Preparation method of C1 doped glucose carbon based graphene

A technology of glucose and graphene, applied in graphene, nano-carbon, coating and other directions, can solve the problems of loss of graphene performance, safety of chemical reagents, many graphene defects, etc. Simple and safe, the process is easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

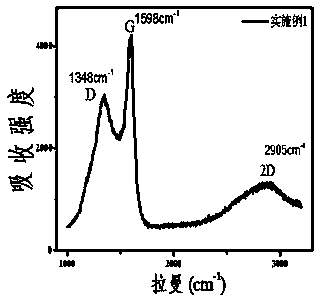

Embodiment 1

[0027] A preparation method of Cl-doped glucose carbon-based graphene, specifically related to the preparation of Cl-doped precursor solution, spin-coated film preparation and annealing process, the specific steps are as follows:

[0028] (1) According to the atomic ratio of C in glucose and Cl in hydrochloric acid of 9:1, mix glucose with hydrochloric acid with a concentration of 1mol / L, and place the mixed solution under stirring conditions at 100°C in the atmospheric environment Boil until the solution viscosity is 1×10 5 Centipoise, the stirring is to stir at a rotating speed of 1500r / min for 30min, as the solution viscosity increases after boiling, then stir at a rotating speed of 800r / min for 30min, and then stir at a rotating speed of 300r / min until the end, and deionized water, The water ethanol and the boiled caramel solution are mixed according to the volume ratio of 1:1:2 and then filtered. The filter is filtered with a filter tip with a pore size of 0.1 μm, and the...

Embodiment 2

[0033] A preparation method of Cl-doped glucose carbon-based graphene, specifically related to the preparation of Cl-doped precursor solution, spin-coated film preparation and annealing process, the specific steps are as follows:

[0034] (1) According to the atomic ratio of C in glucose and Cl in hydrochloric acid of 5:1, mix glucose with hydrochloric acid with a concentration of 1.5mol / L, and place the mixed solution under stirring conditions at 150°C in the atmospheric environment Boil down until the solution viscosity is 1×10 6 Centipoise, stirring is to stir with the rotating speed of 1200r / min for 35min, as the viscosity of the solution increases after boiling, then stir with the rotating speed of 600r / min for 35min, then stir with the rotating speed of 300r / min to the end, mix deionized water, The water ethanol and the boiled caramel solution are mixed according to the volume ratio of 1:1:2.5 and then filtered. The filter is filtered with a filter tip with a pore size o...

Embodiment 3

[0039] A preparation method of Cl-doped glucose carbon-based graphene, specifically related to the preparation of Cl-doped precursor solution, spin-coated film preparation and annealing process, the specific steps are as follows:

[0040] (1) According to the atomic ratio of C in glucose and Cl in hydrochloric acid of 3:1, mix glucose with hydrochloric acid with a concentration of 2mol / L, and place the mixed solution under stirring conditions at 200°C in the atmospheric environment Boil until the solution viscosity is 1×10 6Centipoise, stirring at a speed of 1000r / min for 40min, as the viscosity of the solution increases after boiling, then stirring at a speed of 500r / min for 40min, and then stirring at a speed of 300r / min until the end, the deionized water , absolute ethanol, and the boiled caramel solution are mixed according to a volume ratio of 1:1:3 and then filtered. The filter is filtered using a filter tip with a pore size of 0.3 μm, and the filtrate is a precursor sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com