Method for extracting syringic acid and recovering ionic liquid by using ionic liquid aqueous two-phase system

A two-phase system, ionic liquid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of complex extraction and recovery system construction, less application of two-phase system, toxic recovery of ionic liquids, etc. Achieve the effect of easy operation, short phase separation time, and easy amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

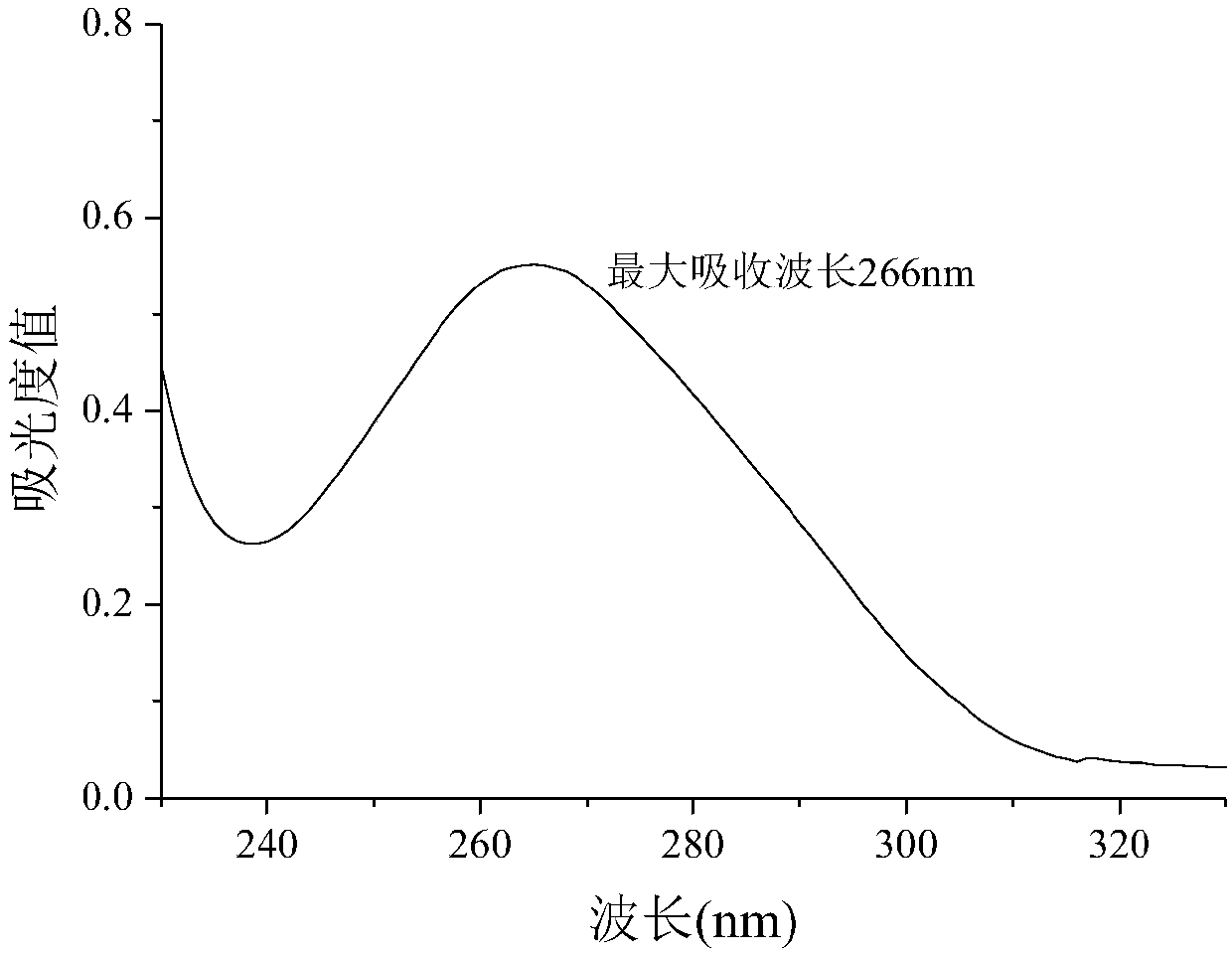

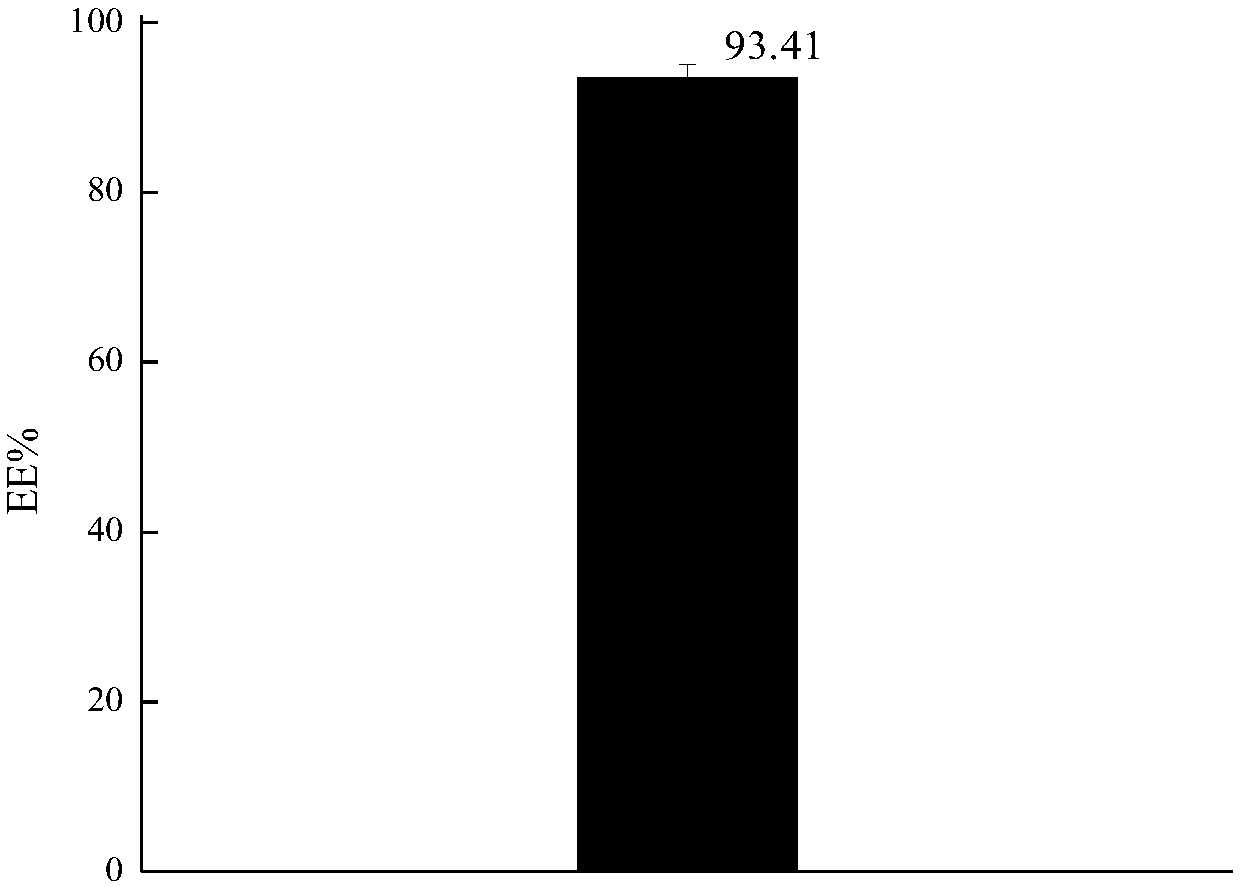

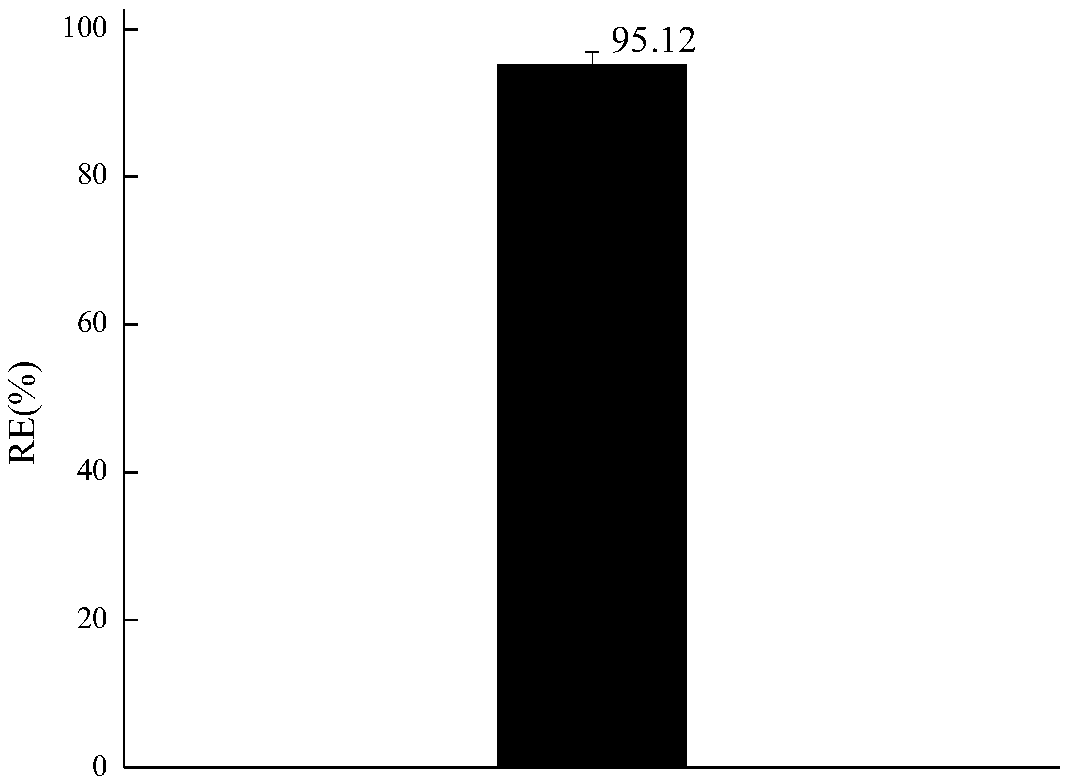

[0028] (1) Take 1.0g of 1-butyl-3-methylimidazolium trifluoromethanesulfonate in a centrifuge tube, then weigh 0.8gNa 2 CO 3 Add to the centrifuge tube, followed by adding 1g concentration of 3×10 -3 mol / L syringic acid solution, and finally add 7.2g of distilled water to supplement the total mass of the two-phase system to 10g to obtain an ionic liquid / sodium carbonate two-phase system. In order to test the accuracy of the data, each sample was equipped with three groups for parallel experiments.

[0029] (2) Shake the ionic liquid / sodium carbonate two-phase system obtained in step (1) with a vortex shaker for 5 minutes, then put it in a constant temperature water bath at 25°C and let it stand for 24 hours. The system is divided into an ionic liquid enriched phase and an inorganic salt enriched phase; syringic acid is extracted into the inorganic salt phase, and the extraction rate of syringic acid in the inorganic salt enriched phase is further calculated; the ionic liquid...

Embodiment 2

[0031] (1) Take 2.0g of 1-butyl-3-methylimidazolium trifluoromethanesulfonate in a centrifuge tube, then weigh 1g of Na 2 CO 3 Add to the centrifuge tube, followed by adding 1g concentration of 3×10 -3 mol / L syringic acid solution, and finally add 6g of distilled water to supplement the total mass of the two-phase system to 10g to obtain an ionic liquid / sodium carbonate two-phase system. In order to test the accuracy of the data, each sample was equipped with three groups for parallel experiments.

[0032] (2) Shake the configured ionic liquid / sodium carbonate two-phase system with a vortex shaker for 5 minutes, put it in a constant temperature water bath at 25°C and let it stand for 24 hours. The system is divided into an ionic liquid enriched phase and an inorganic salt enriched phase The syringic acid is extracted to the inorganic salt phase, and the extraction rate of the syringic acid in the inorganic salt-rich phase is further calculated; the ionic liquid phase can be ...

Embodiment 3

[0034] (1) Take 2.2g of 1-butyl-3-methylimidazolium trifluoromethanesulfonate in a centrifuge tube, then weigh 1.6g of Na 2 CO 3 Add to the centrifuge tube, followed by adding 1g concentration of 3×10 -3 mol / L syringic acid solution, and finally add 5.2g of distilled water to replenish the total mass of the two-phase system to 10g, to obtain an ionic liquid / sodium carbonate two-phase system. In order to test the accuracy of the data, each sample was equipped with three groups for parallel experiments.

[0035] (2) Shake the completed ionic liquid / sodium carbonate two-phase system with a vortex shaker for 5 minutes, put it in a constant temperature water bath at 25°C and let it stand for 24 hours. The system is divided into an ionic liquid-rich phase and an inorganic salt-rich phase. Syringic acid is extracted into the inorganic salt phase, and the extraction rate of syringic acid in the inorganic salt enriched phase is further calculated, and the ionic liquid enriched phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com