A kind of graphene/metal lithium composite electrode and preparation method thereof

A composite electrode and graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the size of metal lithium, high internal impedance of the electrode, weakening the role of the matrix skeleton, etc., to inhibit the growth of surface dendrites, The method is simple and easy to operate, and the effect of increasing the composite area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of a graphene / metal lithium composite electrode, comprising:

[0026] A) mixing graphene powder, binder solution and metal lithium powder to obtain graphene-metal lithium powder mixed slurry;

[0027] B) coating the graphene-metal lithium powder mixed slurry to obtain pole pieces;

[0028] C) heating and activating the pole piece to obtain a graphene / metal lithium composite electrode.

[0029] In the present invention, firstly, the graphene powder, the binder solution and the lithium metal powder are mixed to obtain a graphene-lithium metal powder mixed slurry; preferably, the graphene powder and the binder solution are firstly mixed to obtain the mixed slurry.

[0030] Wherein, the binder solution is obtained by dissolving the binder in a solvent, and the binder preferably includes polyvinylidene fluoride; the solvent preferably includes N-methylpyrrolidone.

[0031] The mass fraction of the polyvinylidene fluoride in the b...

Embodiment 1

[0055] Take 2.0 g of PVDF powder, add it into 38 g of NMP solution, and stir the above solution until PVDF is completely dissolved to obtain a PVDF / NMP solution with a mass fraction of 5%. Weigh 0.05 g of graphene powder below 20 microns into a reagent bottle, add 2.0 g of the above solution, then transfer the reagent bottle to a glove box, and stir for 12 hours in an argon protective atmosphere. Then weigh 0.35g of metal lithium powder with a thickness of less than 50 microns, slowly add it into the above solution, and continue stirring at the same time to obtain a uniform graphene / metal lithium powder slurry.

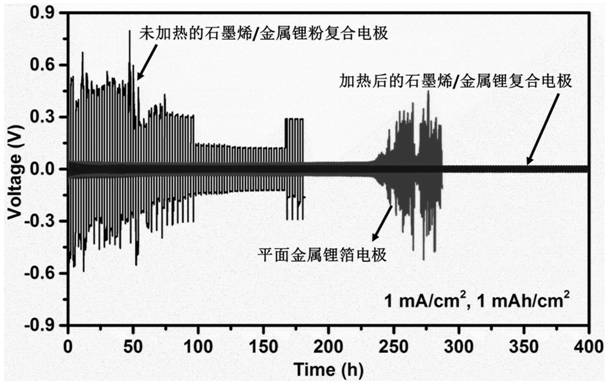

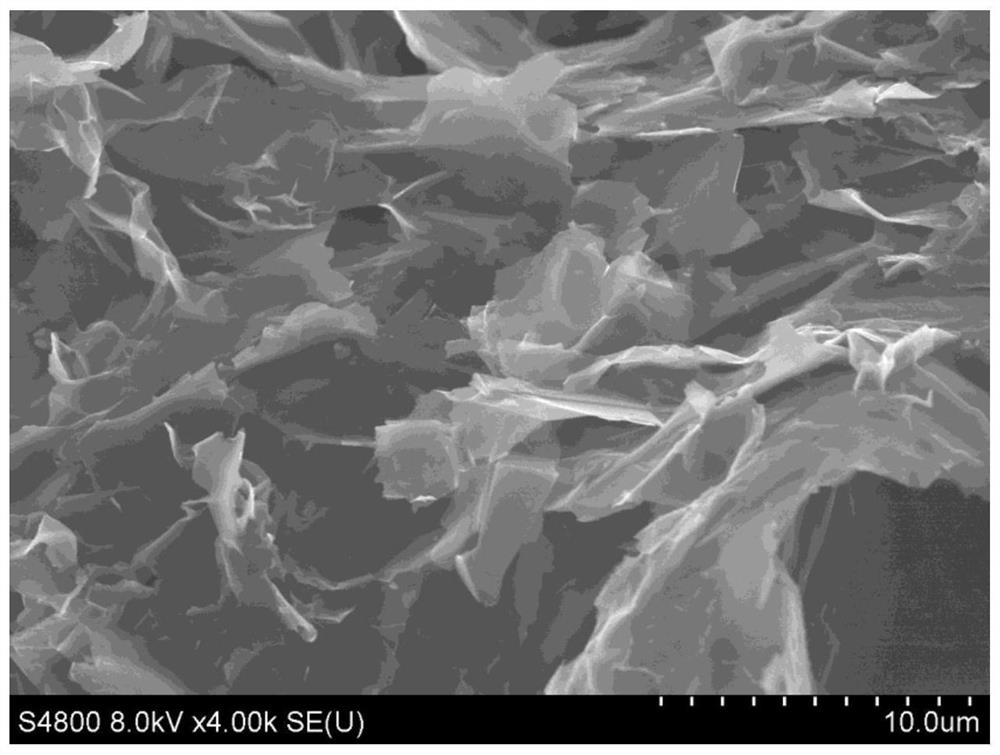

[0056] The above slurry was coated in a glove box, copper foil was used as a current collector, and a 250 μm thick scraper was used to scrape the sample, and then the sample was placed in an argon protective atmosphere and dried naturally to obtain a 200 μm thick pole piece. The shape of the pole piece was measured, and the results were as follows: figure 1 as shown,...

Embodiment 2

[0060] Take 2.0 g of PVDF powder, add it into 38 g of NMP solution, and stir the above solution until PVDF is completely dissolved to obtain a PVDF / NMP solution with a mass fraction of 5%. Weigh 0.035g of graphene powder below 15 microns into a reagent bottle, add 2g of the above solution, and then add 1.5g of NMP solution, then transfer the reagent bottle to a glove box, and stir for 12h in an argon atmosphere. Then weigh 0.815g of metal lithium powder below 40 microns, slowly add it into the above solution, and continue stirring at the same time to obtain a uniform graphene / metal lithium powder slurry.

[0061] The above slurry was coated in a glove box, copper foil was used as a current collector, and a 200 μm thick scraper was used to scrape the sample, and then the sample was placed in an argon protective atmosphere and dried naturally to obtain a 150 μm thick pole piece.

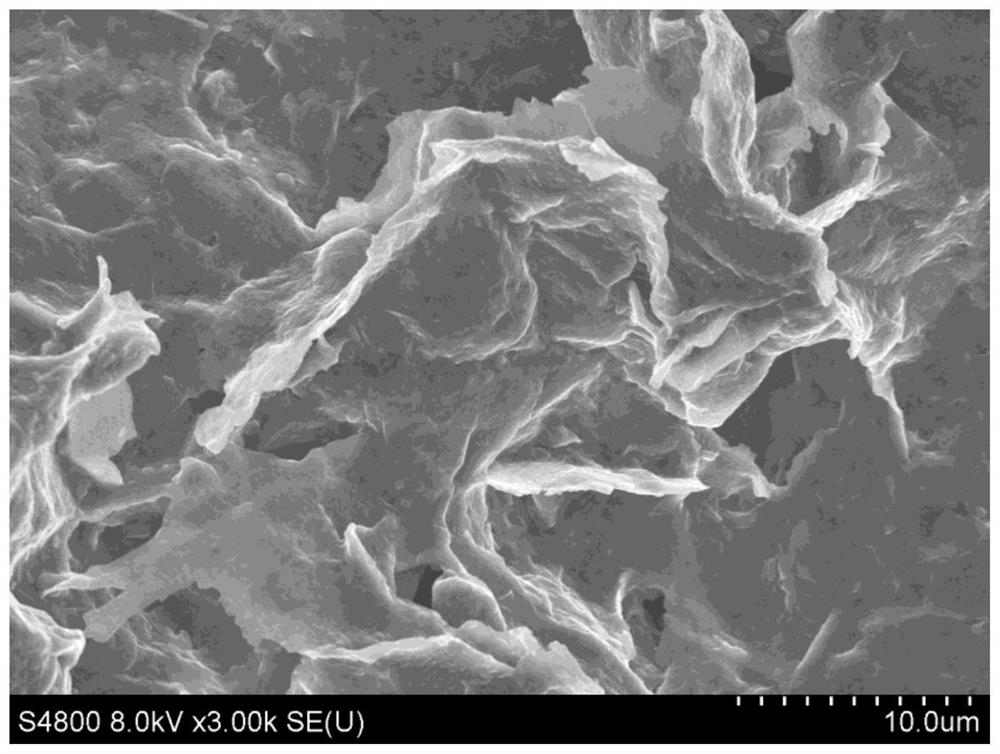

[0062] After the drying is complete, the pole piece is cut out with a puncher, and then the pole pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com