Preparation method of sulfur autotrophic denitrification bacterium immobilized particles

A denitrifying bacteria, sulfur autotrophic technology, applied in biochemical equipment and methods, microorganism-based methods, immobilized on/in organic carriers, etc., can solve the problems of low efficiency, easy loss of free bacteria, etc. Wide range of sources, favorable for adhesion, density-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

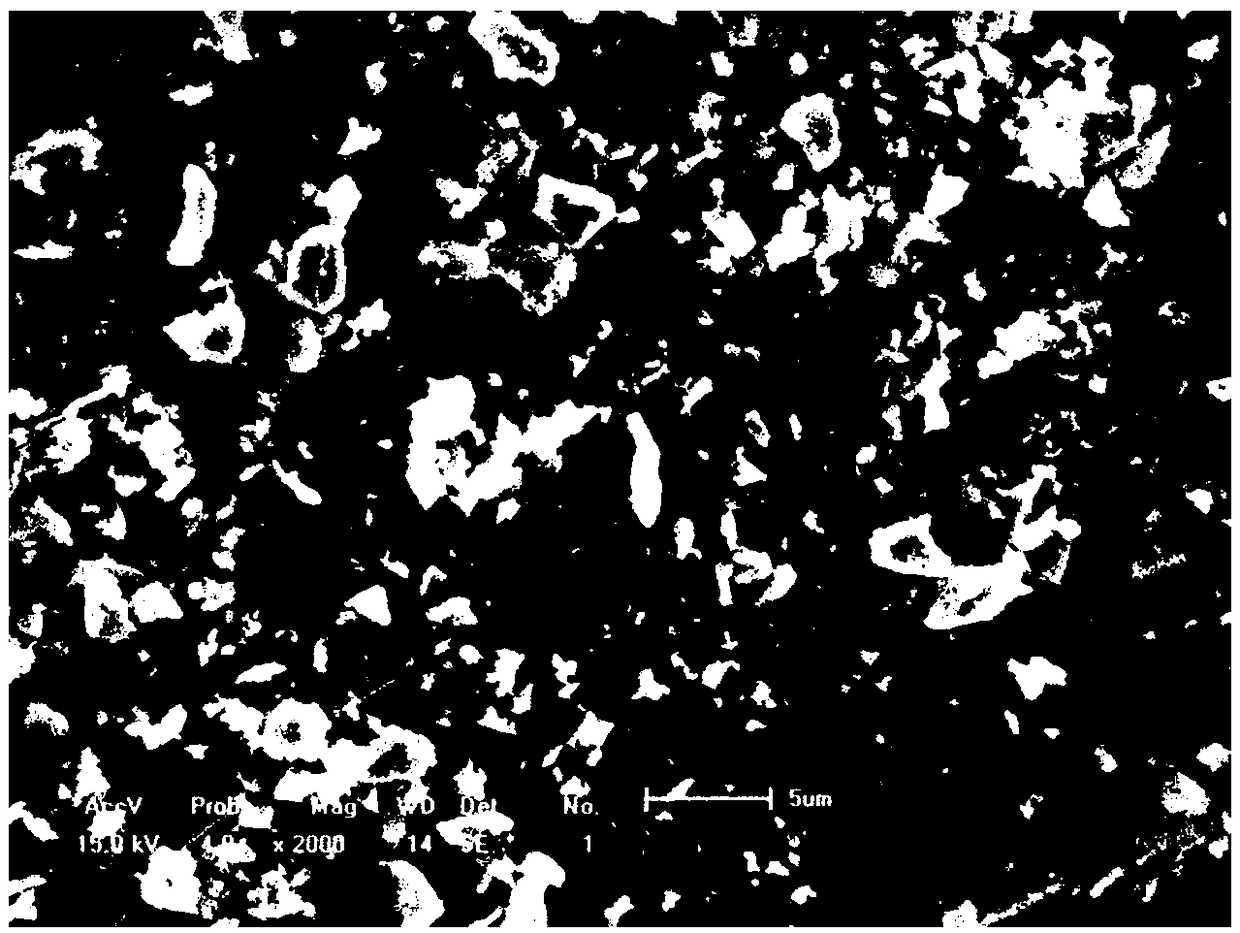

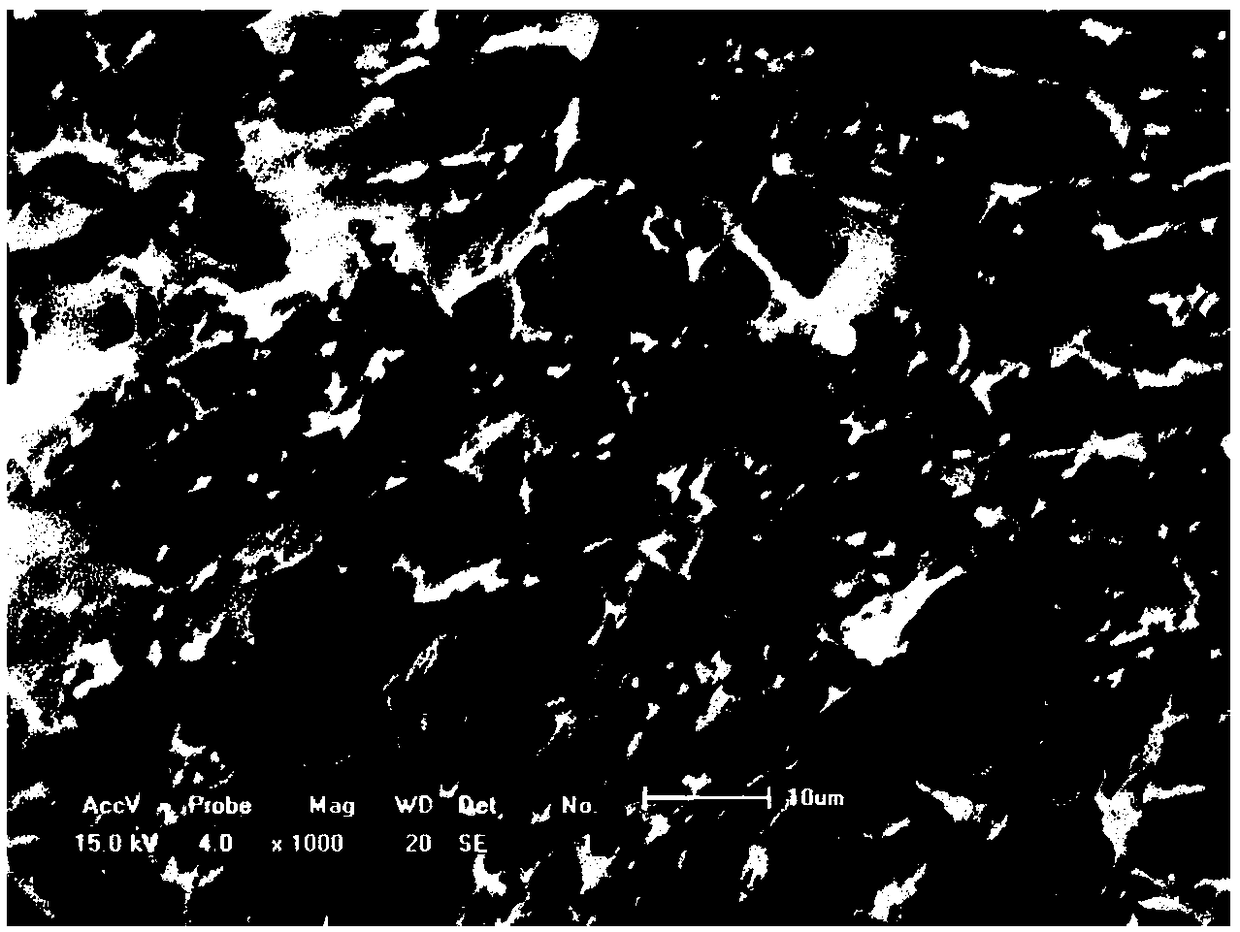

[0030] A kind of preparation method of sulfur autotrophic denitrifying bacteria immobilized granule that the present invention proposes, comprises the following steps:

[0031] S1. Add 10g of polyvinyl alcohol and 0.67g of xanthan gum into 100ml of deionized water, heat and stir at a temperature of 40°C, and obtain a mixed solution after fully dissolving and cooling to room temperature. Add 0.7g of a particle size of 60 The purpose rice husk is placed in 2ml of bacterial solution with a sludge sedimentation ratio of 20%. After hanging the film in a constant temperature incubator for 24 hours, it is added to the mixed solution together with 10g of pyrite with a particle size of 100 mesh and stirred evenly. forming material A;

[0032]S2. Melt 50 g of boric acid and 10 g of calcium chloride into 1000 ml of deionized water, heat to fully dissolve, then cool at room temperature until the boric acid is saturated and precipitated, and use 0.5 mol / L of sodium hydroxide solution to ad...

Embodiment 2

[0035] A kind of preparation method of sulfur autotrophic denitrifying bacteria immobilized granule that the present invention proposes, comprises the following steps:

[0036] S1. Add 10g of polyvinyl alcohol and 0.67g of xanthan gum into 100ml of deionized water, heat and stir at a temperature of 50°C, and obtain a mixed solution after fully dissolving and cooling to room temperature. The purpose rice husk is placed in 1ml of bacterial solution with a sludge sedimentation ratio of 30%. After hanging the film in a constant temperature incubator for 36 hours, it is added to the mixed solution together with 5g of pyrite with a particle size of 140 mesh. After stirring evenly forming material A;

[0037] S2. Melt 25g of boric acid and 5g of calcium chloride into 500ml of deionized water, heat to fully dissolve, then cool at room temperature until the boric acid is saturated and precipitated, use 0.3mol / L sodium hydroxide solution to adjust the pH to 7.2, The supernatant was tak...

Embodiment 3

[0040] A kind of preparation method of sulfur autotrophic denitrifying bacteria immobilized granule that the present invention proposes, comprises the following steps:

[0041] S1. Add 8g of polyvinyl alcohol and 0.67g of xanthan gum into 100ml of deionized water, heat and stir at a temperature of 40°C, and obtain a mixed solution after fully dissolving and cooling to room temperature. Add 0.35g of a particle size of 60 The purpose rice husk is placed in 1ml of bacterial solution with a sludge sedimentation ratio of 20%. After hanging the film in a constant temperature incubator for 12 hours, it is added to the mixed solution together with 5g of pyrite with a particle size of 100 mesh and stirred evenly. forming material A;

[0042] S2. Melt 25g of boric acid and 5g of calcium chloride into 500ml of deionized water, heat to fully dissolve, then cool at room temperature until the boric acid is saturated and precipitated, use 0.3mol / L sodium hydroxide solution to adjust the pH t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com