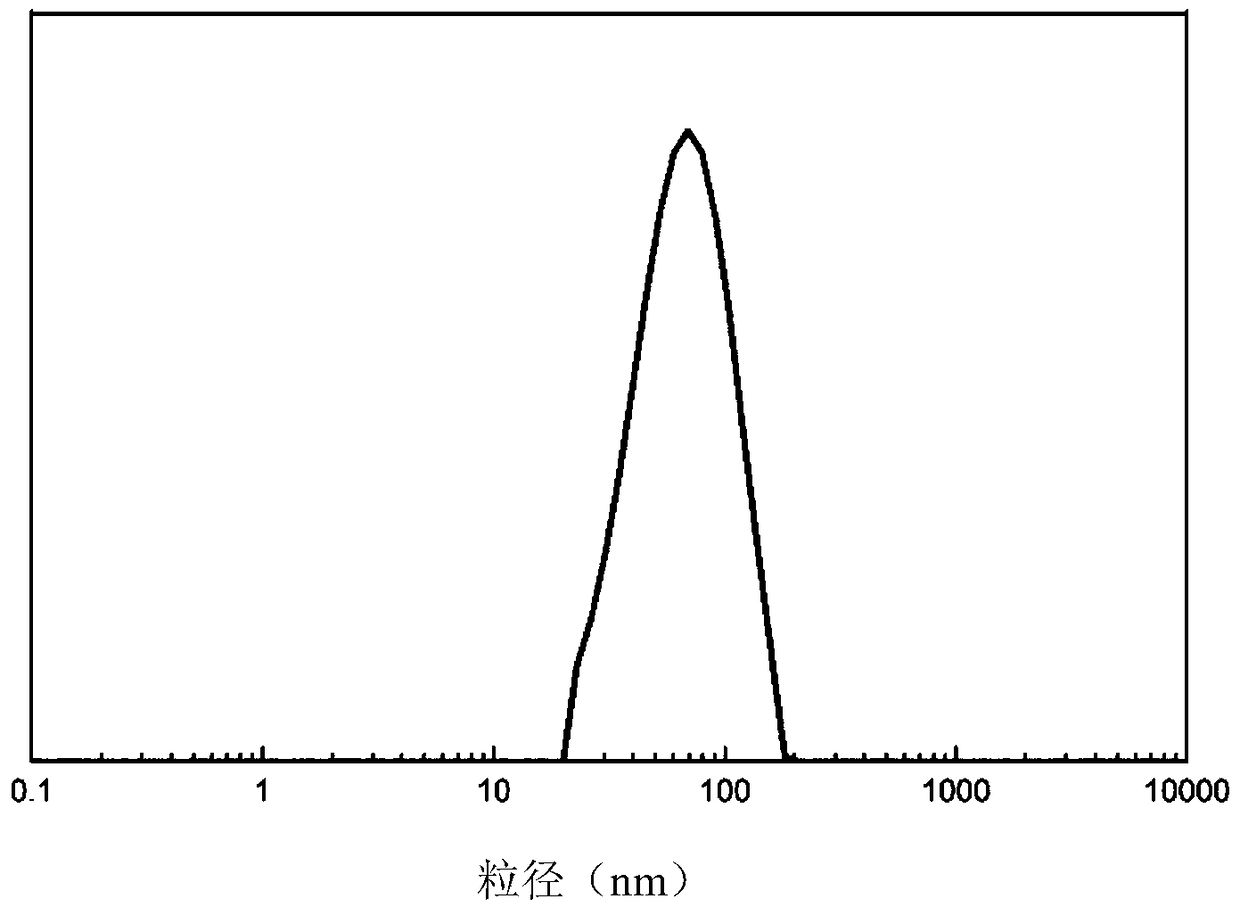

[0039] (3) Add hydrochloric acid dropwise to the above mixed solution until the pH of the solution is 4, and continuously stir to obtain a dispersion of lignin / sodium dodecylbenzenesulfonate composite nanopartic...

Embodiment 2

[0041](1) Take 100 parts by mass of enzymatic lignin and use ammonia water to prepare an aqueous solution with a concentration of 30wt% and a pH of 10, add 20 parts by mass of epichlorohydrin, conduct a crosslinking reaction at 90°C for 2 hours, and dry the reaction solution by rotary evaporation Finally, high molecular weight lignin is obtained.

[0042] (2) Take 0.5 parts by mass of the above-mentioned high molecular weight lignin and add it to 100 parts by mass of water, add an appropriate amount of ammonia water to adjust the pH of the solution to 12 to completely dissolve the lignin, add 0.5 parts by mass of sodium oleate and 0.5 parts by mass of dodecylbenzenesulfonate Sodium Oleate, continue stirring to completely dissolve Sodium Oleate and Sodium Dodecylbenzene Sulfonate to obtain a mixed solution.

[0043] (3) Add sulfuric acid dropwise to the above mixed solution until the pH of the solution is 6, and continuously stir to obtain a dispersion of lignin / sodium oleate-s...

Embodiment 3

[0045] (1) Get 100 mass parts of acid-analyzed lignin powder from bamboo pulp black liquor and use sodium hydroxide to prepare an aqueous solution with a concentration of 40wt% and a pH of 9, add 10 mass parts of epichlorohydrin, and crosslink at 95°C After reacting for 3 hours, the reaction solution was dried by rotary evaporation to obtain high molecular weight lignin.

[0046] (2) Take 5 parts by mass of the above-mentioned high molecular weight lignin and add it to 100 parts by mass of water, add an appropriate amount of sodium hydroxide to adjust the pH of the solution to 11 to completely dissolve the lignin, add 2 parts by mass of sodium oleate, and continue stirring to completely dissolve the sodium oleate Dissolved to obtain a mixed solution.

[0047] (3) Add sulfuric acid dropwise to the above mixed solution until the pH of the solution is 5, and continuously stir to obtain a dispersion of lignin / sodium oleate composite nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com