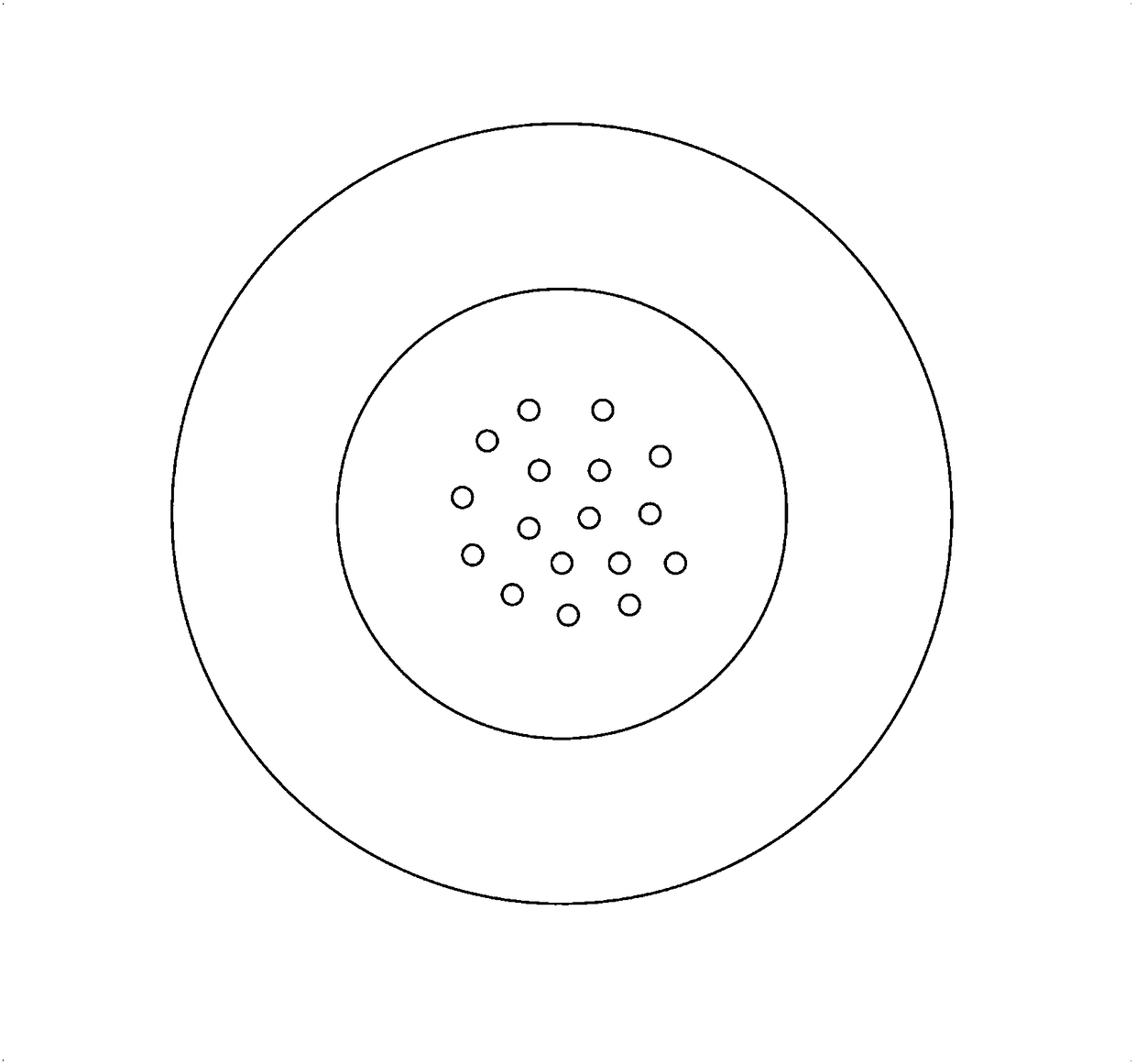

Nuclear microporous membrane for atomizer plate and making method of nuclear microporous membrane

A technology of nuclear microporous membrane and atomized tablet, which is applied in the field of drug atomization treatment and nuclear microporous membrane ultrasonic atomized tablet, which can solve the problem of low concentration of atomized aerosol, difficulty in large-dose administration, and insufficient aerosol particle size Small and other problems, to avoid excessive temperature and improve the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Kr particles with an energy of 10 MeV / u irradiate a polycarbonate film with a thickness of 10 μm to form a track density of 2×10 6 / cm 2 Submerged track membrane;

[0051] 2) Print a layer of nitrocellulose layer on one side (side A) of the latent track membrane, and the printing thickness range is 0.5 μm;

[0052] 3) Vacuum-deposit an aluminum layer with a certain thickness on the surface A of the latent track film, with a thickness ranging from 0.01 to 0.1 μm;

[0053] 4) After compounding the surface A of the creeping track film with the film with adhesive, soak in 5mol / L sodium hydroxide solution at 70°C until the aluminum layer completely disappears, take out the creeping track film, and put the composite The adhesive film is torn off and removed;

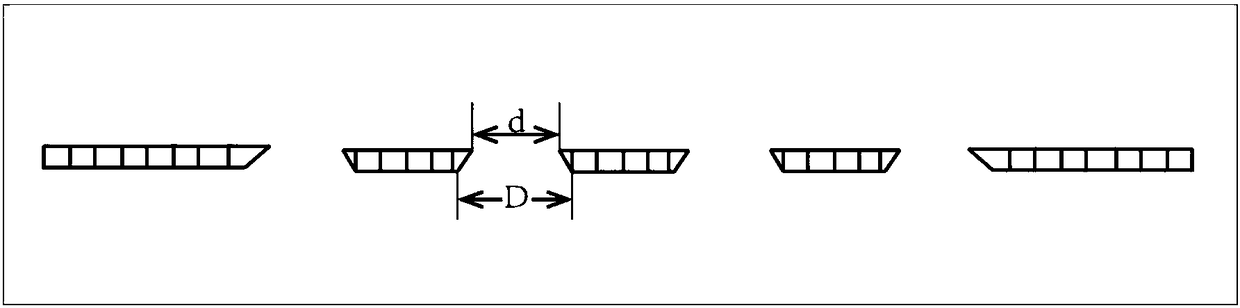

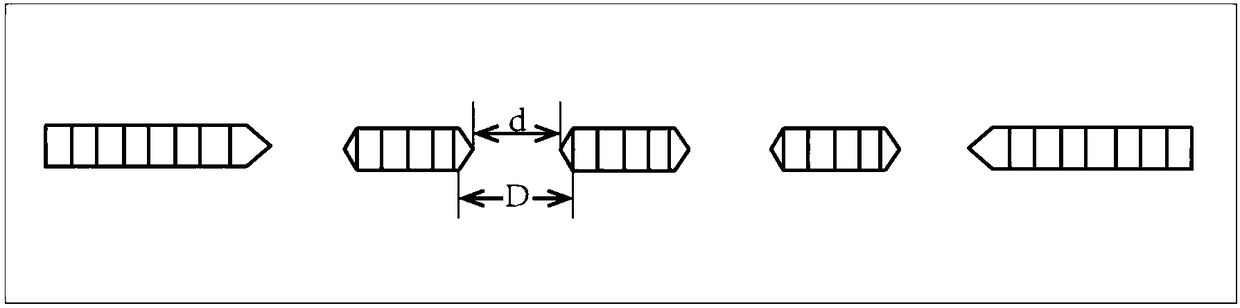

[0054] 5) Cleaning and drying, that is, the thickness is 8 μm, d=1 μm, D=3Mm, ρ=2×10 6 / cm 2 Single-cone nuclear microporous membrane;

[0055] 6) Cutting the nuclear microporous membrane of the single cone por...

Embodiment 2

[0062] 1) Kr particles with an energy of 10 MeV / u irradiate a polyester film with a thickness of 20 μm to form a track density of 2×10 5 / cm 2 Submerged track membrane;

[0063] 2) Print a layer of nitrocellulose on one side (side A) of the latent track membrane, and the printing thickness range is 1 μm;

[0064] 3) Vacuum-deposit an aluminum layer with a certain thickness on the surface A of the latent track film, with a thickness ranging from 0.01 to 0.1 μm;

[0065] 4) After compounding the surface A of the latent track film with the film with adhesive, soak it in 8mol / L potassium hydroxide + 1% potassium permanganate solution at 65°C, and observe the aluminum layer on the film When the aluminum layer disappears completely, the submerged track film is taken out, and the composite adhesive film is torn off and removed;

[0066] 5) Washing and drying, that is, the thickness is 15 μm, d=3 μm, D=10 μm, ρ=2×10 5 / cm 2 Single-cone nuclear microporous membrane;

[0067] 6) C...

Embodiment 3

[0074] 1) Kr particles with an energy of 10 MeV / u irradiate a polyimide film with a thickness of 40 μm to form a track density of 8×10 4 / cm 2 Submerged track membrane;

[0075] 2) Print a layer of nitrocellulose layer on one side (side A) of the latent track membrane, and the printing thickness range is 0.5 μm;

[0076] 3) After compounding the surface A of the latent track film with the film with adhesive, soak in 6mol / L potassium permanganate solution at 80°C for 30 minutes, take out the latent track film, and put the composite film with adhesive torn apart;

[0077] 4) Washing and drying, that is, the thickness is 32 μm, d=8 μm, D=15 μm, ρ=8×10 4 / cm 2 Single-cone nuclear microporous membrane;

[0078] 5) Cutting the prepared nuclear microporous membrane 2 into a membrane having the same diameter as the outer diameter of the annular piezoelectric ceramic;

[0079] 6) Apply a ring-shaped adhesive on the surface of the small hole of the membrane, the outer diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com