A kind of surface nickel phosphate modified titanium dioxide photocatalyst and its preparation method and application

A technology of titanium dioxide and photocatalyst, which is applied in the field of photocatalysis to achieve the effect of easy-to-obtain raw materials, simple preparation method and remarkable catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

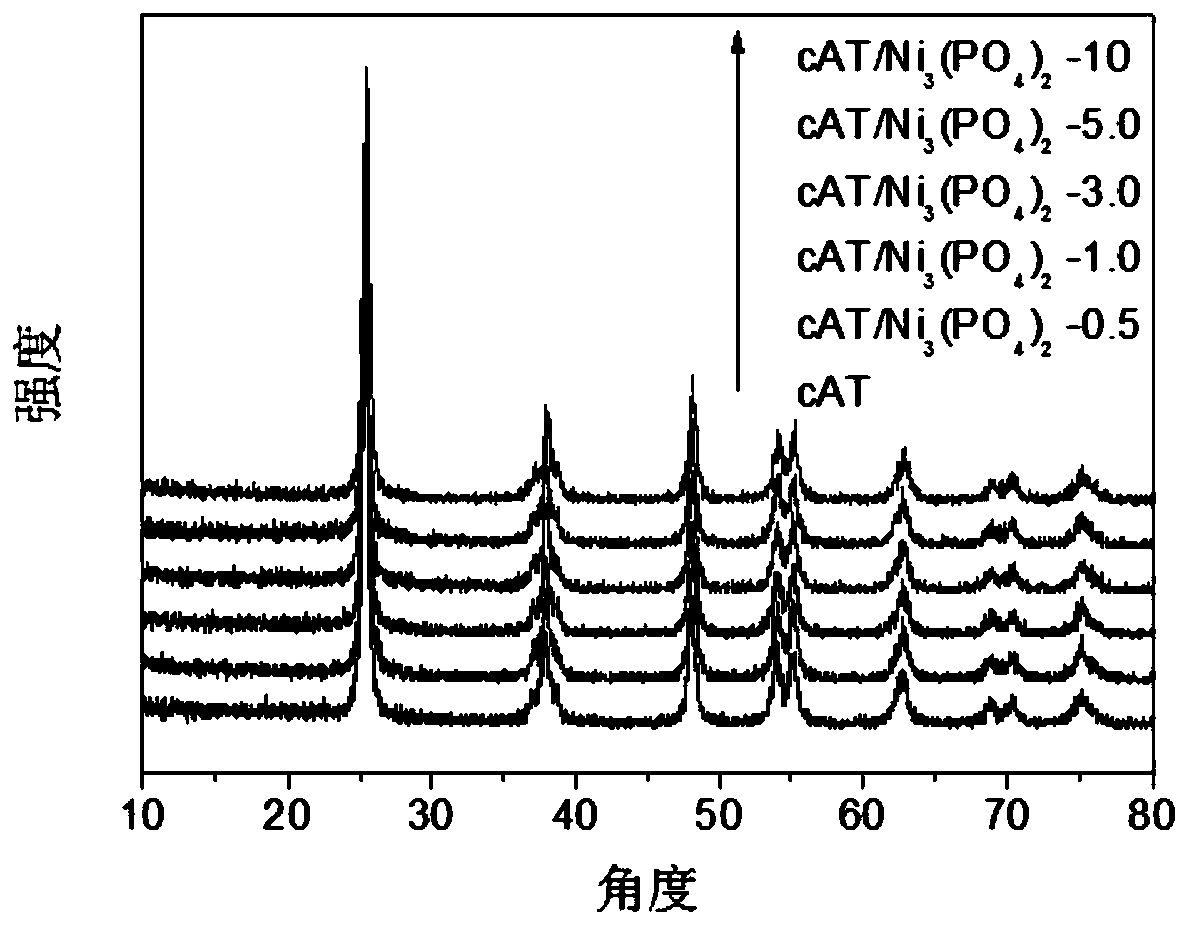

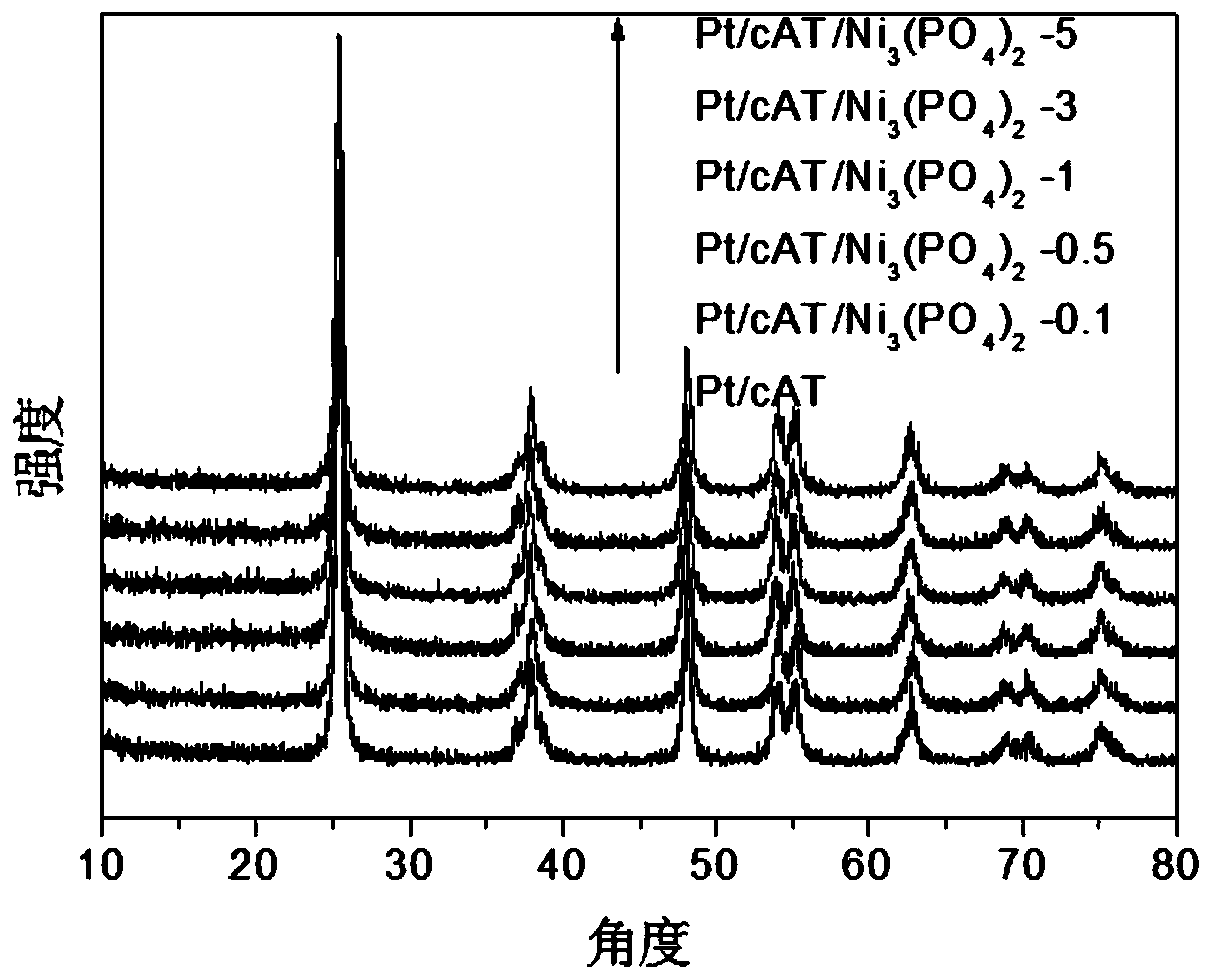

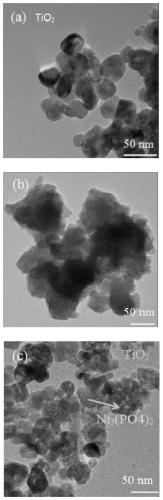

[0042] The preparation method of the present invention is an ice bath deposition method. The specific measures are as follows: use commercial titanium dioxide as a semiconductor photocatalyst, use nickel salt as a nickel source, and use water as a solvent to adsorb nickel ions in the solution on the surface of the titanium dioxide. Then nickel ions were immobilized on the surface of titanium dioxide in the form of nickel phosphate with sodium phosphate under the condition of ice bath. Filter, wash and dry to obtain the surface nickel phosphate-modified titanium dioxide photocatalyst. This process does not change the physical properties of titanium dioxide itself such as crystallinity, crystal phase composition, average particle size, pore structure and specific surface area.

[0043] Compared with the traditional modification method, the method is simple to operate, easy to control the process, and has high repeatability.

Embodiment 1

[0045] Step 1: Weigh 0.2 g of commercial anatase, put it into 50 mL of deionized water, and ultrasonically disperse it for 5 minutes to obtain material A1.

[0046] Step 2, at room temperature, pipette 0.18mL of 50mM nickel perchlorate solution, put it into the suspension A1 obtained in step 1, and stir evenly for 2 hours in a dark state to obtain material B1;

[0047] Step 3: Add 2.5M sodium phosphate solution dropwise to the suspension B1 obtained in step 2 under ice bath conditions, and add excess sodium phosphate solution dropwise to obtain material C1 with light green precipitate.

[0048] In step four, the material C1 obtained in step three was washed and dried several times, and dried in an oven at 60° C. for 12 hours to obtain composite photocatalyst D1.

Embodiment 2

[0050] Step 1: Weigh 0.2 g of commercial anatase, put it into 50 mL of deionized water, and ultrasonically disperse it for 5 minutes to obtain material A2.

[0051] Step 2, at room temperature, pipette 0.36mL 50mM nickel perchlorate solution, put it into the suspension A2 obtained in step 1, and stir evenly for 2 hours in a dark state to obtain material B2;

[0052] Step 3: Add 2.5M sodium phosphate solution dropwise to the suspension B2 obtained in step 2 under ice bath conditions, and add excess sodium phosphate solution dropwise to obtain material C2 with light green precipitate.

[0053] In step four, the material C2 obtained in step three was washed and dried several times, and dried in an oven at 60° C. for 12 hours to obtain composite photocatalyst D2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com