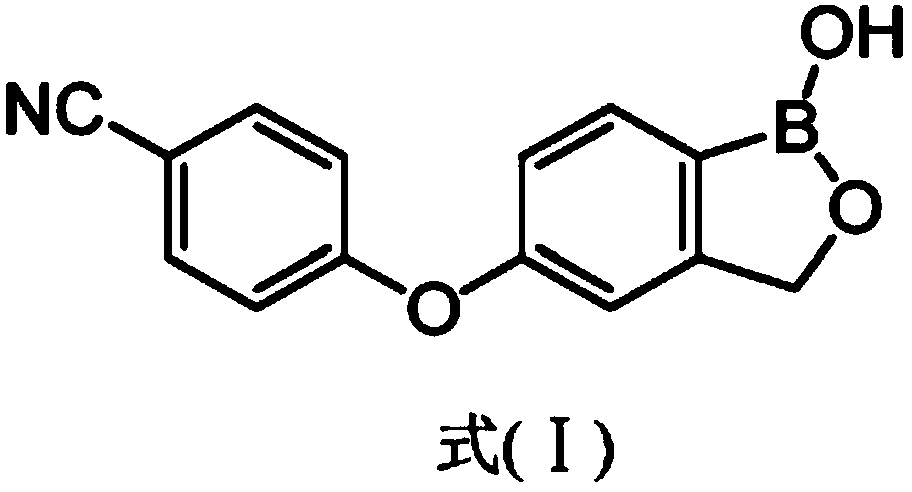

Crisaborole sustained-release film with good paste effect and preparation method thereof

A technology of criborole and sustained-release film, which is applied in the field of biomedical materials, can solve the problems of not being able to be retained for a long time and being easily wiped, and achieve the effect of good sustained-release treatment effect and strong binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

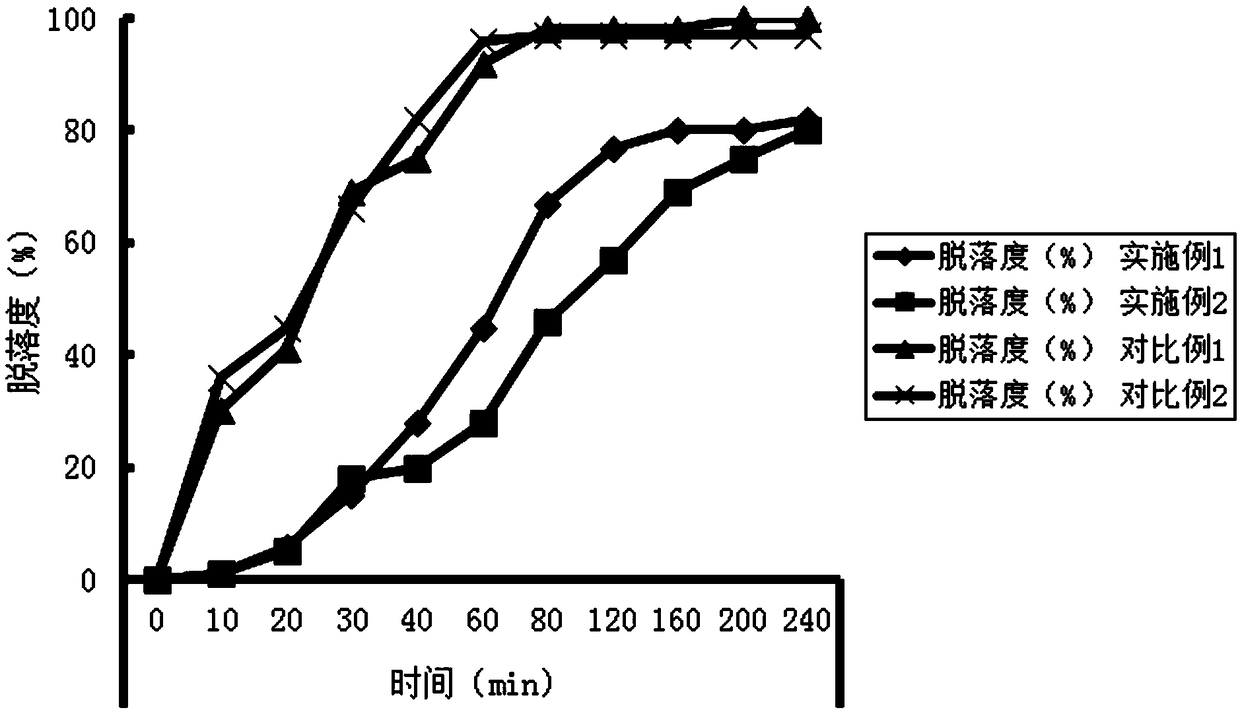

Examples

Embodiment 1

[0027] A, the first layer of sustained-release film preparation: with crisborole 20%, glycerin 25%, microcrystalline cellulose 25%, propylene glycol 7%, carrageenan 8%, adhesive agent 15% (by polyvinylpyrrolidone 60%, 10% polycarbophil, 10% rosin, 10% polyvinyl alcohol and 10% cornstarch) mixed fully, melted, extruded film-forming agent with extruder;

[0028] B, the second layer of delayed-release film preparation: with 20% of crisborole, 25% of propylene alcohol, 25% of sorbitol, 7% of polysorbate, 8% of guar gum, 15% of binding agent (by polyvinylpyrrolidone 60%, polycarbophil 10%, rosin 10%, polyvinyl alcohol 10% and cornstarch 10%) mixed fully, add appropriate amount of water to dissolve, stir evenly, apply it evenly on the above slow-release film, dry Machine drying until there is no obvious moisture, and the drying temperature is 60°C;

[0029] C. Cut and get.

Embodiment 2

[0031] A, the preparation of the first layer of slow-release film: with crisborole 25%, polyethylene glycol 23%, modified starch 22%, menthol 8%, sodium carboxymethyl cellulose 7%, binding agent 15% (by 60% polyvinylpyrrolidone, 10% polycarbophil, 10% rosin, 10% polyvinyl alcohol and 10% cornstarch) are fully mixed, melted, and extruded film-forming agent with an extruder;

[0032] B, the preparation of the second layer of delayed-release film: with crisborole 25%, glyceryl triacetate 23%, dextrin 22%, menthol 8%, sodium carboxymethyl cellulose 7%, binding agent 15% (by 60% polyvinylpyrrolidone, 10% polycarbophil, 10% rosin, 10% polyvinyl alcohol and 10% cornstarch) mixed well, add appropriate amount of water to dissolve, stir evenly, and spread it evenly on the above slow-release film , the dryer is dried until there is no obvious moisture, and the drying temperature is 60°C;

[0033] C. Cut and get.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com