Alcohol-based fuel and preparation method thereof

A technology of alcohol-based fuel and methanol, which is applied in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of toxic and harmful substances and insufficient combustion of alcohol-based fuels, and achieve the reduction of pollutants, extension of spontaneous combustion induction period, increase The effect of oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

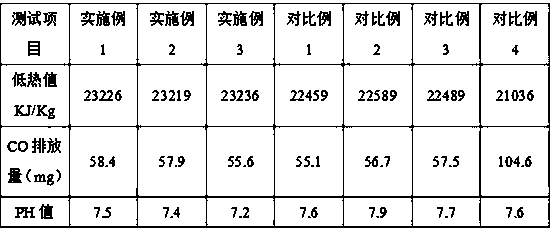

Examples

preparation example Construction

[0029] A preparation method of alcohol-based fuel, comprising the steps of:

[0030]According to the number of parts by mass, take 60~90 parts of methanol, 2~5 parts of ethanol, 3~6 parts of catalytic active agent, 1~3 parts of antiknock additive, 2~5 parts of oxygen-containing blending agent, 8~15 parts of petroleum ether 1~3 parts of 2-methoxyethyl acetate were stirred and mixed for 3~5 hours, and left to stand for 10~12 hours to obtain alcohol-based fuel.

Embodiment 1

[0032] Catalytic active agent: (1) Take AEO-3 and add n-octane at a mass ratio of 1:6, stir and mix for 20 minutes to obtain a mixture, take cerous nitrate and add methanol and formamide at a mass ratio of 2:6:3, and then add nitric acid 40% of the cerium mass fraction is 20% sodium hydroxide solution, stirred and mixed for 30 minutes to obtain mixture a;

[0033] (2) Take the mixture and add it dropwise to mixture a according to the mass ratio of 3:2, control the dropping time for 30 minutes, introduce oxygen, stir and mix at 20°C for 54 hours to obtain a stirred mixture, take the stirred mixture and add acetone according to the mass ratio of 10:3 , Let stand for 3h, centrifuge, take the precipitate, wash with methanol, and dry to obtain the catalytic active agent.

[0034] Anti-knock additive: take o-cresol and add diethylenetriamine at a mass ratio of 1:3, pass through nitrogen protection, heat up to 60°C and stir and mix for 50 minutes, then add dropwise 80% of the mass fr...

Embodiment 2

[0040] Catalytic active agent: (1) Take AEO-3 and add n-octane at a mass ratio of 2:7, stir and mix for 25 minutes to obtain a mixture, take cerous nitrate and add methanol and formamide at a mass ratio of 3:7:5, and then add nitric acid 45% of the cerium mass fraction is 20% sodium hydroxide solution, stirred and mixed for 35min to obtain mixture a;

[0041] (2) Take the mixture and add it dropwise to mixture a according to the mass ratio of 6:4, control the dropping time for 35 minutes, feed oxygen, stir and mix at 23°C for 60 hours to obtain a stirred mixture, take the stirred mixture and add acetone according to the mass ratio of 13:5 , Let it stand for 4h, centrifuge, take the precipitate, wash it with methanol, and dry it to obtain the catalytic active agent.

[0042] Anti-knock additive: take o-cresol and add diethylenetriamine at a mass ratio of 2:5, pass through nitrogen protection, heat up to 70°C and stir and mix for 55 minutes, then add dropwise diethylenetriamine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com