Preparation method and application of sodium-ion-embedded manganese dioxide/nitrogen-doped porous carbon composite material

A technology of nitrogen-doped porous carbon and manganese dioxide, which is applied in the manufacture of hybrid/electric double-layer capacitors and electrodes of hybrid capacitors, can solve the problems of low capacitance retention and poor rate performance, and achieve increased porosity and high porosity , the effect of uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

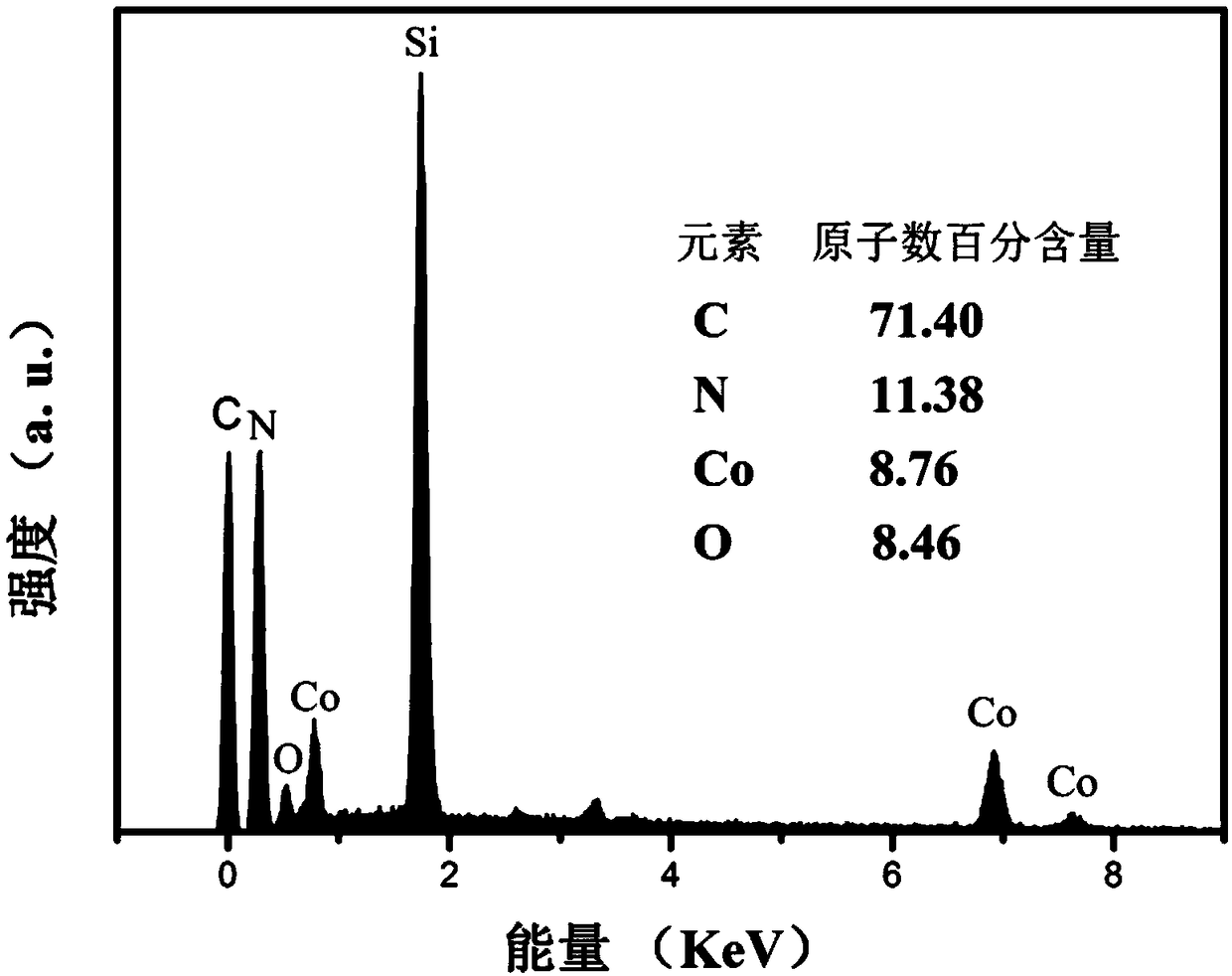

[0054] Embodiment 1: This embodiment is a method for preparing a sodium ion-embedded manganese dioxide / nitrogen-doped porous carbon composite material, which is prepared according to the following steps:

[0055] 1. Preparation of dodecahedral ZIF-67:

[0056] 1. Dissolving cobalt nitrate hexahydrate in methanol to obtain cobalt nitrate solution;

[0057] The mass of cobalt nitrate hexahydrate described in step 1. and the volume ratio of methanol are (1g~2g): 40mL;

[0058] ②, dissolving 2-methylimidazole in methanol to obtain a 2-methylimidazole solution;

[0059] The mass of the 2-methylimidazole described in step 1.2 and the volume ratio of methanol are (1g~3g): 40mL;

[0060] ③. Mix cobalt nitrate solution and 2-methylimidazole solution, then stir and react at room temperature and stirring speed at 500r / min-900r / min for 15h-25h, then carry out vacuum filtration to collect solid matter; use absolute ethanol Wash the collected solid matter for 5 to 8 times, and then put t...

specific Embodiment approach 2

[0085] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of the mass of cobalt nitrate hexahydrate described in Step ① to methanol is (1.6g-2g): 40mL. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0086] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the mass of 2-methylimidazole described in step ② to methanol is (1g-2g):40mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com