A preparing method of a Cu2S/g-C3N4 heterojunction photocatalyst

A photocatalyst, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult operation, complex reaction raw materials, etc., to achieve environmental pollution-free, easy-to-use raw materials , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

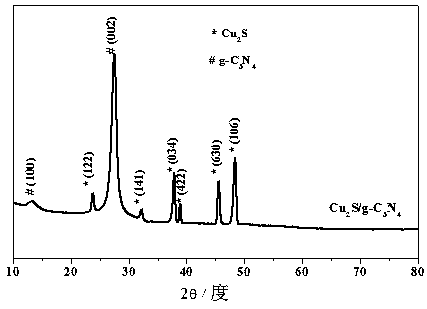

[0022] a Cu 2 S / g-C 3 N 4 The preparation method of heterojunction photocatalyst, concrete steps are as follows:

[0023] Mix 10g of cuprous thiocyanate with 0.5g of ammonium chloride, grind the mixture evenly, place it in a tube furnace, and calcinate it at 400°C for 3 hours in a nitrogen atmosphere, wash the obtained product with distilled water and dry it to obtain Cu 2 S / g-C 3 N 4 heterojunction photocatalysts.

Embodiment 2

[0025] a Cu 2 S / g-C 3 N 4 The preparation method of heterojunction photocatalyst, concrete steps are as follows:

[0026] Mix 12g of cuprous thiocyanate with 0.5g of ammonium chloride, grind the mixture evenly, place it in a tube furnace, and calcinate it at 450°C for 4 hours in a nitrogen atmosphere, wash the obtained product with distilled water and dry it to obtain Cu 2 S / g-C 3 N 4 heterojunction photocatalysts.

Embodiment 3

[0028] a Cu 2 S / g-C 3 N 4 The preparation method of heterojunction photocatalyst, concrete steps are as follows:

[0029] Mix 15g of cuprous thiocyanate with 0.6g of ammonium chloride, grind the mixture evenly, place it in a tube furnace, and calcinate it at 500°C for 4 hours in a nitrogen atmosphere, wash the obtained product with distilled water and dry it to obtain Cu 2 S / g-C 3 N 4 heterojunction photocatalysts.

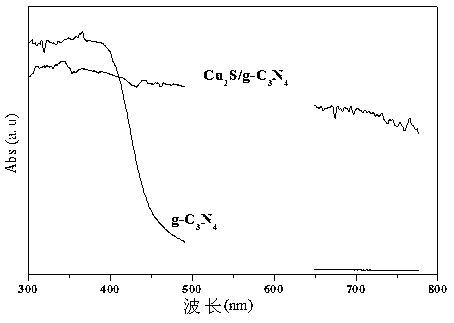

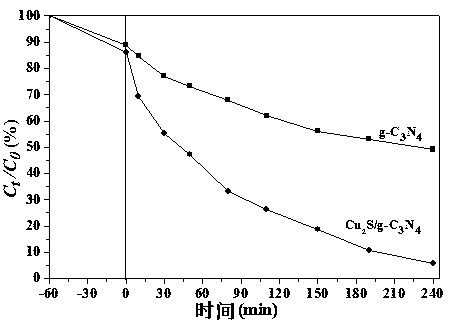

[0030] In order to compare the catalytic activity of the catalyst prepared by the present invention, hereinafter in this description, pure g-C 3 N 4 It is obtained through the following process: put 15g of melamine in a tube furnace and calcinate it at 500°C for 4h, and the product obtained is marked as g-C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com