Method for preparing oxygen vacancy-containing bismuth tungstate ultrathin sheet, and oxygen vacancy-containing bismuth tungstate ultrathin sheet and application thereof

A technology of bismuth tungstate and ultra-thin slices, which can be used in separation methods, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve problems such as light waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]0.165g sodium tungstate dihydrate (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%), 0.485g bismuth nitrate pentahydrate (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%) and 10mg potassium bromide (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%) were dissolved in 40mL deionized water and 500 μL concentrated nitric acid (Sinopharm Chemical Reagent Co., Ltd., concentration 67% by mass) mixed solution in turn, placed on an electric heating mantle stirrer (Shanghai Meiyingpu Instrument Co., Ltd. After stirring for 30 minutes at 200r / min from Instrument Manufacturing Co., Ltd. (08-2T), transfer the resulting mixture into a 50mL autoclave, seal it, and put it into an oven (Shanghai Jinghong Experimental Equipment Co., Ltd. XMTD-8222) to react at 120°C for 24h . After the reaction was completed, it was naturally cooled to room temperature, and centrifuged at a speed of 10,000 rpm in a high-speed centrifuge (Anhui Zhongke Zhongjia Scientific Instrument Co., Ltd. HC-35...

Embodiment 2

[0042] 200 mg of Bi without oxygen vacancies synthesized 2 WO 6 The ultra-thin slices are evenly spread on the bottom of the quartz boat, placed on the downstream end (left) of the gas flow of the double-chamber tube furnace (Kojing OTF-1200X-Ⅱ), and placed at the upstream position (right) about 10 cm away from it Another quartz boat contains 15-20 g of aluminum powder (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%). Set the heating program so that the left part of the double-chamber tube furnace is kept at 300 °C, and the right part is kept at 700 °C for 2 hours. Create a simulated vacuum environment by connecting the continuous work of the vacuum pump, and start the heating program of the tube furnace at the same time. After natural cooling, the samples were washed several times with water and ethanol, and dried in vacuum for later use.

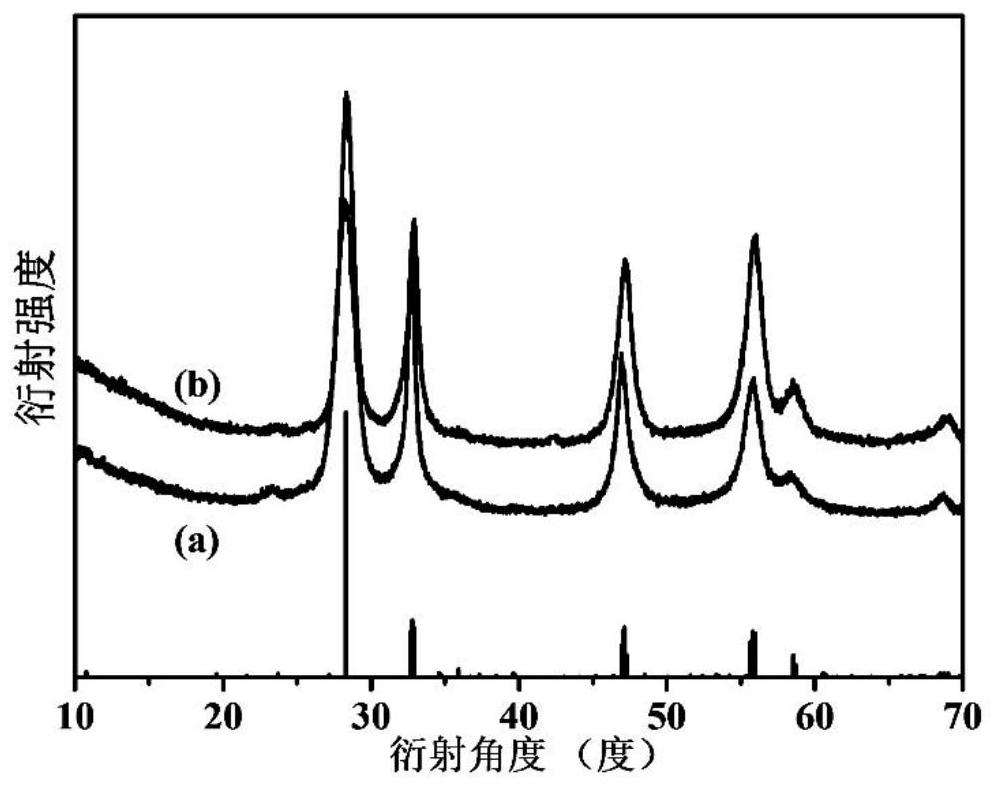

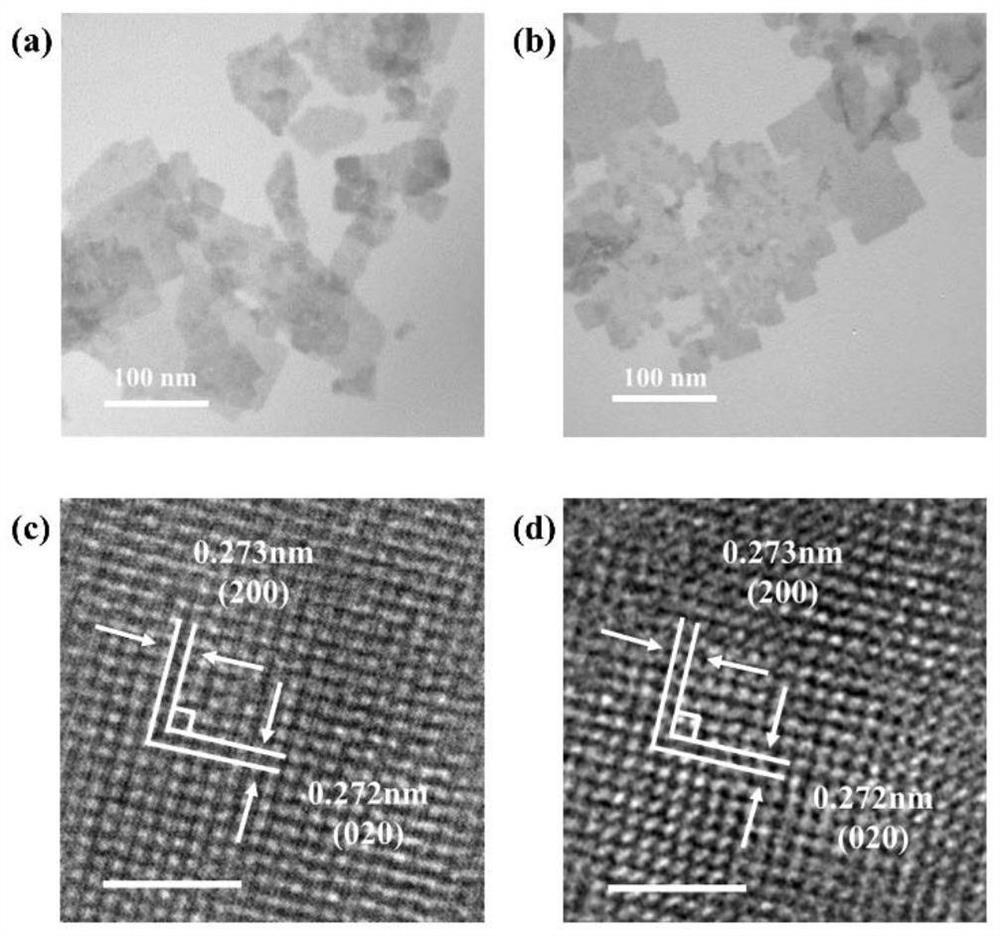

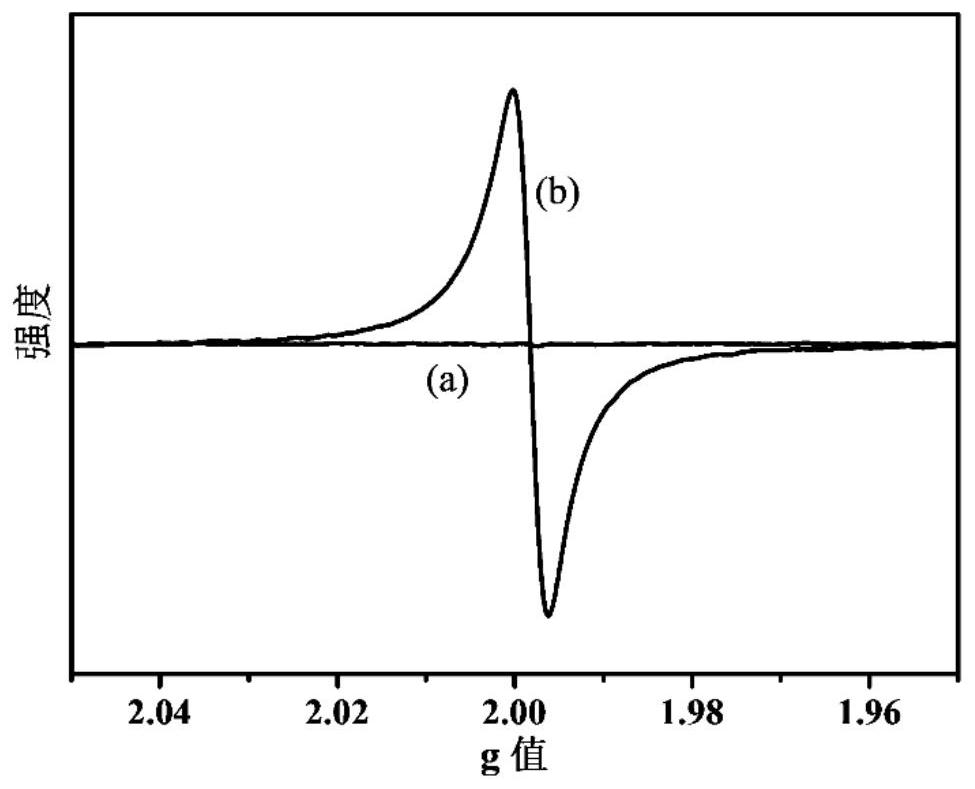

[0043] The flake product was respectively used XRD instrument (Philips X'Pert Pro Super diffractometer), transmission electron mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com