Double-protein fermented milk beverage rich in active Lactobacillus plantarum and preparation method thereof

A technology of Lactobacillus plantarum and fermented milk, which is applied to Lactobacillus, bacteria used in food preparation, dairy products, etc., can solve the problem of lack of probiotic characteristics and flavor homogeneity, low concentration of Lactobacillus plantarum live bacteria, and influence of dairy flavor. and other problems to achieve the effect of shortening fermentation time, facilitating absorption and utilization, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Specific steps are as follows:

[0060] (1) Accurately weigh 24.00g skimmed milk powder, 4.00g soybean protein isolate, 1.00g soybean peptone, 0.0004g manganese citrate (12% skim milk powder, 2% soybean protein, 0.5% soybean peptone, 0.0002% manganese citrate ), add purified water to it to measure to 200g, after dissolving, homogenize the emulsion under the condition of 4000r / min, sterilize at 90°C for 15min, cool to 37°C, and obtain the double protein fermentation base material;

[0061] (2) The lyophilized powder of Lactobacillus plantarum CGMCC No.6077 was mixed with 1×10 7 The inoculum amount of cfu / g is added to the fermentation base material under aseptic conditions, and the inoculated fermentation base material is placed in a constant temperature incubator at 37°C for fermentation to obtain fermented milk;

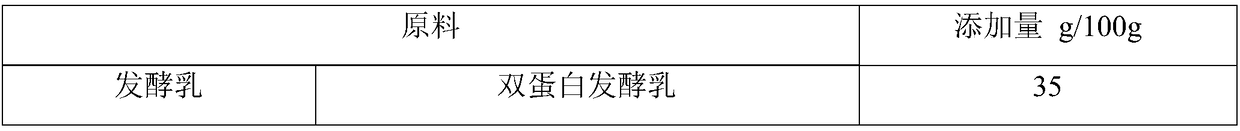

[0062] (3) Stabilizers, sweeteners and flavors were mixed according to the ratio in Table 1, added to pure water preheated to 90°C, stirred quickly, mixed e...

Embodiment 2

[0071] Specific steps are as follows:

[0072] (1) Accurately weigh 24.00g skimmed milk powder, 4.00g soybean protein isolate, 1.00g debittered soybean peptide, 0.0004g manganese citrate (skimmed milk powder 12%, soybean protein 2%, debittered soybean peptide 0.5%, lemon Manganese acid manganese acid 0.0002%), add pure water therein and quantify to 200g, after dissolving, the emulsion is homogenized under the condition of 4000r / min, sterilized at 90°C for 15min, cooled to 37°C, to obtain the double protein fermentation base material;

[0073] (2) The lyophilized powder of Lactobacillus plantarum CGMCC No.5494 was mixed with 1×10 7 The inoculum amount of cfu / g is added to the fermentation base material under aseptic conditions, and the inoculated fermentation base material is placed in a constant temperature incubator at 37°C for fermentation to obtain fermented milk;

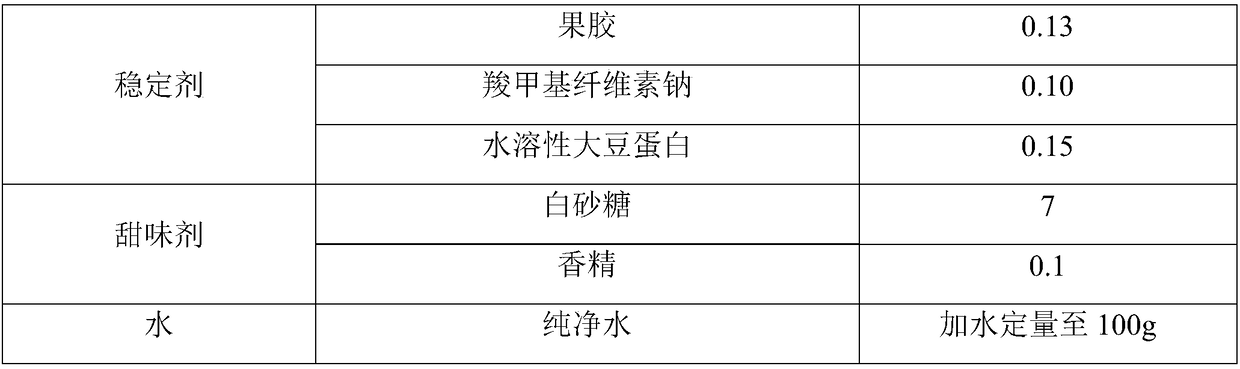

[0074] (3) Stabilizers, sweeteners and flavors were mixed according to the ratio in Table 3, added to purifi...

Embodiment 3

[0082] Specific steps are as follows:

[0083] (1) Accurately weigh 24.00g skimmed milk powder, 4.00g soybean protein isolate, 1.00g casein hydrolyzate, 0.0004g manganese citrate (skim milk powder 12%, soybean protein 2%, casein hydrolyzate 0.5%, lemon Manganese acid manganese acid 0.0002%), add pure water therein and quantify to 200g, after dissolving, the emulsion is homogenized under the condition of 4000r / min, sterilized at 90°C for 15min, cooled to 37°C, to obtain the double protein fermentation base material;

[0084] (2) The lyophilized powder of Lactobacillus plantarum CCTCCM 206032 was mixed with 6×10 6 cfu / g is added to the fermentation base material under aseptic conditions, and the inoculated fermentation base material is placed in a constant temperature incubator at 37°C for fermentation to obtain fermented milk;

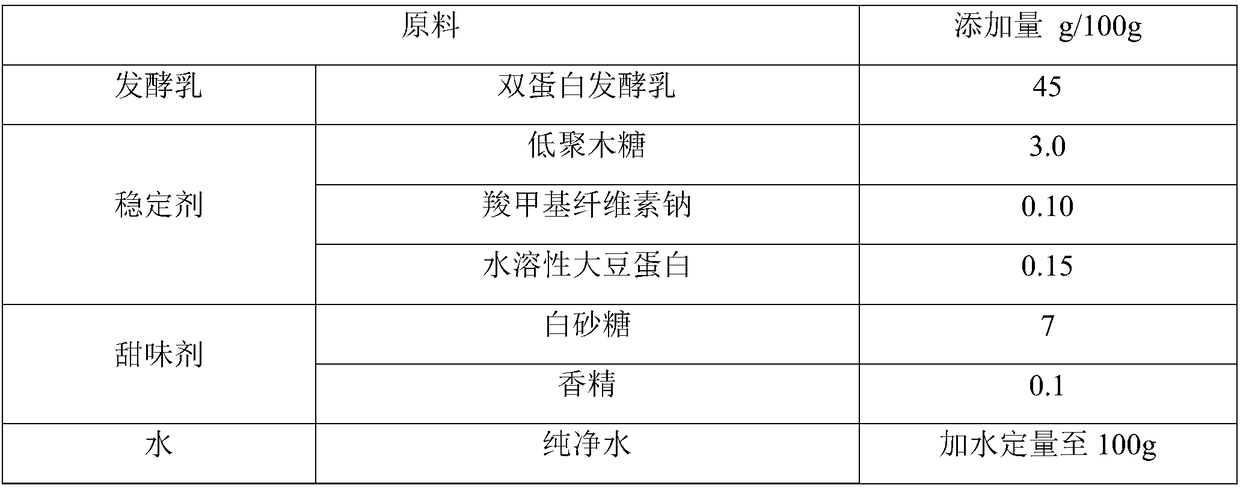

[0085] (3) Stabilizers, sweeteners and flavors were mixed according to the ratio in Table 4, added to purified water preheated to 90°C, stirred quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com