Preparation method of Al doped ZnO ultrathin nanometer sheet sensitive material, and applications of Al doped ZnO ultrathin nanometer sheet sensitive material

A technology of sensitive materials and nanosheets, which is applied in the fields of analyzing materials, material analysis by electromagnetic means, measuring devices, etc., can solve the problems of long response-recovery time, high detection limit, high working temperature, and achieves clean and pollution-free process. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

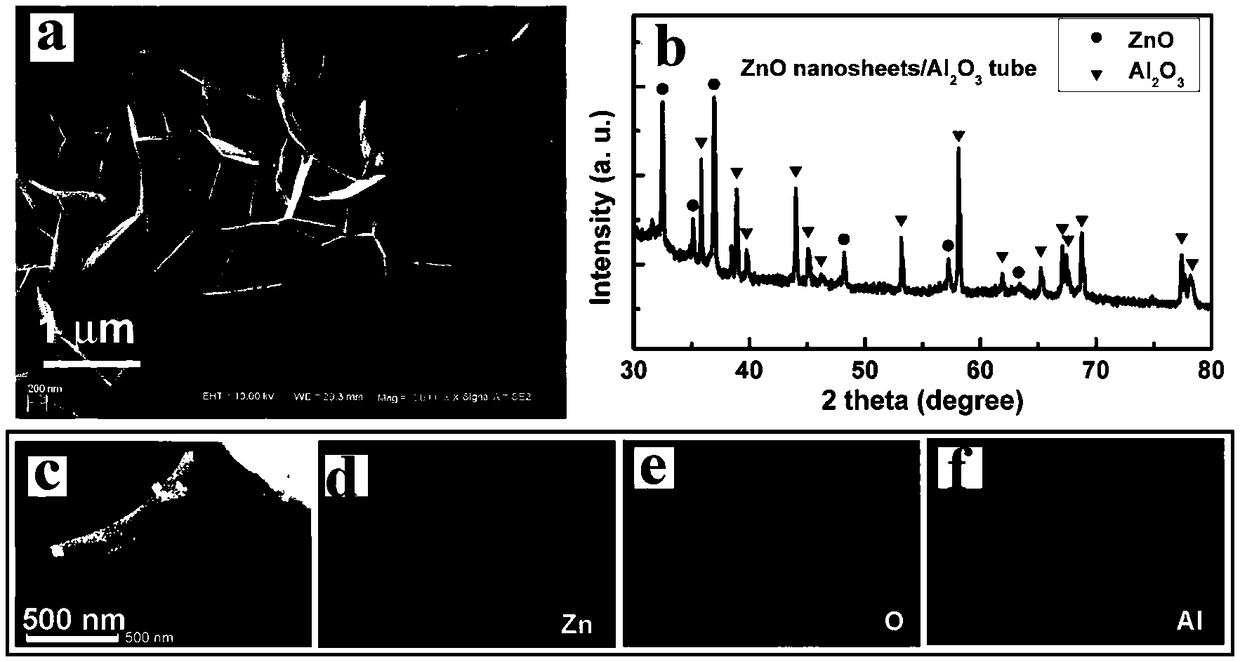

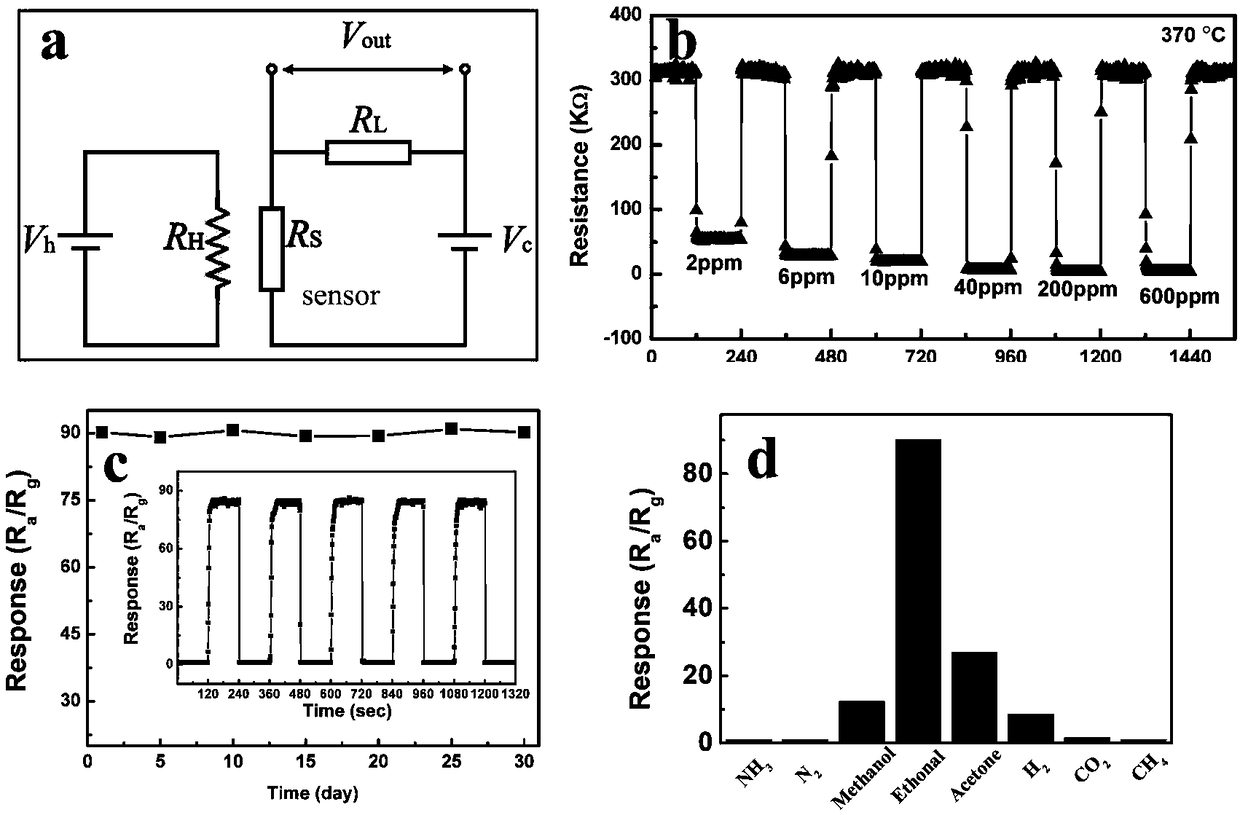

[0016] The preparation process of an Al-doped ZnO ultra-thin nanosheet sensitive material for ethanol gas sensor is as follows:

[0017] The preparation of the Al nano-intermediate layer grown on the ceramic tube: first put the ceramic tube into a beaker, and use ultrapure water, ethanol, acetone, and ultrapure water to perform ultrasonic cleaning for 10 minutes. Then a metal Al target with a purity of 99.99% was used, and the background vacuum was 1×10 -4 Pa, the DC sputtering power is 100W, the argon flow is 15sccm, the sputtering pressure is 1Pa, the target base distance is 8cm, the substrate is not heated, the pre-sputtering is 20min, and the sputtering time is 30s, and the surface growth Al nano-interlayer is obtained. of ceramic tubes.

[0018] Then put the ceramic tube with the Al nano-intermediate layer into the beaker, pour 0.5mol / L zinc acetate methanol solution, ultrasonically clean it for 10min, then put the ceramic tube into the crucible, and place it in a muffle...

Embodiment 2

[0027]The preparation process of an Al-doped ZnO ultra-thin nanosheet sensitive material for ethanol gas sensor is as follows:

[0028] The preparation of the Al nano-intermediate layer grown on the ceramic tube: first, put the ceramic tube into a beaker and use ultrapure water, ethanol, acetone, and ultrapure water to perform ultrasonic cleaning for 5 minutes. Then a metal Al target with a purity of 99.99% was used, and the background vacuum was 1×10 -4 Pa, the DC sputtering power is 150W, the argon flow rate is 30sccm, the sputtering pressure is 0.5Pa, the distance between the target and the base is 6cm, the substrate is not heated, the pre-sputtering is 15min, and the sputtering time is 1min. layers of ceramic tubes.

[0029] Then put the ceramic tube with the Al nano-intermediate layer into the beaker, pour 0.5mol / L zinc acetate methanol solution, ultrasonically clean it for 5min, then put the ceramic tube into the crucible, and set the temperature at 200°C Grow the seed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com